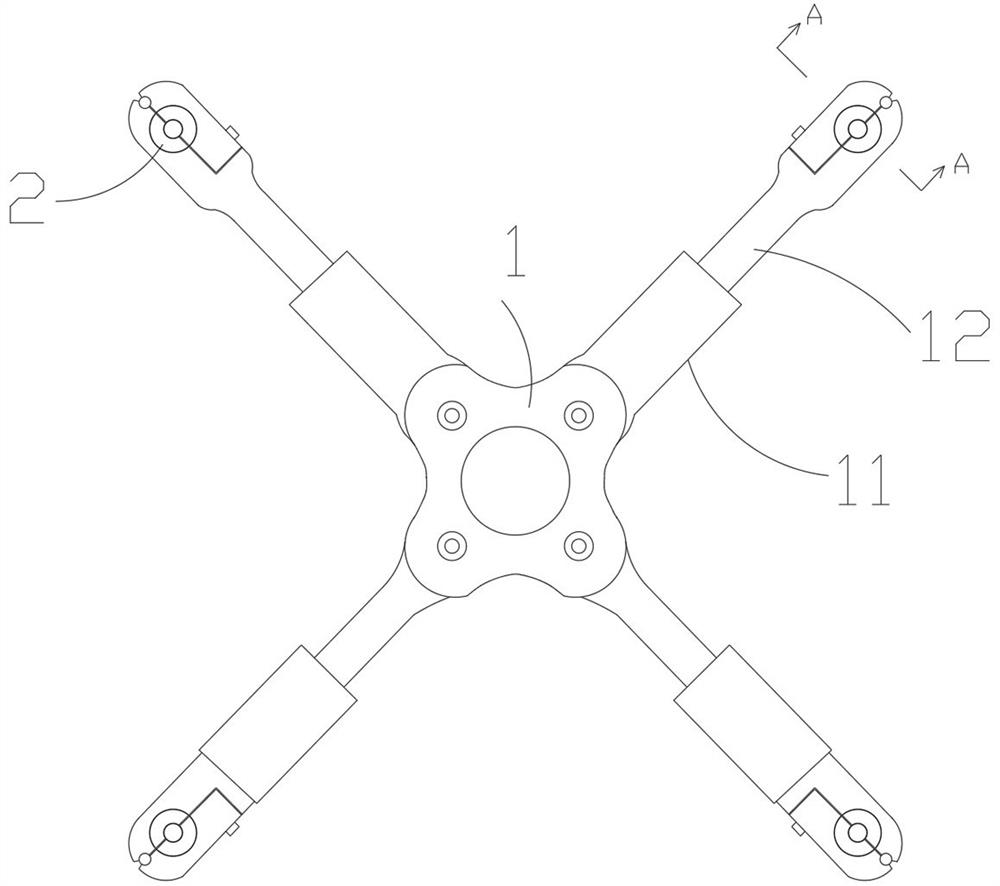

Cable spacer bar to assist in slowing down the vibration of high-altitude cables

A high-altitude cable and spacer technology, applied in cable installation, mechanical vibration damping device, overhead installation, etc., can solve the problems of small cable dancing, easy aging of rubber, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

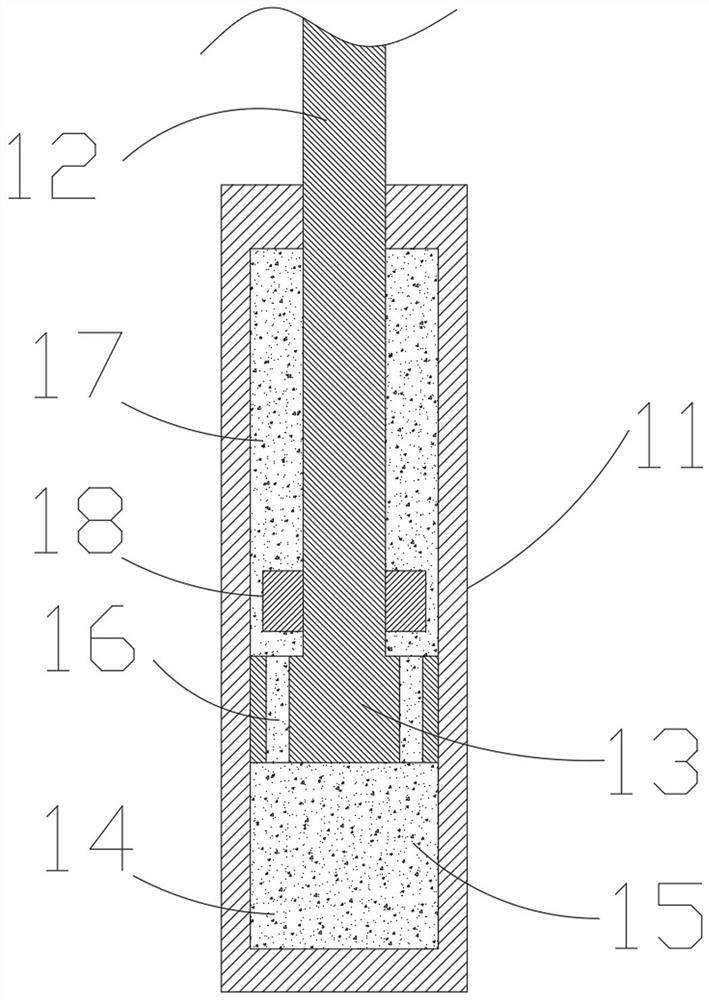

Embodiment approach 1

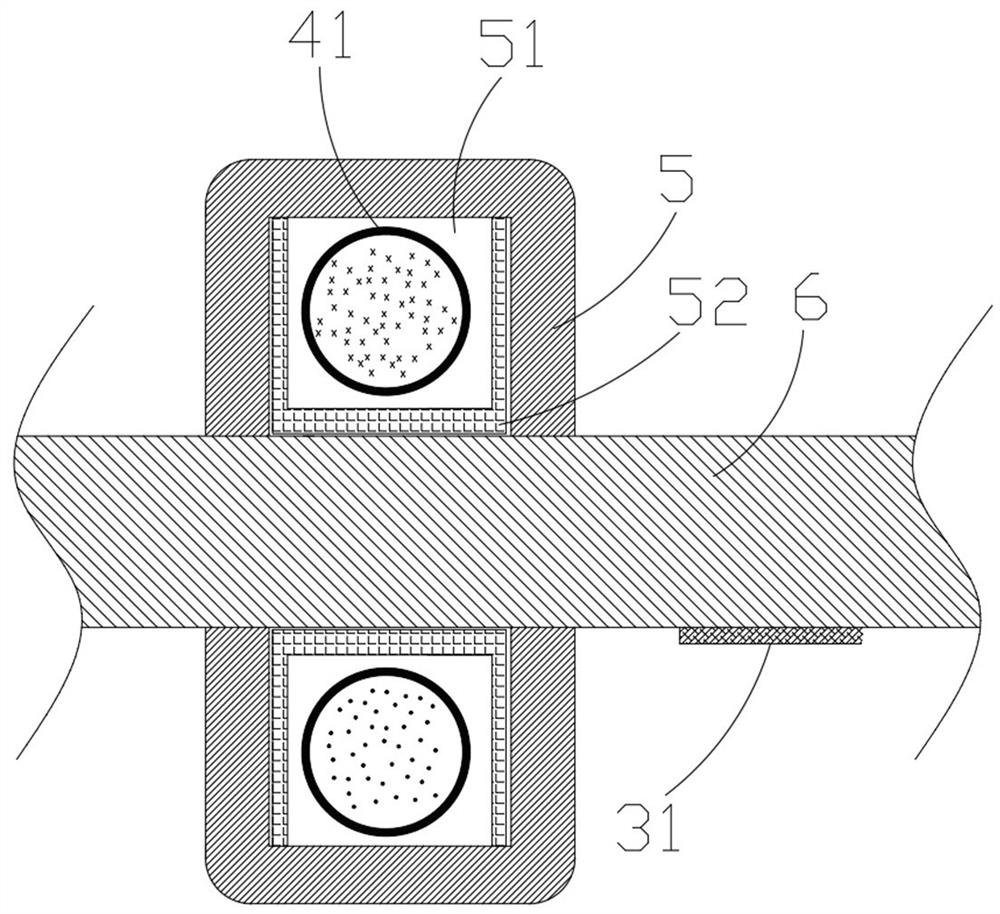

[0037]Seeimage 3 with4The inductor mechanism includes a long strip-shaped helical coil 41; the spiral coil 41 is outside the outer circumference of the high empty cable 6, which is wound along the outer circumference of the high empty cable 6, which causes the plane formed by any single linder of the spiral coil 41. The tangential direction of the high empty cable 6; the spiral coil 41 constitutes a closed loop in the power supply circuit. The structural body 5 includes two hollow half-ring parts, wherein the space portion forms a semi-annular resettlement cavity 51; the spiral coil 41 is placed at the bottom of the resettlement cavity 51, and a vertical cross section is a "concave" shaped semi-ring separating block. 52 In the resettlement chamber 51, the outer side abuts the inner end of the resettlement cavity 51, and the inside is in contact with the high-altitude cable 6.

Embodiment approach 2

[0039]SeeFigure 5 with6The inductor mechanism includes a plurality of broken annular conductor 42 disposed outside the high-altitude cable 6, along the outer circumference of the high empty cable 6; the plane formed by any annular conductor 42 is substantially toward the tangent direction of the high empty cable 6; The conductor 42 constitutes a closed loop in series with the power supply circuit, and the purpose of series is to be equal to the series circuit current, and can be effective to stabilize the sensing current, followed by the plurality of annular conductor 42 to form a whole, Improve inductance efficiency. The structural body 5 includes two hollow half-ring parts, wherein the space portion forms a semi-annular resettlement cavity 51; the spiral coil 41 is placed at the bottom of the resettlement cavity 51, and a vertical cross section is a "concave" shaped semi-ring separating block. 52 Inside the resettlement chamber 51, the outer side is inserted in the inner end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com