Closed explosion-proof tank

An explosion-proof tank and closed technology, which is applied in the direction of blasting, construction, building fastening devices, etc., can solve the problems of weak locking structure, large safety hazards of open explosion-proof tanks, and large safety hazards, and achieve excellent anti-explosion performance , the effect of reducing the lethal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

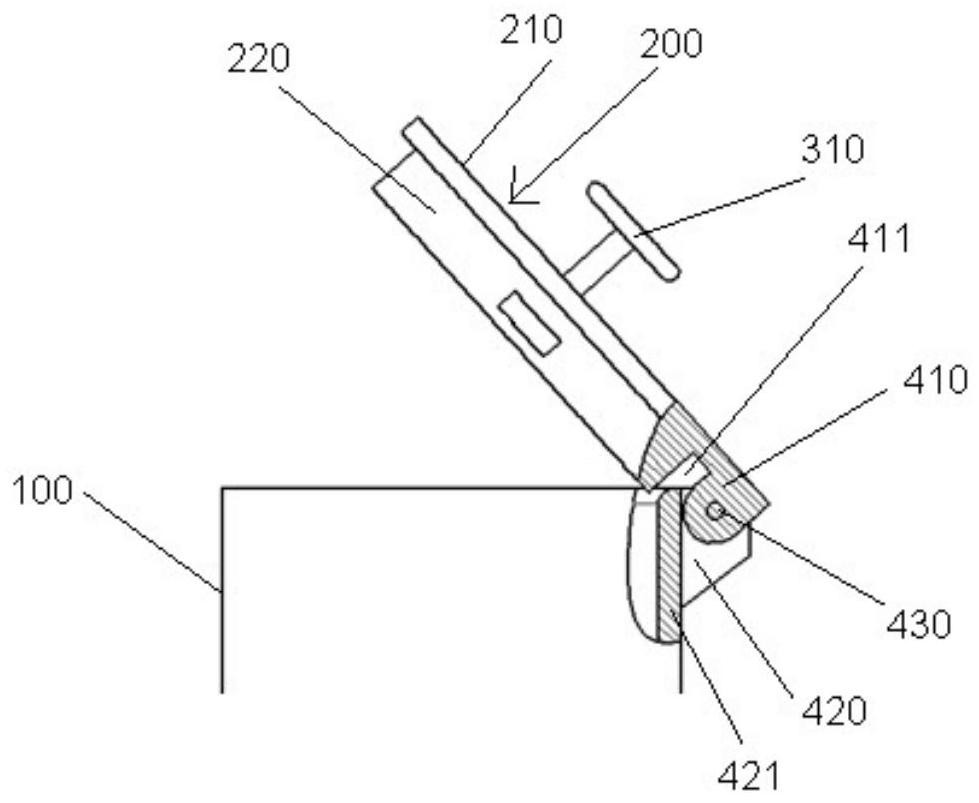

[0037] Such as Figure 1-4 As shown, a closed explosion-proof tank of this embodiment includes a tank body 100, a tank cover 200 and a locking mechanism. One side of the can cover 200 has a connecting plate 410, and the corresponding can body 100 has a connecting block 420, and the two are connected by a pin 430 to form a hinge structure. Through this hinge structure, the can body 100 and the can cover 200 are connected in rotation. That is, the can lid 200 rotates relative to the can body 100 around the pin 430 to realize the opening or closing of the can lid 200. The can lid 200 is integrally formed by a lid 210 and a lid 220. The diameter of the can 100 is between the diameter of the lid 210 and the diameter of the lid 220. In the closed state, the lid 210 is located above the can 100, and the lid 220 is embedded The inside of the tank body 100 fits with the inner wall of the tank body 100.

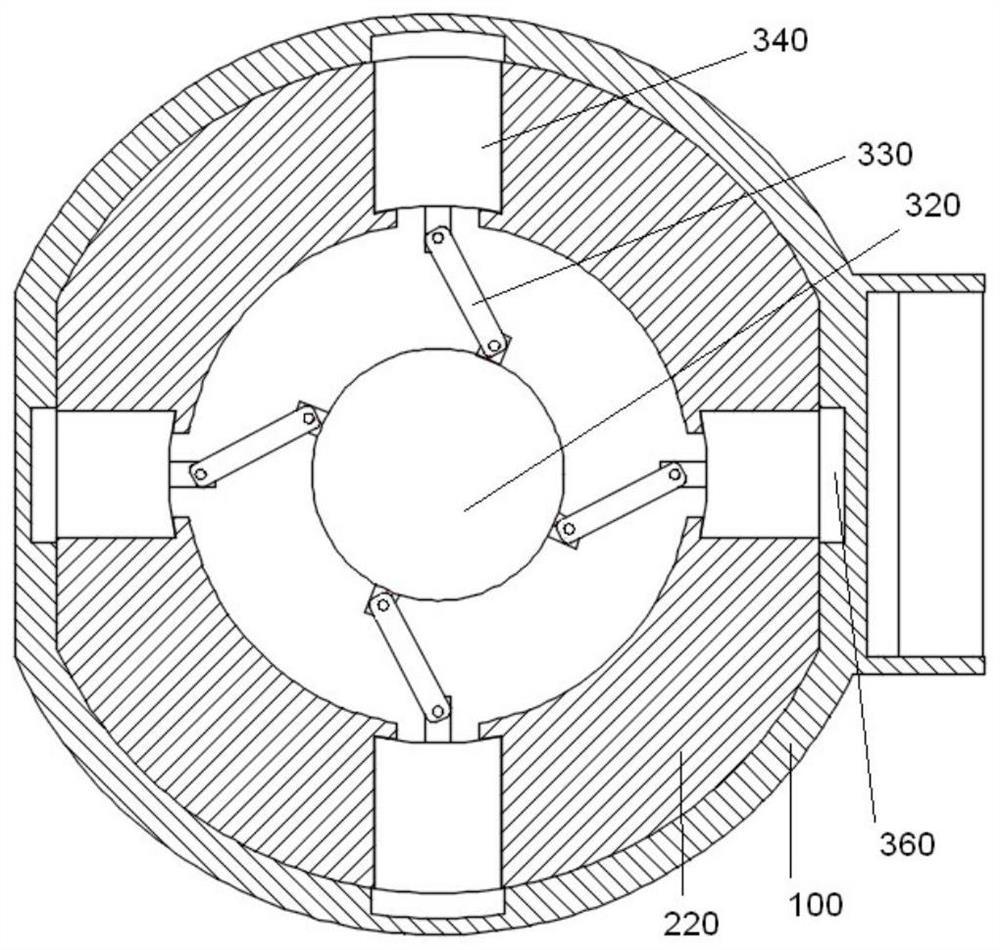

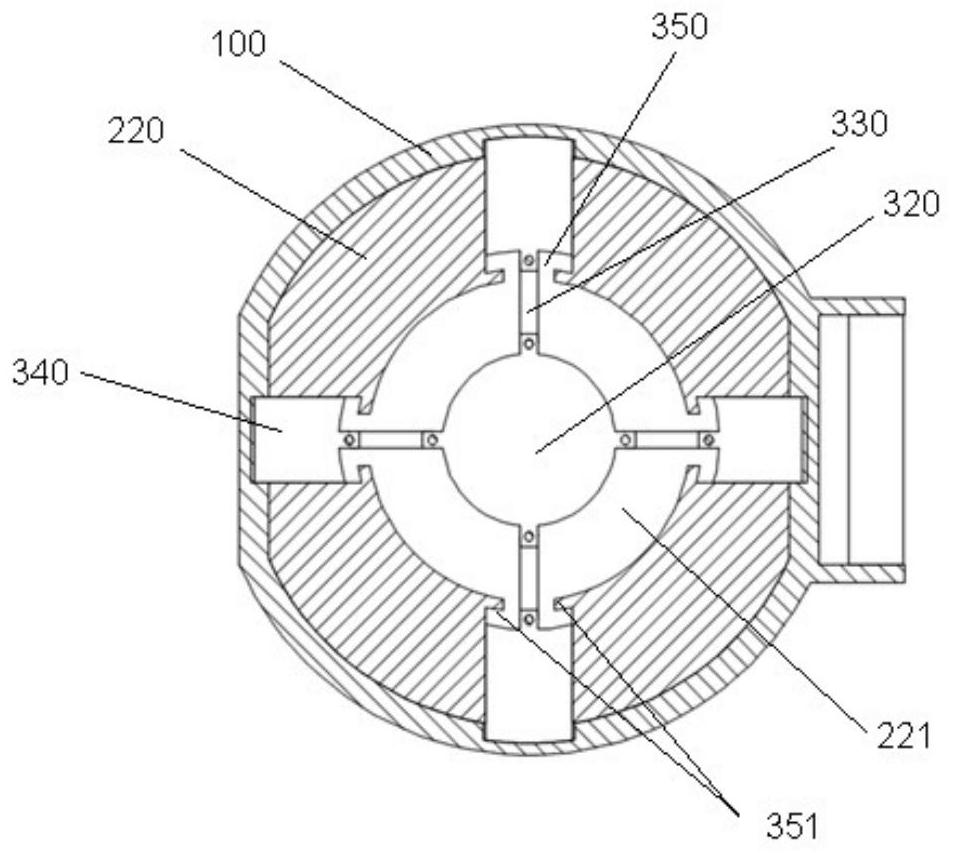

[0038] There is a cavity 221 in the middle of the cover 220, four pin holes 350 ar...

Embodiment 2

[0049] This embodiment is different from the first embodiment in that the socket and the locking pin are the socket 360 in this embodiment is through. Such as Figure 5 As shown, the insertion hole 360 penetrates the side wall of the can body 100, and when the locking pin 340 is completely inserted into the insertion hole 360, it protrudes out of the side wall of the can body 100, and the locking pin 340 is stuck on the entire side of the can body 100. On the wall, in the locked state, the tank cover 200 and the tank body 100 are more closely combined, so that the closed explosion-proof tank has a stronger ability to suppress and weaken the shock wave generated at the moment of explosion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com