Accessory surface spray coating equipment realizing uniform spray coating for automobile accessory processing

A technology for auto parts and surface spraying, which is applied in spray booths, spraying devices, etc., can solve the problems of unfavorable auto parts processing, poor spraying effect, and low spraying efficiency, so as to achieve good spraying effect, good cleaning effect, and energy saving The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

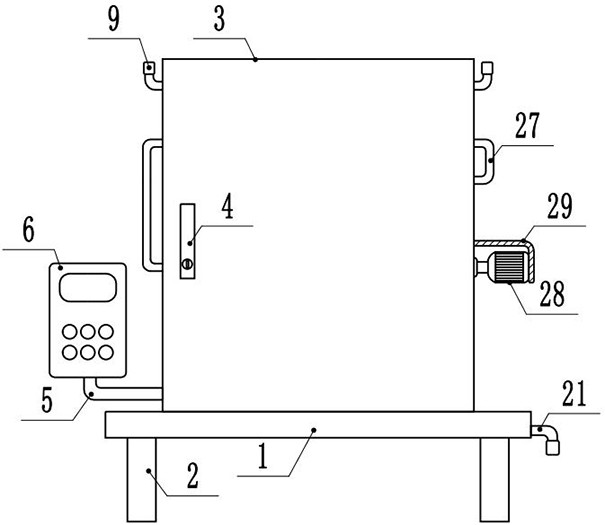

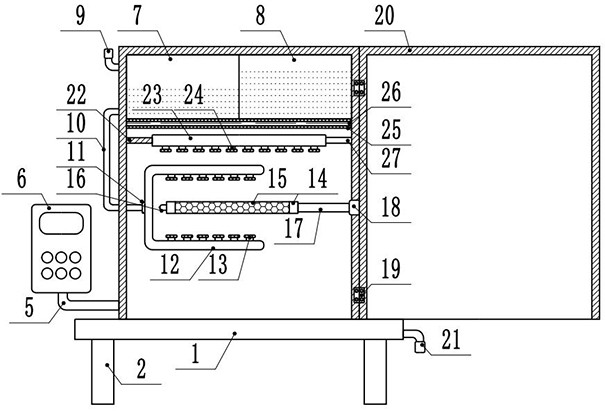

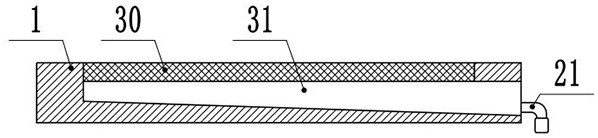

[0026] see Figure 1-5 , a kind of auto parts processing equipment with uniform spraying on the surface of parts, including a spray box 3, a fixed plate 25 is fixedly connected to the top of the left and right inner walls of the spray box 3, the fixed plate 25 has a mesh-like air-permeable structure, and the inside of the fixed plate 25 A drying device 26 is fixedly installed, and a spraying liquid tank 7 and a cleaning liquid tank 8 are respectively placed on the left and right sides above the fixed plate 25, and the two sides of the spraying liquid tank 7 and the cleaning liquid tank 8 are connected with liquid replenishing pipes 9 respectively.

[0027] And, the lower left side of the spraying liquid tank 7 is fixedly connected with a connecting pipe 10, and the other end of the connecting pipe 10 passes through the inside of the left side of the spraying tank 3 and is connected with a transfer pipeline 11 in rotation, and the other end of the transfer pipeline 11 Spraying ...

Embodiment 2

[0030] see Figure 1-5 , a kind of auto parts processing equipment with uniform spraying on the surface of parts, including a spray box 3, a fixed plate 25 is fixedly connected to the top of the left and right inner walls of the spray box 3, the fixed plate 25 has a mesh-like air-permeable structure, and the inside of the fixed plate 25 A drying device 26 is fixedly installed, and a spraying liquid tank 7 and a cleaning liquid tank 8 are respectively placed on the left and right sides above the fixed plate 25, and the two sides of the spraying liquid tank 7 and the cleaning liquid tank 8 are connected with liquid replenishing pipes 9 respectively.

[0031] And, the lower left side of the spraying liquid tank 7 is fixedly connected with a connecting pipe 10, and the other end of the connecting pipe 10 passes through the inside of the left side of the spraying tank 3 and is connected with a transfer pipeline 11 in rotation, and the other end of the transfer pipeline 11 Spraying ...

Embodiment 3

[0035] see Figure 1-5 , a kind of auto parts processing equipment with uniform spraying on the surface of parts, including a spray box 3, a fixed plate 25 is fixedly connected to the top of the left and right inner walls of the spray box 3, the fixed plate 25 has a mesh-like air-permeable structure, and the inside of the fixed plate 25 A drying device 26 is fixedly installed, and a spraying liquid tank 7 and a cleaning liquid tank 8 are respectively placed on the left and right sides above the fixed plate 25, and the two sides of the spraying liquid tank 7 and the cleaning liquid tank 8 are connected with liquid replenishing pipes 9 respectively.

[0036] And, the lower left side of the spraying liquid tank 7 is fixedly connected with a connecting pipe 10, and the other end of the connecting pipe 10 passes through the inside of the left side of the spraying tank 3 and is connected with a transfer pipeline 11 in rotation, and the other end of the transfer pipeline 11 Spraying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com