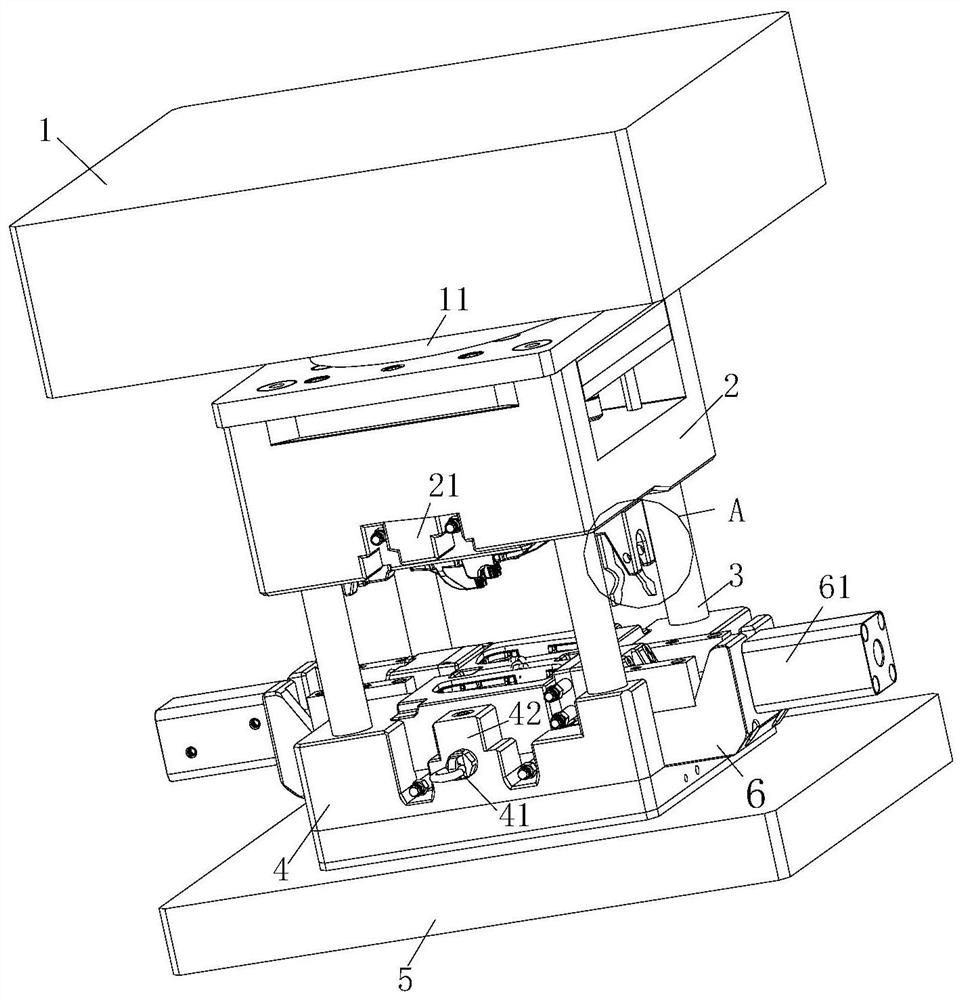

Automatic mold opening and closing mechanism

An automatic mold, mold opening and closing technology, applied in the mold field, can solve the problem of high energy consumption of the mold clamping device, achieve the effects of reducing energy consumption, accelerating separation, and avoiding bending damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

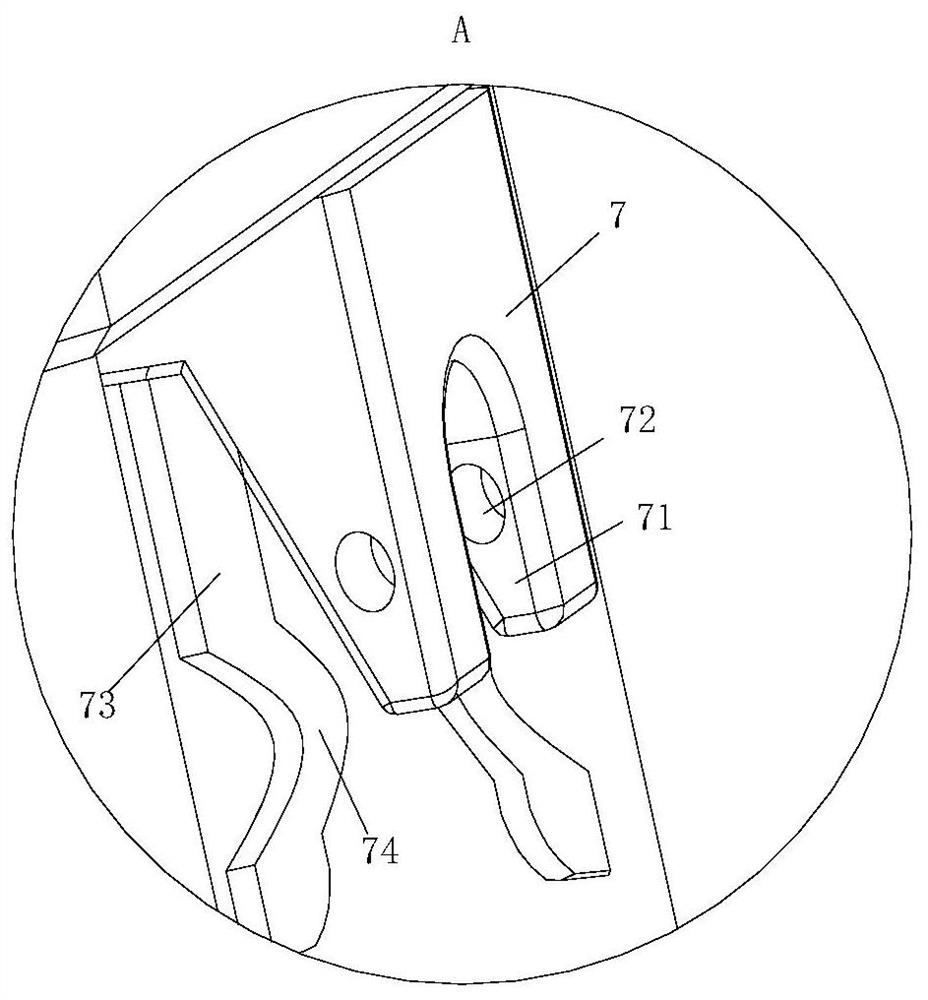

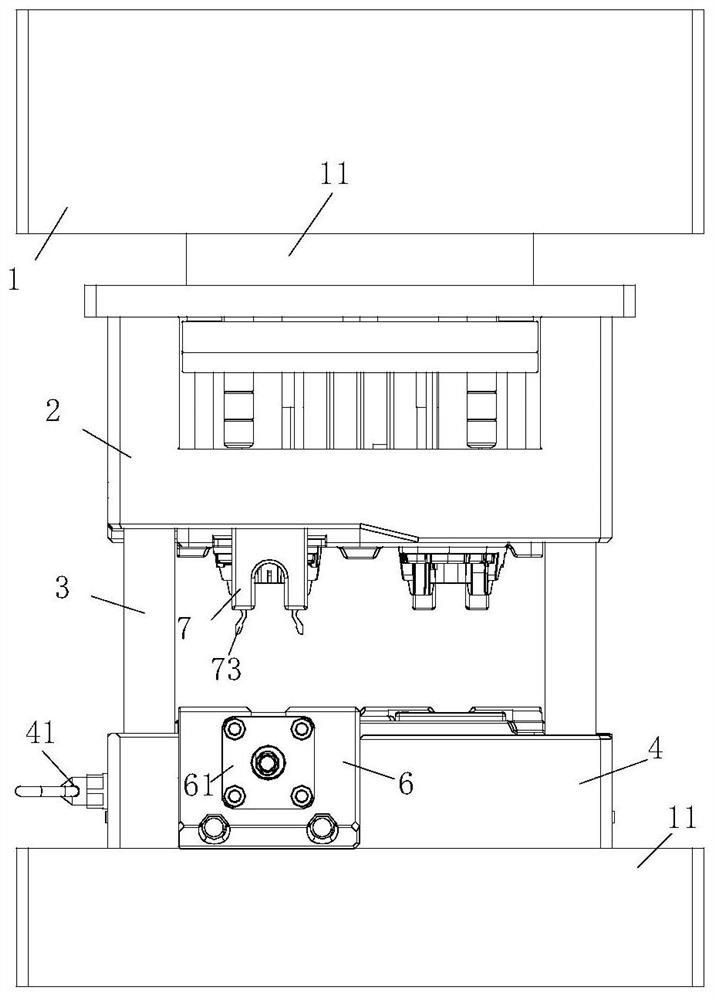

Examples

Embodiment approach

[0031] As an embodiment of the present invention, the front and rear sides of the lower mold 4 are fixedly provided with permanent magnetic chucks 41, and the front end of the permanent magnetic chuck 41 is provided with a suction cup handle 42 for controlling its holding or release. The iron block 21 matching the permanent magnetic chuck 41 is provided on the side wall of the upper mold 2 directly above the 41 . Since the elastic member 73 and the stop block 65 are clamped, their self-locking force is relatively limited, and still requires a lot of energy consumption for mold clamping. Therefore, in the process of mold closing, through the force of the permanent magnetic chuck 41 and the iron block 21 The setting can make the permanent magnetic chuck 41 suck the iron block 21 by pulling the suction cup handle 42 after the mold closing is completed, and reduce the energy consumption of the mold clamping by magnetic force; when the mold is opened, pull the suction cup handle 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com