Loose joint device for screw-thread-free pipeline

A technology for pipes and unions, applied in the direction of pipes/pipe joints/fittings, flange connections, sleeve/socket connections, etc. It can solve problems such as unsealable, low pressure resistance, and difficulty in threading, and achieve enhanced sealing ability, the effect of enhancing the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

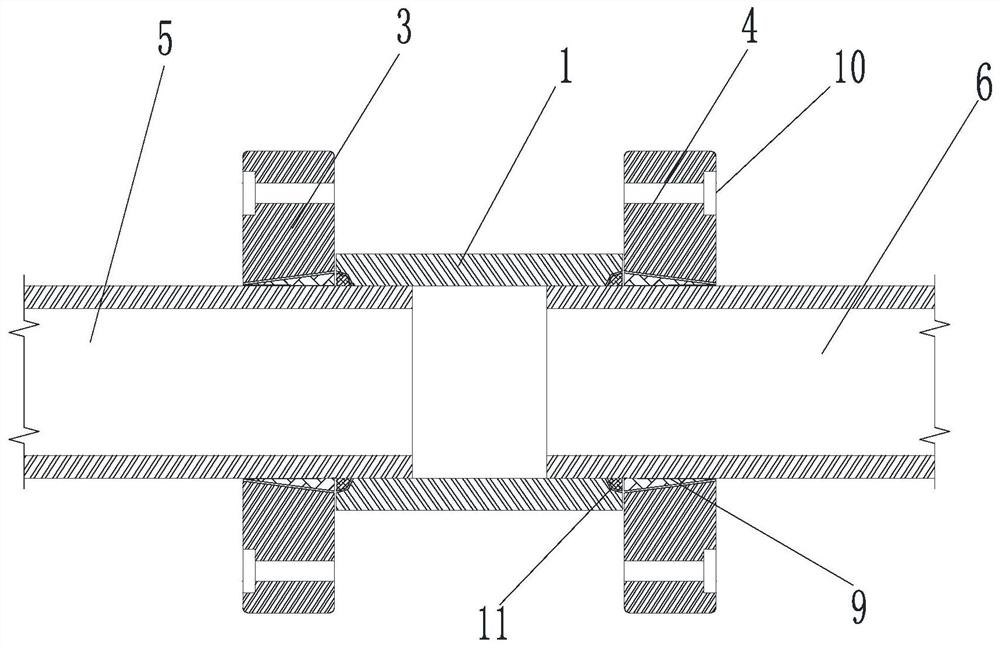

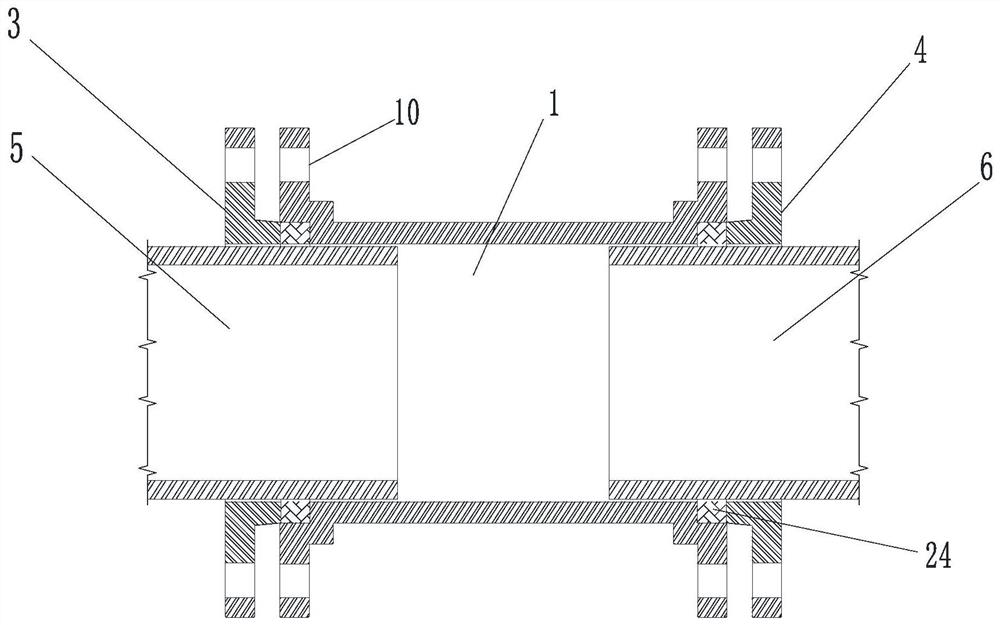

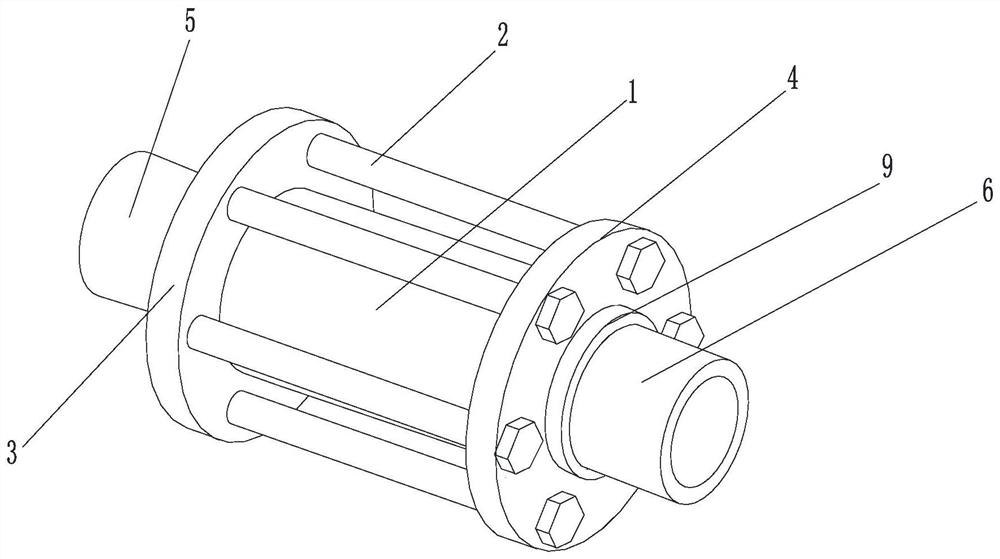

[0034] The following will combine Figure 1-14 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0035] A threaded pipe joint device for connecting the first pipe 5 and the second pipe 6 is characterized in that it comprises a first locking flange 3, a second locking flange 4, a sealing pipe 1, a locking Screw 2 and tightening mechanism, a sealing tube 1 is sandwiched between the first locking flange 3 and the second locking flange 4, the tightening mechanism includes a tightening member and a sealing member, the first locking There are fasteners between the flange 3 and the first pipe 5, the second locking flange 4 and the second pipe 6, the sealing pipe 1 and the first locking flange 3, the second locking flange 4 There are seals at the compaction place, the locking screw 2 penetrates the first locking flange 3 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com