A kind of highly organic sulfur-tolerant Thioalkali halophilus and its cultivation method and application in biological desulfurization

A biological desulfurization and organic sulfur technology, applied in the direction of microorganism-based methods, microorganisms, microorganisms, etc., can solve the problems of low tolerance, difficult treatment, and restrictions on the promotion and application of technologies, so as to improve tolerance and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

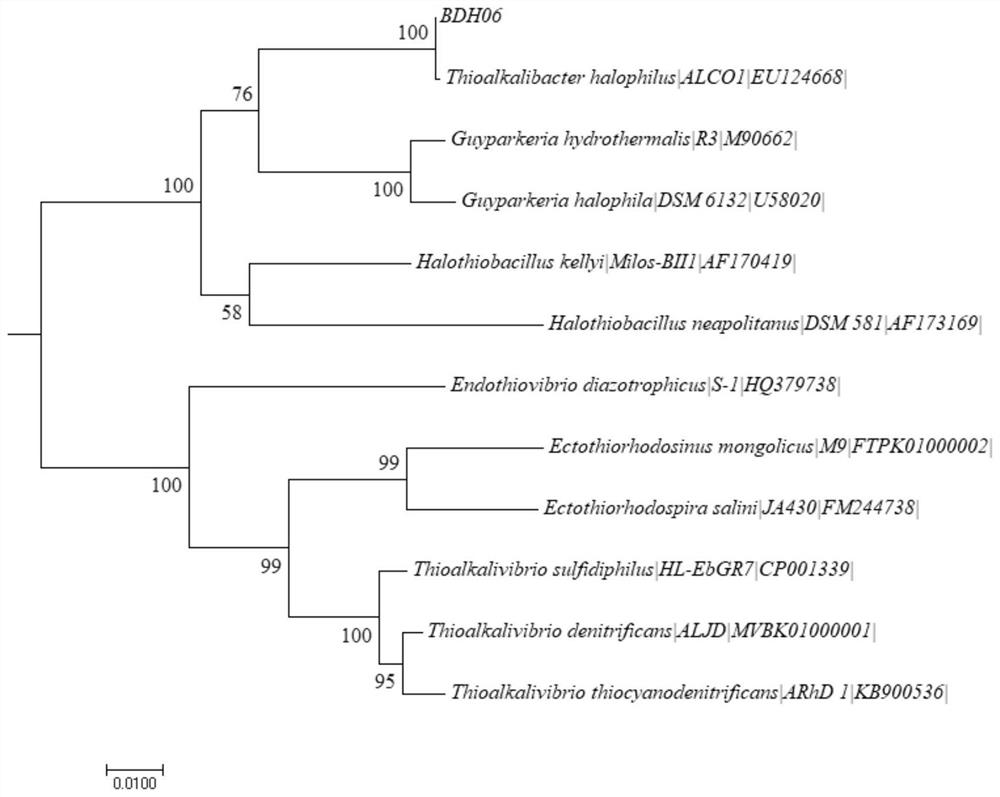

[0063] This example provides a method for screening and isolating Thioalkali halophilus BDH06, which is highly tolerant to organic sulfur, and the operation is as follows:

[0064] (1) Collect the sediments from the shore of the saline-alkali lake in Badain Jaran Desert, Inner Mongolia, take 1g of the sample and place it in 100mL of sodium thiosulfate liquid medium, and culture it on a shaking table at 30°C and 150rpm for 60h;

[0065] (2) Take 1 mL of the suspension and inoculate it into 100 mL of sodium thiosulfate liquid medium, and continue to culture at 30°C and 150 rpm on a shaker for 60 h;

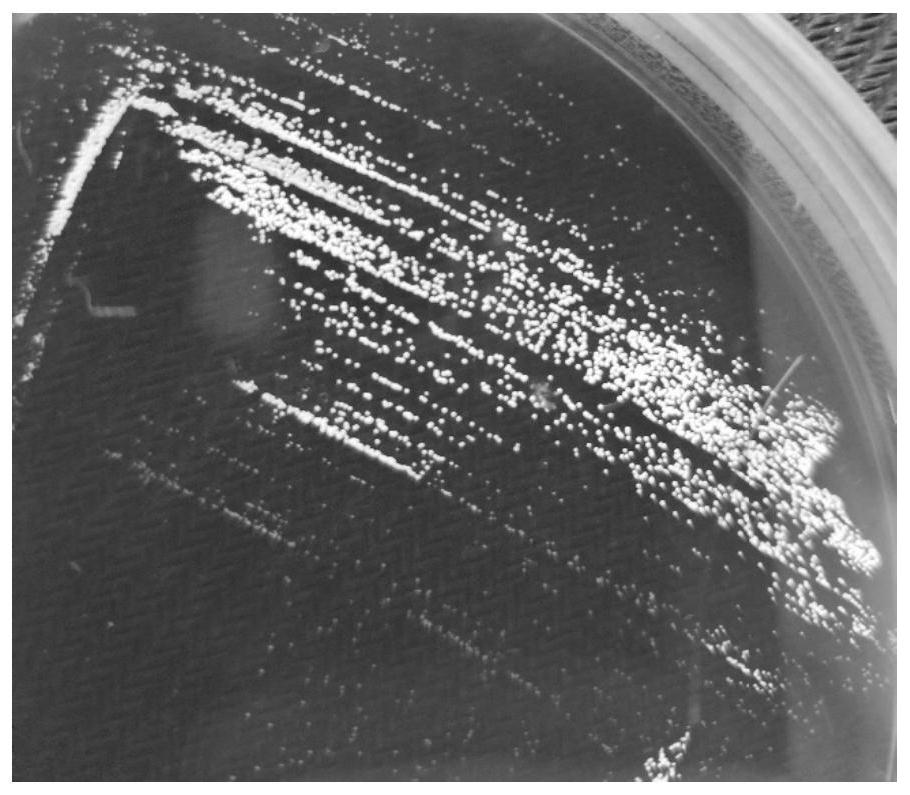

[0066] (3) Take 100 μL of the suspension and spread it on the surface of the sodium thiosulfate solid medium, culture it at 30°C for 60 hours, and select white colonies for re-screening and identification;

[0067] Wherein, sodium thiosulfate liquid culture medium comprises following composition: 0.05mmol / L methyl mercaptan, 30g / L Na 2 S 2 o 3 , 30g / L NaHCO 3 , 5g / L NaOH, 10g / L ...

Embodiment 2

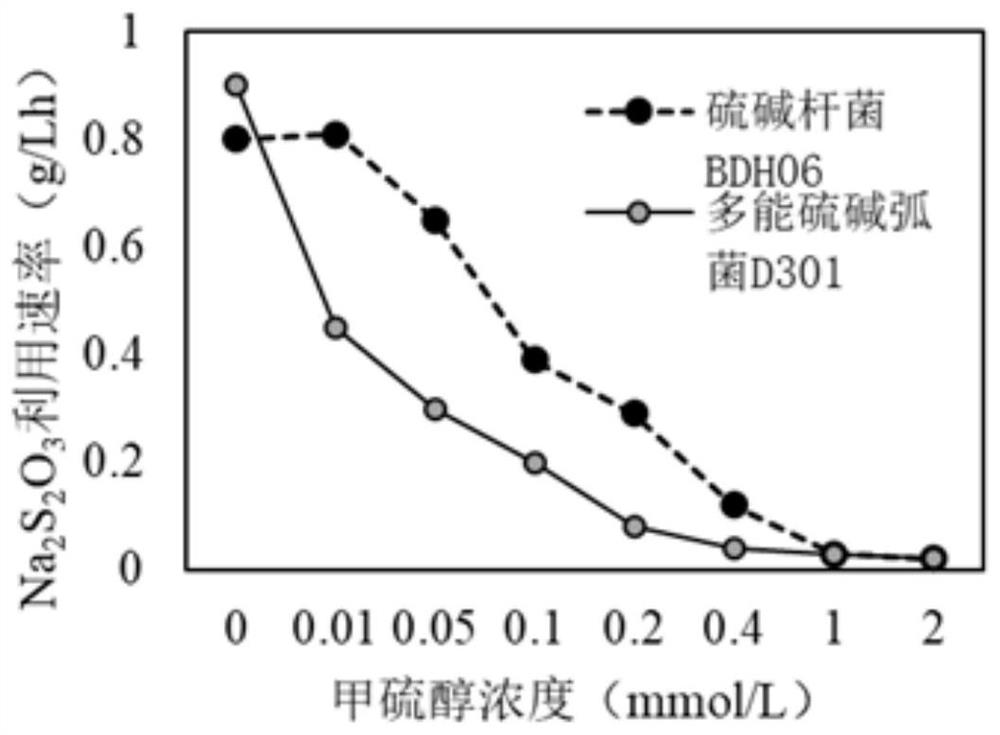

[0076] This example compares the tolerance to methyl mercaptan of Thioalkalibacterium halophilus BDH06 described in the present invention and the sulfoalkali vibrio pluripotent D301 (strain number CGMCC No.8497) disclosed in the patent No. CN201410061877.1, the operation is as follows :

[0077] Take 1 mL of the two activated bacterial solutions and inoculate them in sodium thiosulfate liquid medium (100 mL, pH=9.5, sodium ion concentration: 1.0 M) containing different concentrations of methyl mercaptan respectively, shake on a shaker at 30°C and 150 rpm to cultivate. The final concentrations of methyl mercaptan in the culture medium were 0, 0.01mmol / L, 0.05mmol / L, 0.1mmol / L, 0.2mmol / L, 0.4mmol / L, 1.0mmol / L, 2.0mmol / L. After culturing for 48 hours, samples were taken, and the utilization rate of sodium thiosulfate was determined by ion chromatography.

[0078] The result is as image 3 Shown, the inhibition coefficient IC of methyl mercaptan to Thioalkali halophilus BDH06 ...

Embodiment 3

[0081] In this example, Thioalkali halophilus BDH06 is used for the treatment of hydrogen sulfide-containing gas, and the operation is as follows:

[0082] (1) Prepare the test gas containing hydrogen sulfide, which contains 5000ppm hydrogen sulfide and the rest is nitrogen.

[0083] (2) The hydrogen sulfide-containing gas is countercurrently passed through the absorption tower, during which the gas is in contact with the lye, wherein the hydrogen sulfide is absorbed by the lye to form a high-sulfur solution containing sodium hydrogen sulfide; the high-sulfur solution enters the bioreactor; In the reactor, by controlling the oxidation-reduction potential, Thioalkali halophilus BDH06 oxidizes hydrogen sulfide to elemental sulfur, and at the same time regenerates the lye for recycling;

[0084] The above-mentioned lye is a buffer solution prepared by sodium bicarbonate and sodium hydroxide, and the composition includes 30g / L NaHCO 3 , 5g / LNaOH, 10g / L NaCl, 0.5g / L NH 4 Cl, 0.5g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com