Sheet hardware cutting device for hardware electromechanical

A technology for cutting devices and hardware, applied in positioning devices, driving devices, feeding devices, etc., can solve the problems of flying dust, unable to fix hardware, etc., and achieve the effect of avoiding displacement and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

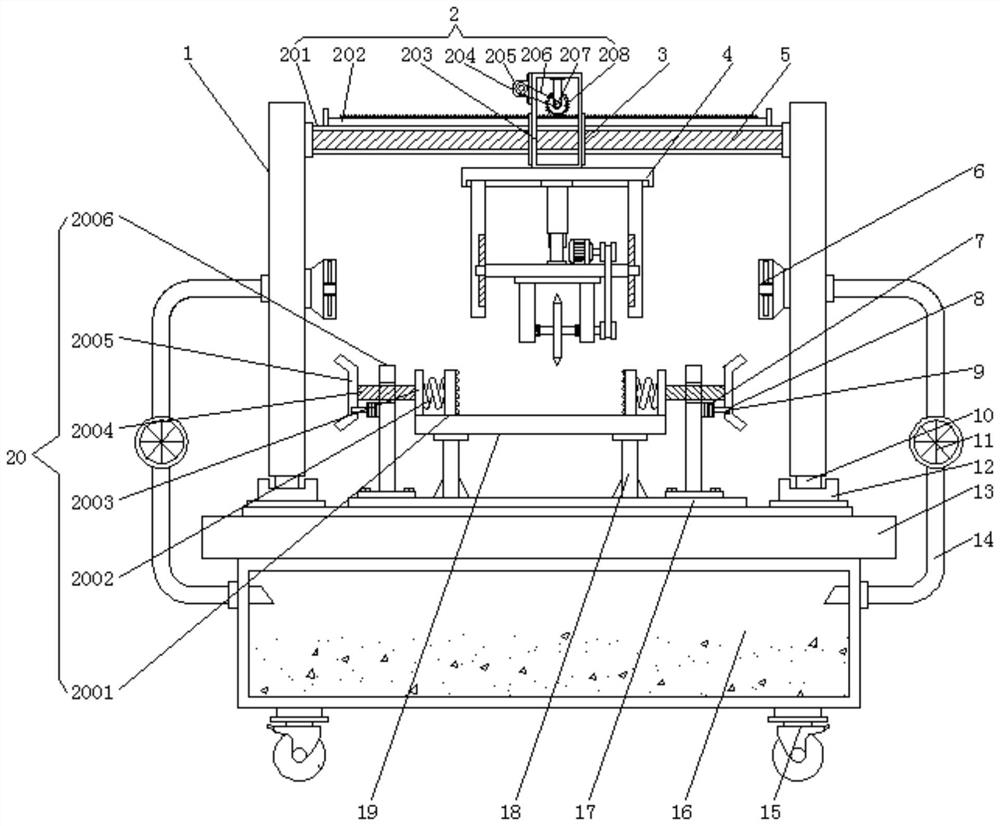

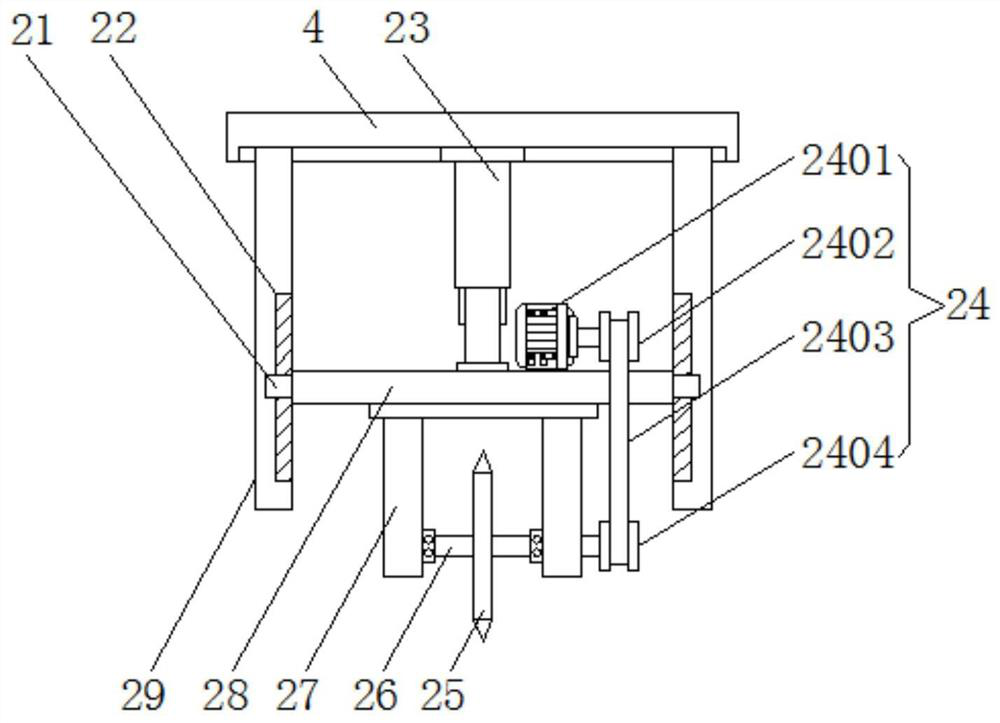

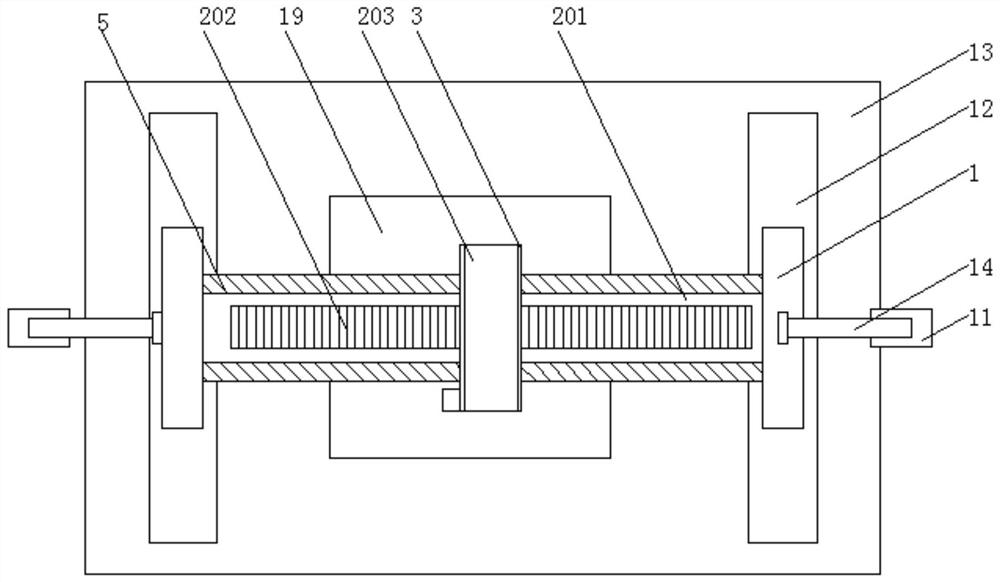

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0032] The present invention provides a technical solution: a sheet metal cutting device for hardware, electromechanical, including a box body 16, rollers 15 are installed at the four corners of the bottom of the box body 16, and a door is hinged on the front of the box body 16 through a hinge shaft Body 30, a handle 32 is installed on the front of the door body 30 away from the hinge shaft, and the center of the handle 32 is provided with a non-slip cover, which is convenient for the staff to hold the handle and open the door body 30 to clean the inside. friction between the handles to avoid hand slipping (see the accompanying drawings Figure 4 );

[0033]A control panel 31 is installed at the center of the front of the door body 30, conduits 14 are installed symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com