Mechanical part drilling device

A technology for drilling equipment and mechanical accessories, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., and can solve the problems of no drill locking mechanism and no tool change mechanism, etc., to achieve improved Drilling efficiency and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

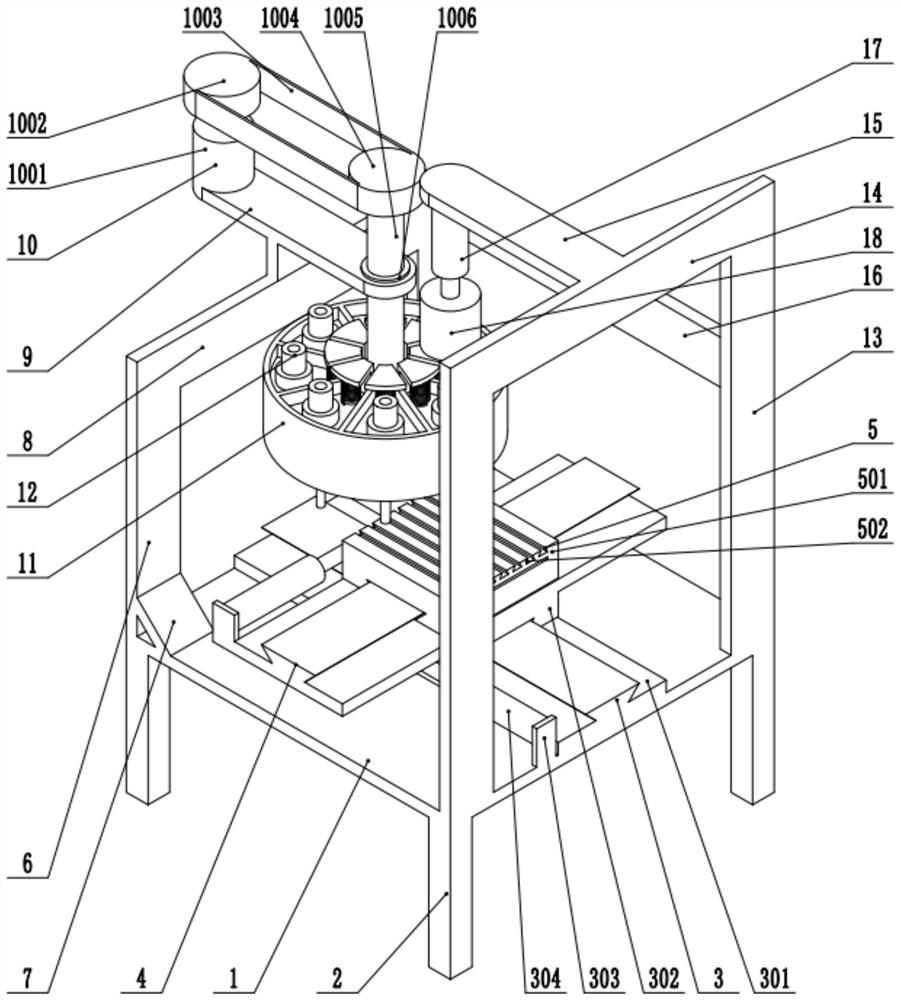

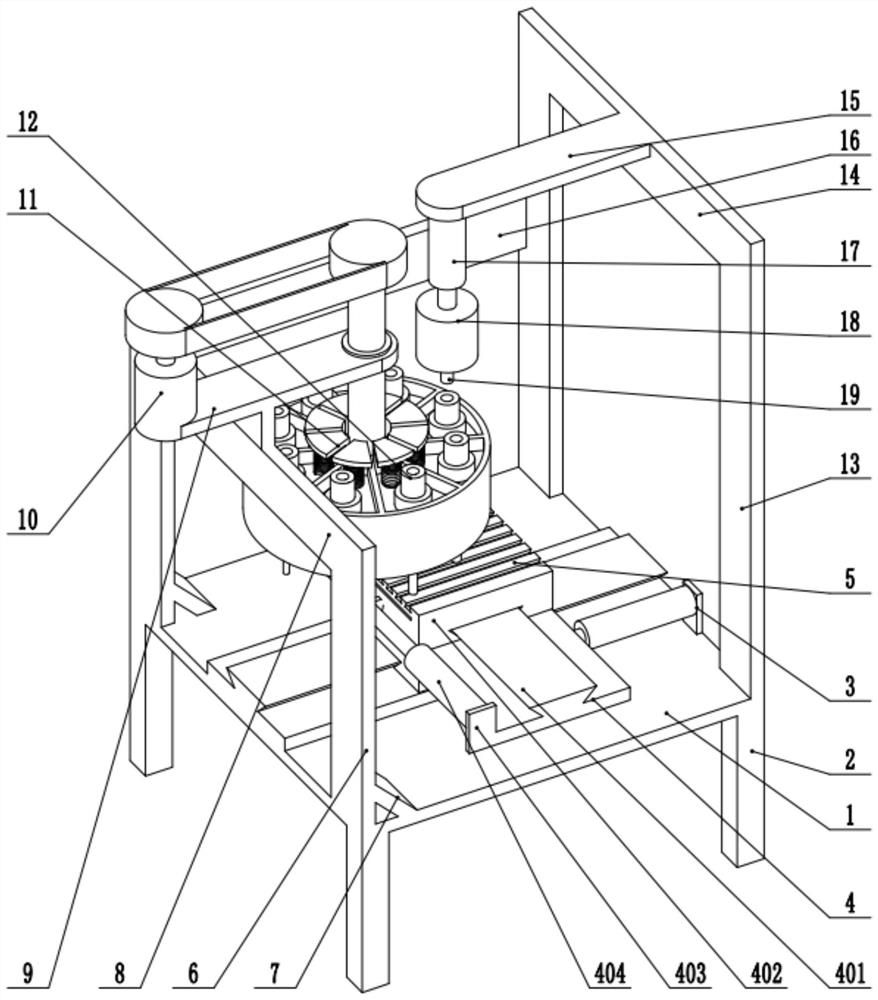

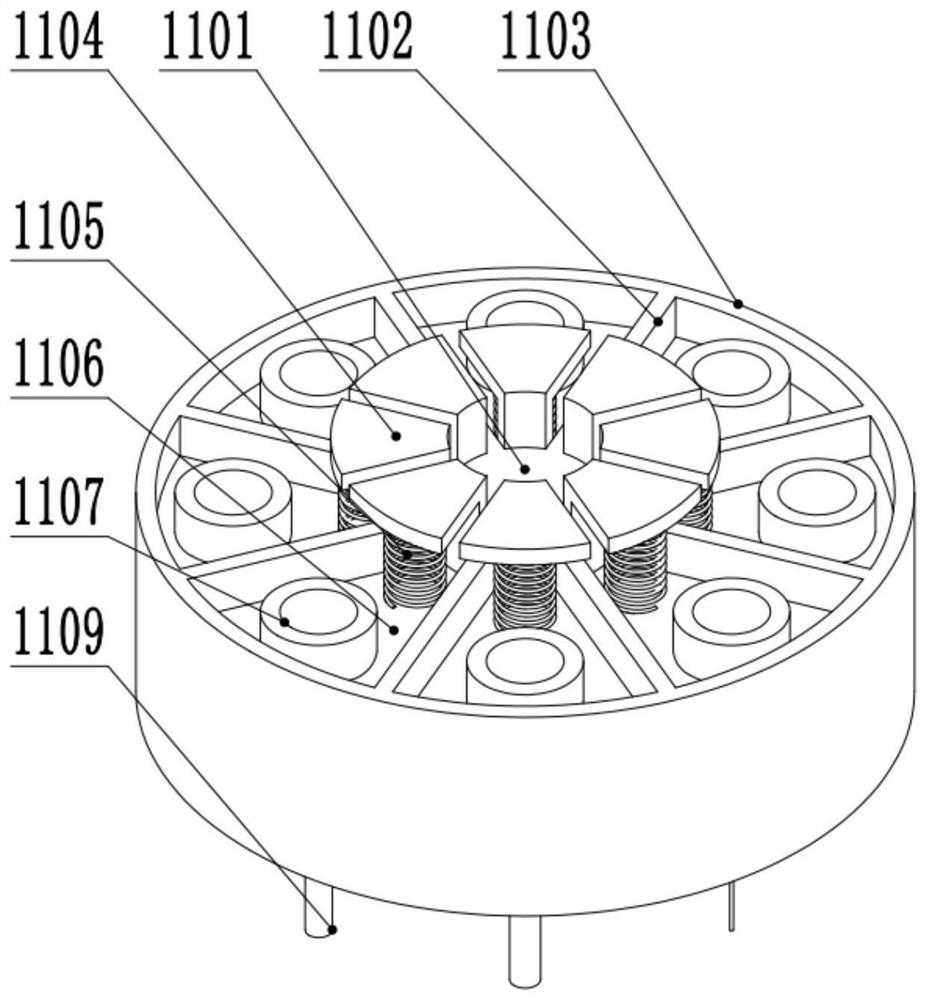

[0026] see Figure 1-6 , drilling equipment for mechanical accessories, including a base 1, the lower surface of the base 1 is fixedly connected to four support legs 2, the upper surface of the base 1 is fixedly connected to a transverse feed mechanism 3, and the upper surface of the transverse feed mechanism 3 is fixedly connected to a longitudinal feed mechanism 4. The upper surface of the longitudinal feed mechanism 4 is fixedly connected to the clamping seat 5, the upper surface of the base 1 is fixedly connected to two left vertical plates 6, the upper part of the left vertical plate 6 is fixedly connected to the left horizontal plate 8, and the left horizontal plate 8 is fixedly connected to the left vertical plate 8. Mounting seat 9, the upper surface of the left mounting seat 9 is fixedly connected to the tool changing mechanism 10, the lower part of the tool changing mechanism 10 is fixedly connected to the cutterhead 11, the upper part of the cutterhead 11 is fixedly ...

Embodiment 2

[0035] see Figure 1-6 , the other content of this embodiment is the same as that of Embodiment 1, except that: the right side of the left vertical bar 6 is fixedly connected to the support plate 7, the support plate 7 is fixedly connected to the base 1, and the left vertical plate 6 and the right vertical plate 13 The connection plate 16 is fixedly connected between them.

[0036] In the implementation process of the present invention, firstly, the mechanical parts are fixed on the clamping and fixing base 5. At this time, the horizontal feed mechanism 3 and the longitudinal feed mechanism 4 are adjusted to move the position where the mechanical parts need to be drilled to directly below the drill bit 1109. At this time, select a suitable drill bit according to the size of the hole to be drilled, that is, turn on the servo motor 1001 to drive the tool change shaft 1005 to rotate, and at this time drive the cutter head 11 to rotate. Right below, at this time, the first electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com