A cutting edge and corner device for tape measure processing

A technology of measuring tape and corners, applied in the direction of shearing devices, accessories of shearing machines, metal processing equipment, etc., can solve the problems of tediousness, safety accidents, etc., and achieve the effect of ensuring safety and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

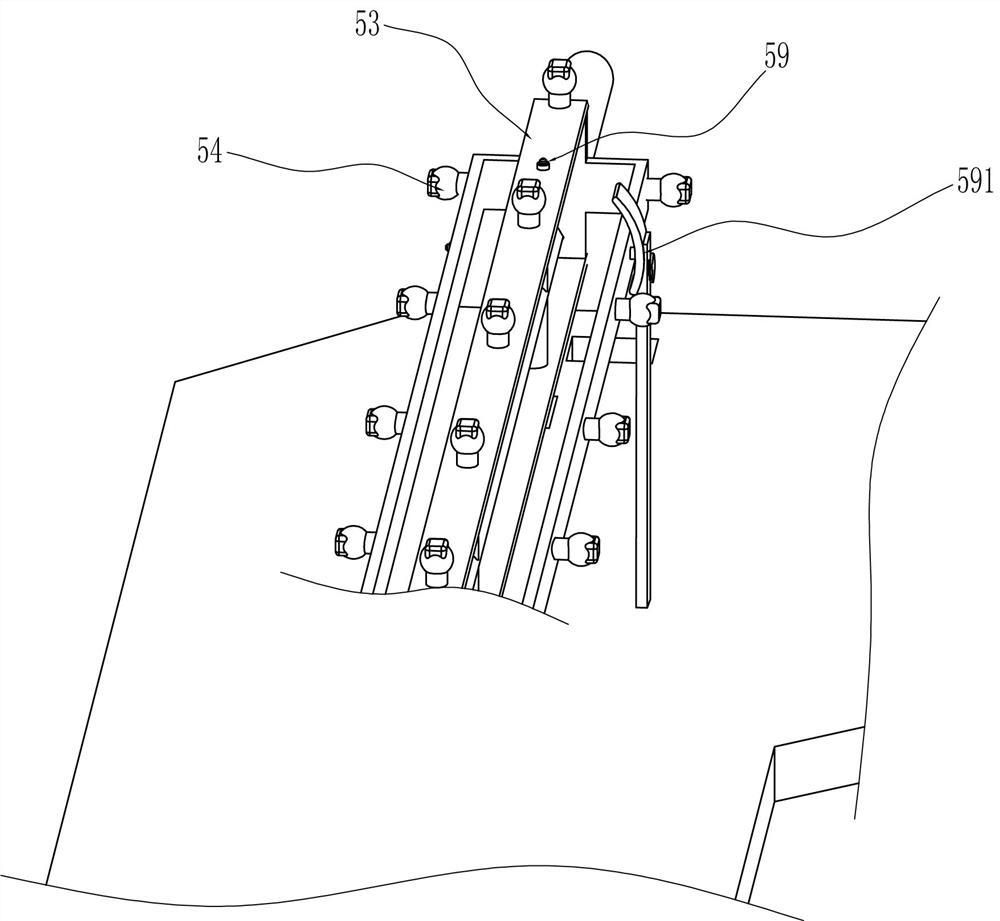

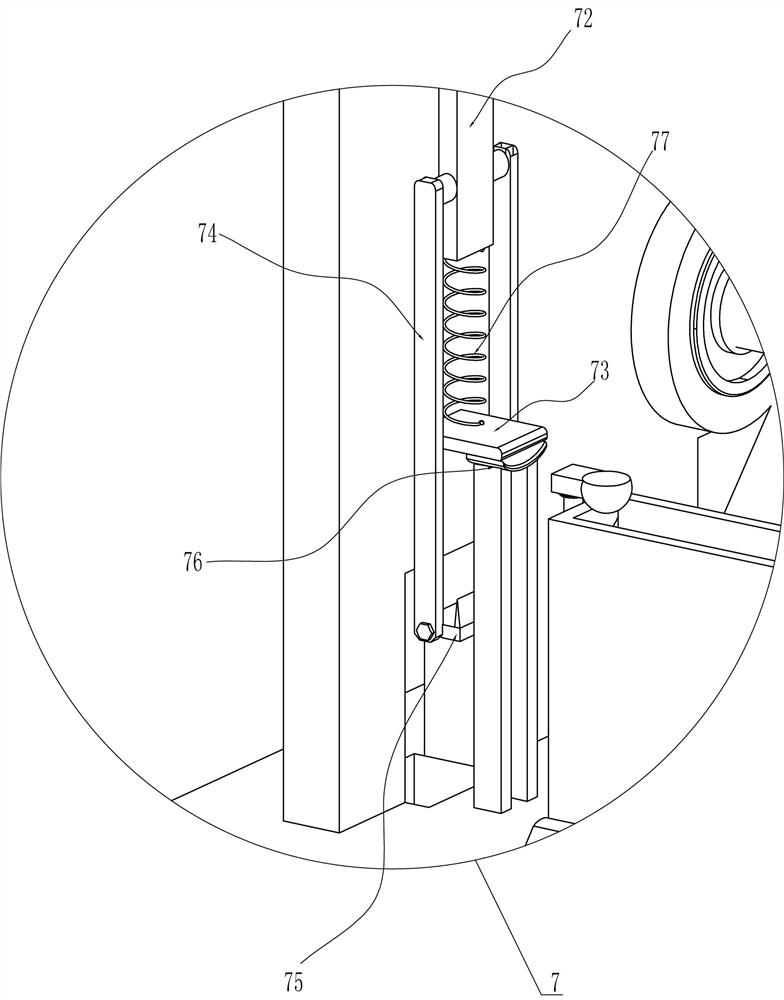

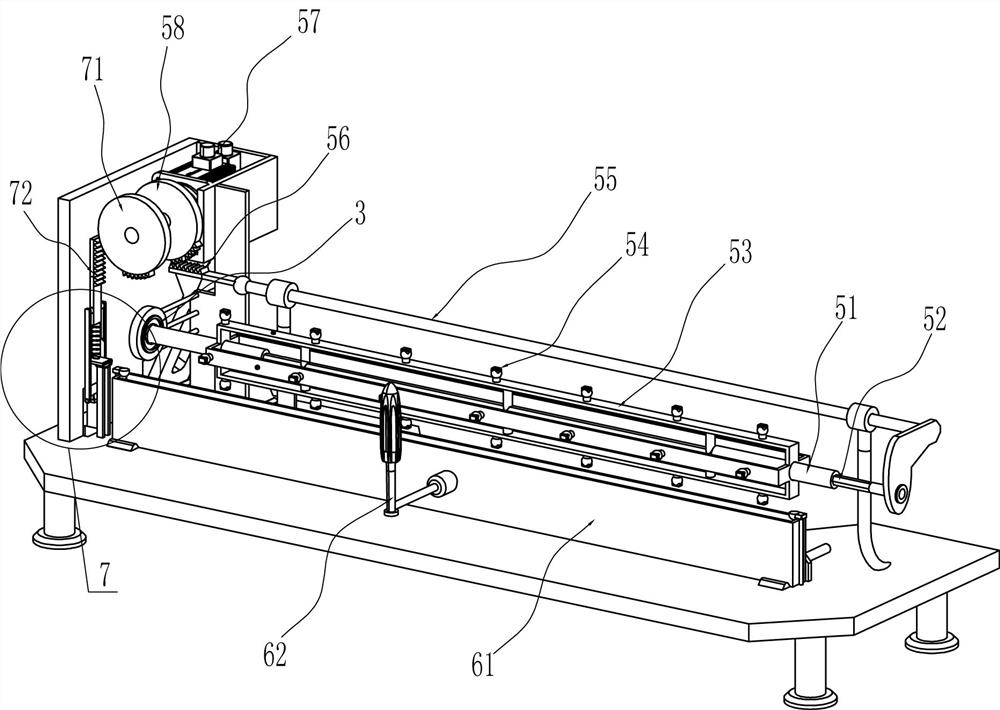

[0026] A trimming device for tape measure processing, such as Figure 1-6 As shown, it includes installation platform 1, installation frame 2, installation plate 3 and guide sleeve 4, installation frame 2 is connected to the top of installation platform 1, installation frame 2 is connected to installation platform 1 through bolts, installation frame 2 and installation platform 1 The top is connected with a mounting plate 3, the top of the mounting table 1 is connected with a guide sleeve 4 on both sides, and also includes a feeding assembly 5, a discharging assembly 6 and a cutting assembly 7, and a feeding assembly is provided between the mounting plate 3 and the mounting table 1 5. There is a discharge assembly 6 on the installation platform 1. The discharge assembly 6 is used to place the tape that needs trimming. A cutting assembly 7 is provided between the installation frame 2 and the installation platform 1.

[0027] The feeding assembly 5 includes an inner diamond-shape...

Embodiment 2

[0032] On the basis of Example 1, such as Figure 7 As shown, a rotating assembly 8 is also included. The rotating assembly 8 includes a driving gear 81, a rotating shaft 82 and a bevel gear 83. The upper part of the inner wall of the installation frame 2 is rotatably connected with a driving gear 81 that will mesh with the first sector gear 58. The installation frame 2 The lower part of the inner wall is rotatably connected with a rotating shaft 82, and the rotating shaft 82 is connected with the inner rhombic sleeve 51 with a bevel gear 83. The bevel gear 83 is used to drive the inner rhombic sleeve 51 to rotate. The drive gear 81 is in transmission connection.

[0033] When the first sector gear 58 rotates to mesh with the drive gear 81, the first sector gear 58 continues to rotate to drive the drive gear 81 to rotate, the drive gear 81 rotates the rotating shaft 82, and the rotating shaft 82 rotates through the internal rhombic sleeve 51 driven by the bevel gear 83 Rotate...

Embodiment 3

[0035] On the basis of Example 2, such as Figure 8 As shown, it also includes an arc inclined block 9, a disc 10 and a contact rod 11, and the right side of the right mounting plate 3 is connected with an arc inclined block 9, and the arc inclined block 9 is connected to the mounting plate 3 by bolts. Connected, rhombus bar 52 is connected with disc 10, and disc 10 is connected with contact rod 11, and contact rod 11 is connected with disc 10 by the mode of welding connection, and contact rod 11 cooperates with arc oblique block 9.

[0036] When the diamond-shaped rod 52 moves toward the installation frame 2, it drives the disc 10 to move toward the installation plate 3. When the rhombus rod 52 moves to the extreme, the contact rod 11 contacts the arc-shaped inclined block 9. When the rotating assembly 8 drives the diamond-shaped rod 52 When rotating, the rhombus rod 52 drives the disc 10 to rotate, and the disc 10 rotates to drive the contact rod 11 to rotate, and the contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com