Efficient quality inspection package warehouse-out management control method for batch intelligent labels

A smart label, management and control technology, applied in the fields of collaborative operation devices, electromagnetic radiation induction, instruments, etc., can solve the problem that cannot be used as a smart label counting structure, cannot be directly applied to quality inspection management, and cannot solve the problem of batch intelligent label quality inspection and packaging. Warehouse management and other issues, to achieve the effect of short-distance reliable communication, convenient quality inspection and packaging management, and increase the convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

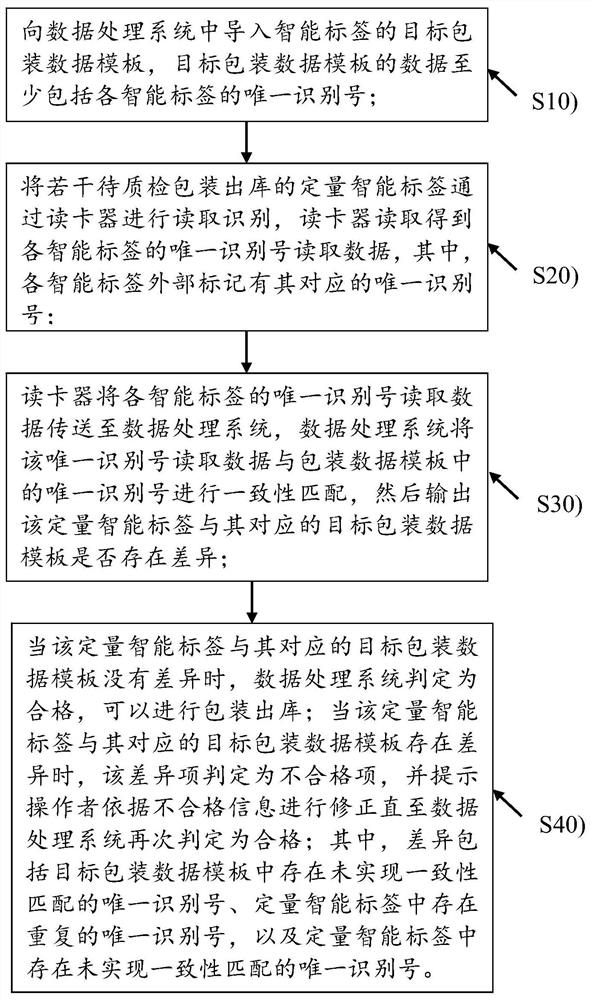

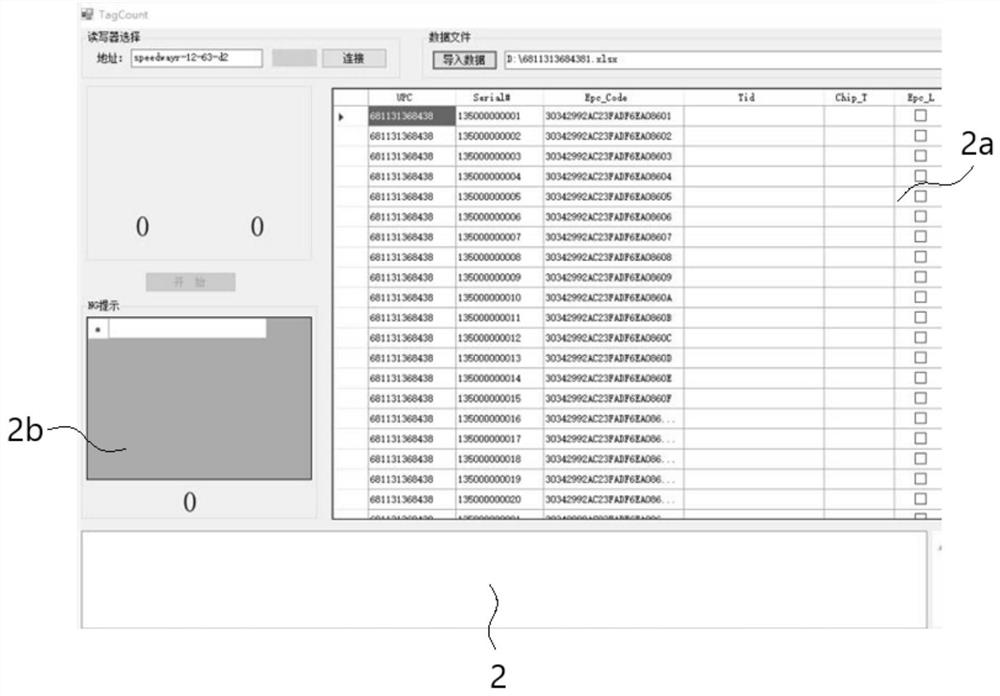

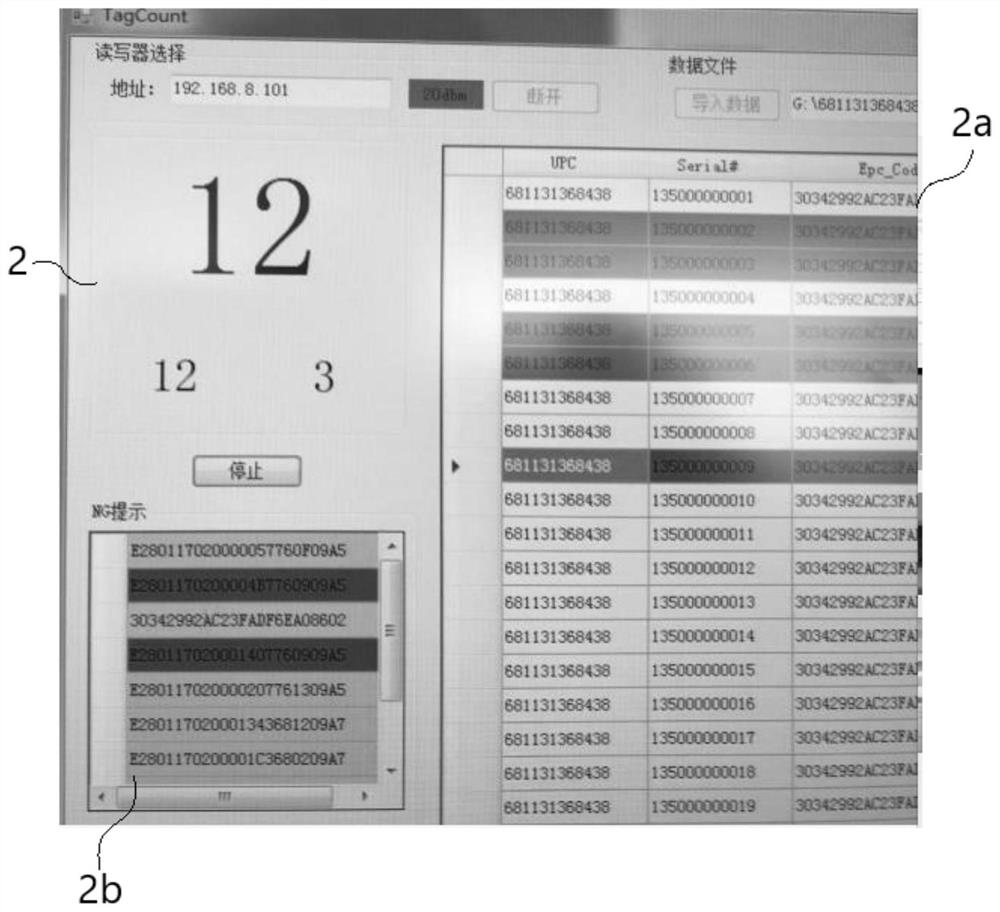

[0036] The embodiment of the present invention discloses a management and control method for high-efficiency quality inspection and packaging of batch smart labels. The operation steps include: S10), importing the target packaging data template of the smart label into the data processing system, and the data of the target packaging data template Including at least the unique identification number of each smart label; S20), read and identify a number of quantitative smart labels to be packed out of the warehouse through a card reader, and the card reader reads the unique identification number of each smart label to read data , wherein each smart label is externally marked with its corresponding unique identification number; S30), the card reader transmits the reading data of the unique identification number of each smart label to the data processing system, and the data processing system reads the data of the unique identification number Perform consistent matching with the uniq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com