A decorative coating for stainless steel substrates

A stainless steel, decorative technology, applied in the direction of metal material coating process, coating, vacuum evaporation plating, etc., can solve problems such as poor flexibility, and achieve the effect of flexible design, high flexibility, and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

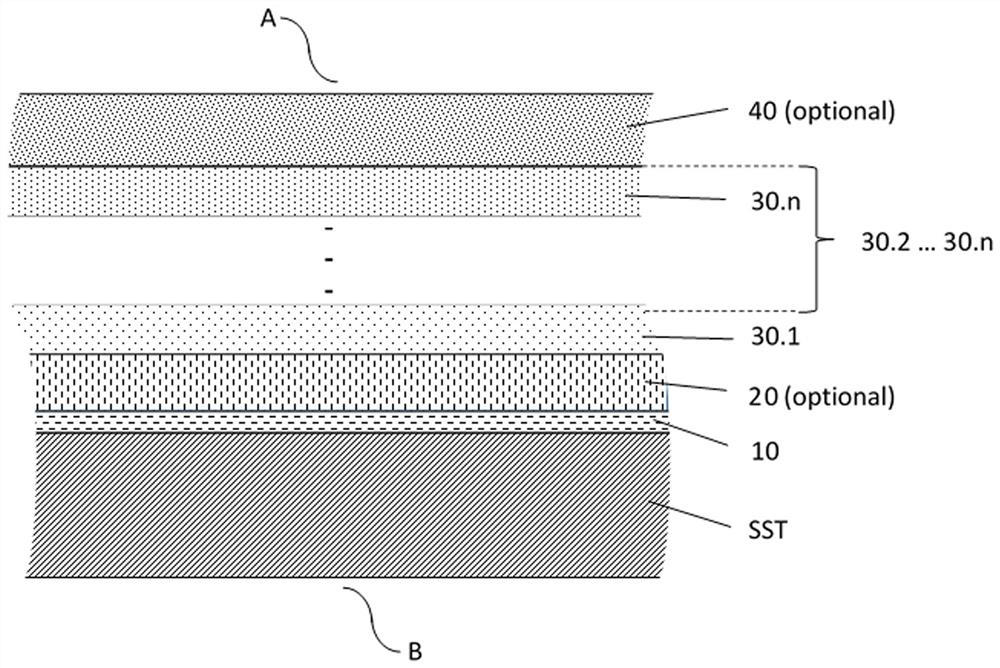

[0027] The specific embodiment of the present invention will be described below with reference to accompanying drawing 1. For a comprehensive understanding of the present invention, the following descriptions will

[0028] A schematic diagram of the coating system contemplated by the present invention is provided in FIG. 1 . The coating system consists of strips or plates

[0029] An adhesion layer (10) consisting of metallic chromium Cr above the coating surface A of the stainless steel substrate (SST). directly on stainless

[0030] The first compound coating (30.1) can be plated over the adhesion layer (10), but can also be plated directly on the stainless steel base

[0031] A further compound coating (30.2) may be plated over the compound coating (30.1), which may be used to describe the compound

[0032] On top of the compound film layers (30.1) and (30.2), additional compound coatings may be plated to n (30.n), where each

[0033] Additional plating may be made over the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com