A detection path planning method for multi-check features

A path planning and path technology, applied in forecasting, data processing applications, instruments, etc., can solve problems such as path repetition, repeated trial and error, and affecting the completion of production plans on time, so as to save measurement time and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

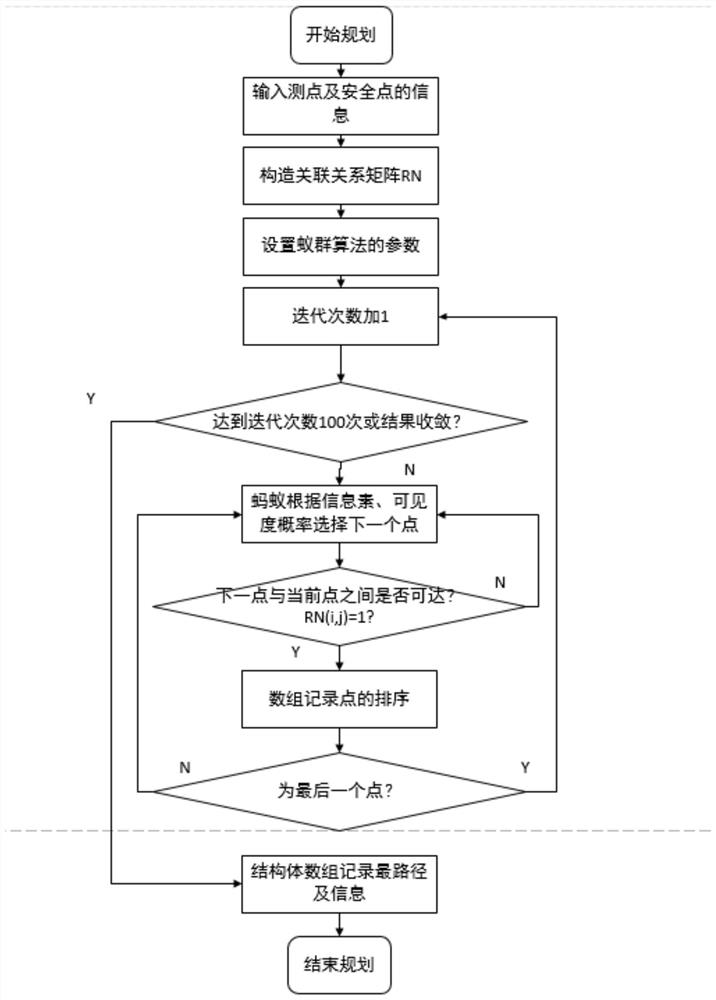

[0036] A detection path planning method for multi-check features, such as figure 1 shown, the specific steps are as follows:

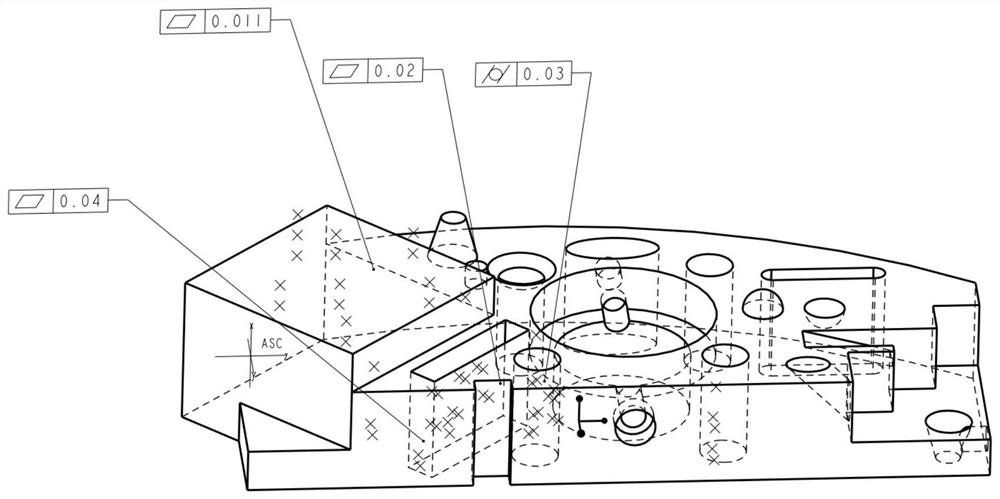

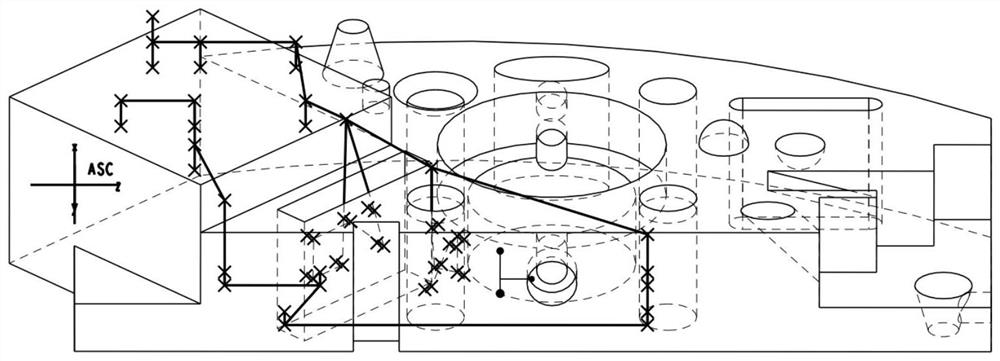

[0037] Step 1: Different from the conventional method of manually adding measuring points and safety points on the model according to the experience of the worker's master, the present invention analyzes the inspection information on the three-dimensional model, and detects the measuring points and the safety points according to the characteristics of geometric features and the requirements of geometric tolerance. The layout of the safety points, and record the coordinate value, direction vector and the identification number of the feature of each measuring point, and design the corresponding database table to store the measuring point information. Aiming at the cross-feature detection path planning problem concerned, taking the 3D model TEST_MODEL in Creo2.0 software as an example, the annotations on the model are analyzed, so as to plan the measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com