Different-pattern synchronous double-amplitude printing machine

A printing machine and different pattern technology, which is applied in the field of different pattern synchronous double-width printing machines, can solve the problems of reduced printing efficiency, achieve the effect of reducing the time for replacing the rotary screen and ensuring the printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

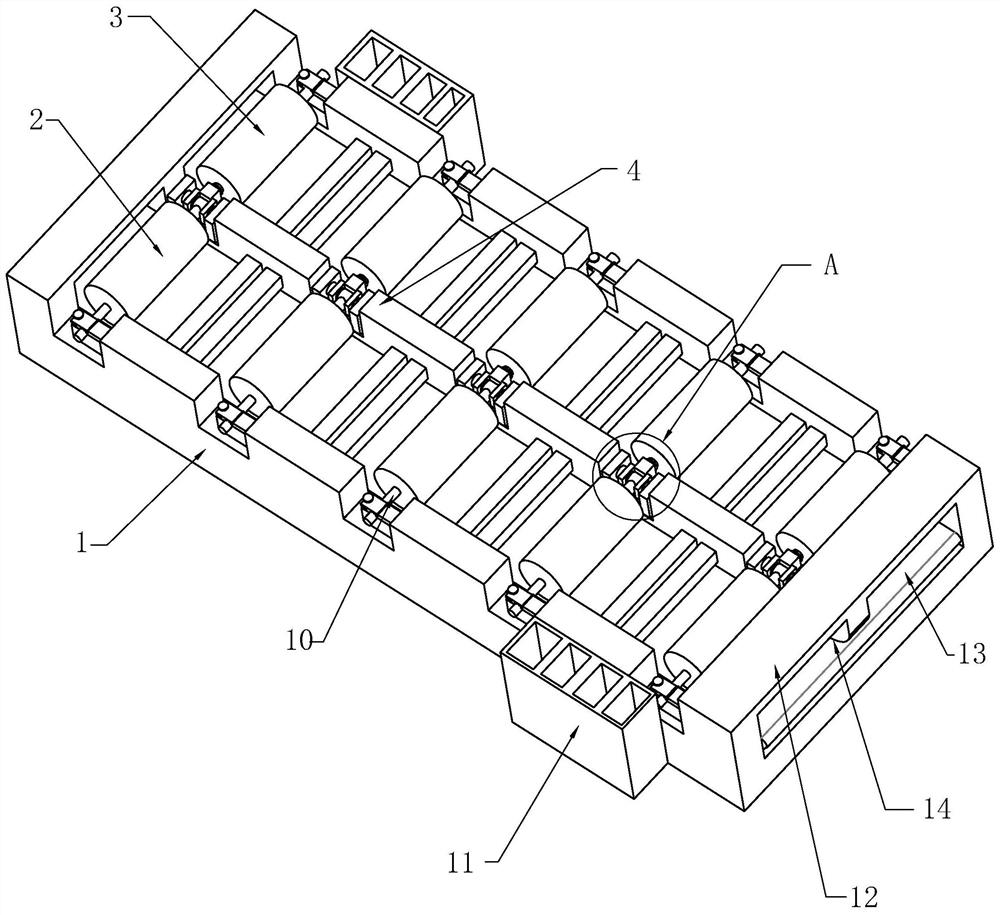

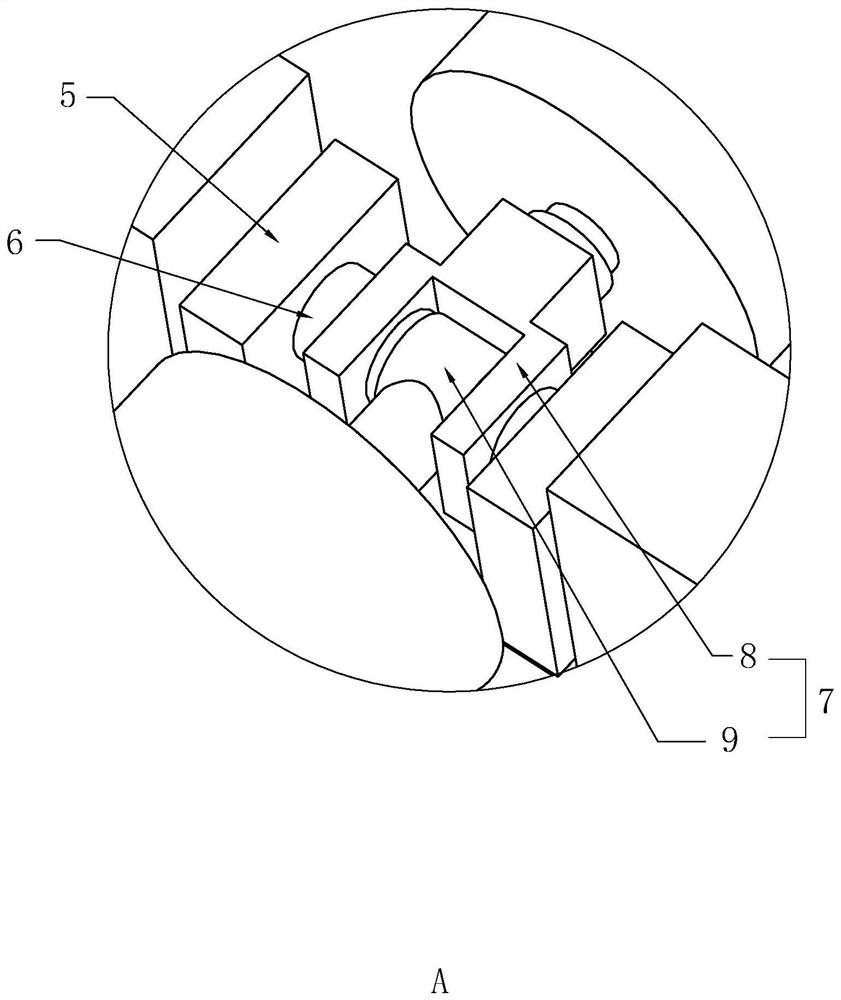

[0018] Different pattern synchronous double-width printing machine, including frame 1, the two sides of frame 1 are respectively equipped with group A rotary screen 2 and group B rotary screen 3, and the patterns printed by group A rotary screen 2 and group B rotary screen 3 are different .

[0019] A guide belt 13 is arranged on the frame 1 below the group A cylinder 2 and the B cylinder 3, and the guide belt 13 can drive the fabric to advance.

[0020] The front and rear ends of the frame 1 are uniformly provided with crossbars 12 spanning both sides, and between the crossbars 12, a partition wall 4 is arranged in the middle of the left and right sides of the frame 1, between the bottom of the partition wall 4 and the guide belt 13. There is a suspended part 14 between them, so that the fabrics on the group A cylinder 2 and the group B cylinder 3 can advan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com