Ultrasonic excitation-assisted hydraulic fracturing pressure relief method for improving permeability in underground coal mine

An ultrasonic excitation and hydraulic fracturing technology, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve problems such as production replacement tension, achieve low cost, safe and reliable process, and save pre-extraction drilling engineering. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The 222 working face of an outburst mine is a single 1 Coal seam mining, the occurrence of coal seam in the working face is stable, there are no faults, caves, collapse columns, folds and other geological structures; the strike length of the working face is 1400m, the inclination length is 220m, the average thickness of the coal seam is 4.5m, and the inclination angle of the coal seam is 8°; the gas content of the coal seam in the working face is 6.5 ~10.7m 3 / t, gas pressure 0.5~1.2MPa, coal seam permeability coefficient 0.022~0.053m 2 / (MPa 2 · d), which belongs to the difficult-to-drain coal seam; the working face adopts the anti-outburst measures in the coal seam gas area of the coal seam gas area in the pre-drainage mining area by drilling along the bedding, and the spacing of the holes is 4m.

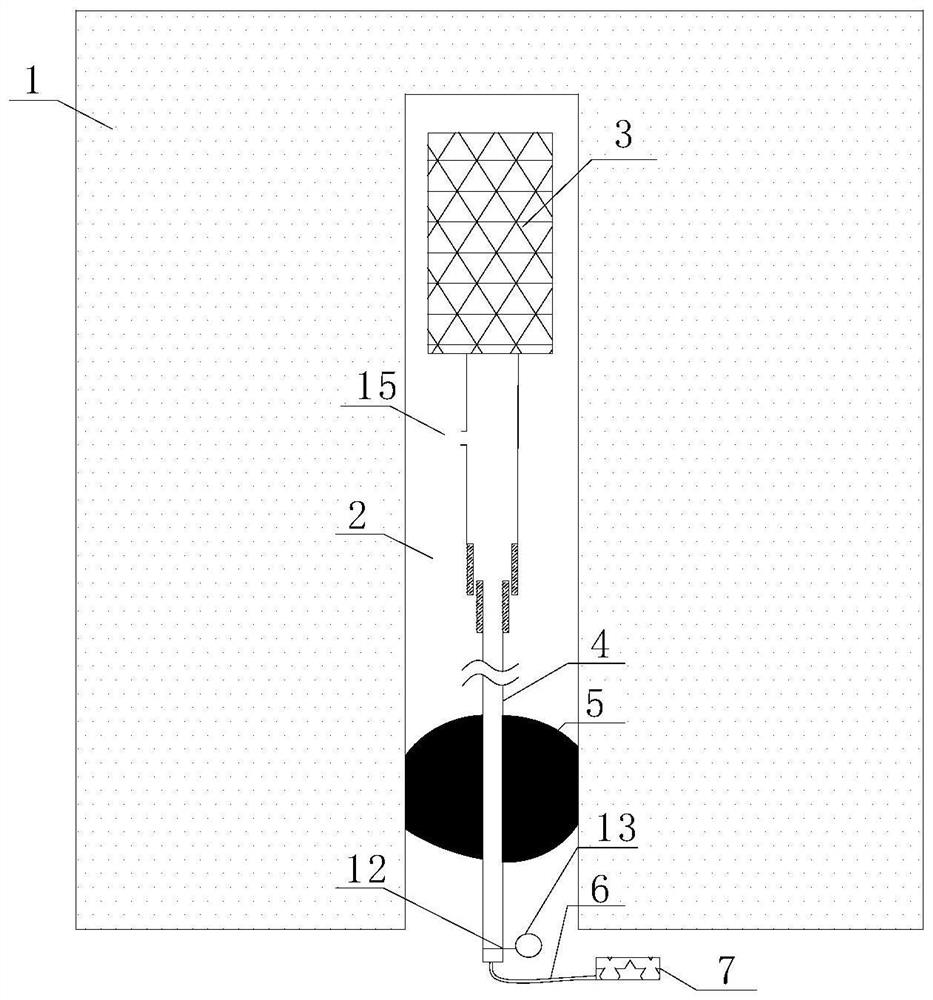

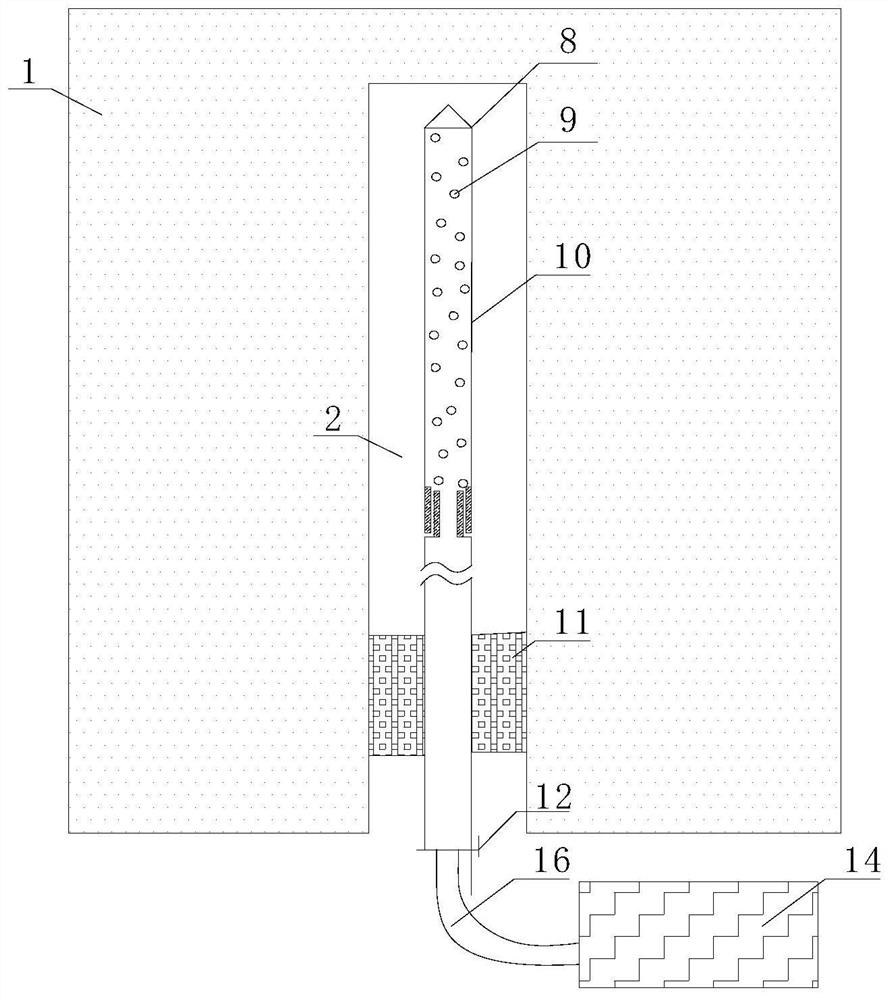

[0038] Such as figure 1 , figure 2 As shown, a kind of coal mine underground ultrasonic excitation assisted hydraulic fracturing depressurization anti-permeability m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com