How to make a multilayer circuit board

A technology for multilayer circuit boards and manufacturing methods, which is applied in the directions of multilayer circuit manufacturing, printed circuit manufacturing, and printed circuits, and can solve the problems of multilayer board manufacturing, warping of finished boards, board thickness or plating thickness-to-diameter ratio capabilities Restrictions and other issues to achieve the effect of shortening the production cycle and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

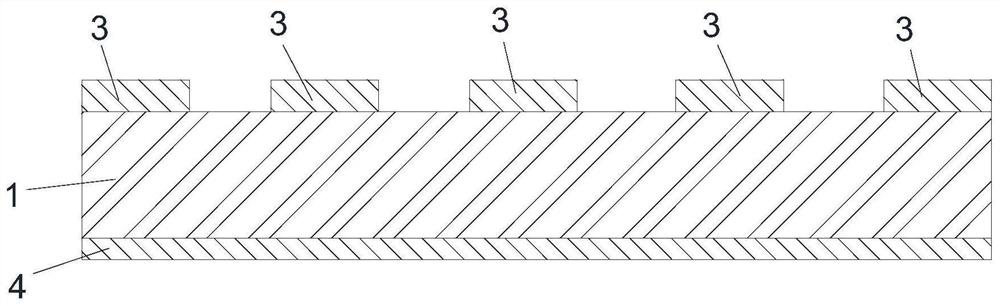

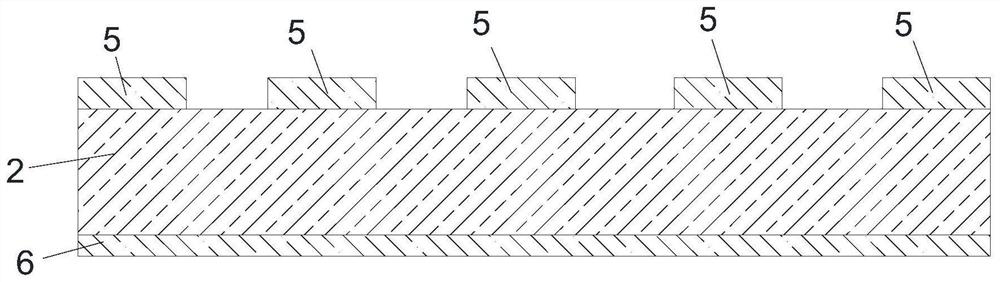

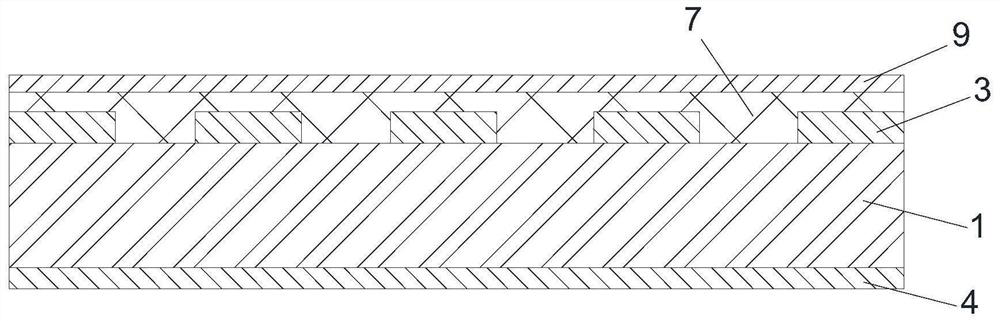

[0039] like Figure 1 to Figure 9 As shown, the method for fabricating a multilayer circuit board in this embodiment, this embodiment illustrates that a multi-layer circuit board with an asymmetric structure can be fabricated using the method of the present invention. First, the target multilayer circuit board is divided into two sub-boards, and the two sub-boards are mutually asymmetrical structures, for example, such as figure 1 As shown, the first sub-board 1 is an arbitrary layer interconnect structure, such as figure 2 As shown, the second sub-board 2 is a through-hole interconnection structure. The first sub-board 1 and the second sub-board 2 are each of symmetrical structure, and the first sub-board 1 and the second sub-board 2 are respectively fabricated according to conventional methods. The first sub-board 1 is formed with an A-side graphic layer 3 . The second sub-board 2 is formed with a C-plane pattern layer 5 . The manufacturing method of the multilayer circ...

Embodiment 2

[0052] like Figure 10 As shown in the figure, the manufacturing method of the multilayer circuit board in this embodiment, this embodiment also illustrates that the multilayer circuit board with an asymmetric structure can be manufactured by the method of the present invention. , Take two daughter boards with different layers as an example. First, the target multi-layer circuit board is divided into two sub-boards, namely the third sub-board 13 and the fourth sub-board 14, the third sub-board 13 is a 10-layer board with any layer interconnect structure, the thickness is 2 mm, and the fourth sub-board 14 It is a 6-layer board with a through-blind via interconnect structure with a thickness of 0.5mm. The third sub-board 13 is formed with the E-plane graphic layer 15 , and the fourth sub-board 14 is formed with the F-plane graphic layer 16 . The third sub-board 13 and the fourth sub-board 14 are respectively fabricated using conventional techniques. The conduction and interco...

Embodiment 3

[0062] like Figure 11 As shown, in this embodiment, the thickness of the target multilayer circuit board is 6 mm as an example, which exceeds the capability of the equipment. Therefore, the target multilayer circuit board is divided into three sub-boards with a thickness of 2 mm that can be produced by the equipment, namely the fifth sub-board 19 , the sixth sub-board 20 and the seventh sub-board 21 . The fifth sub-board 19, the sixth sub-board 20 and the seventh sub-board 21 are respectively fabricated by conventional methods. Then, the fifth sub-board 19, the sixth sub-board 20 and the seventh sub-board 21 are connected and interconnected, and the method for conducting and interconnecting the fifth sub-board 19, the sixth sub-board 20 and the seventh sub-board 21 includes the steps:

[0063] Step 1. Referring to Example 1, the first adhesive sheet 7 , the second adhesive sheet 8 and the isolation layer 10 are sequentially arranged on the L-plane graphic layer 22 of the fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com