Shabby metal crushing and recycling equipment

A technology for recycling equipment and metals, applied in the field of broken metal crushing and recycling equipment, can solve the problems of difficult separation and recycling, low recycling rate, environmental pollution, etc., so as to improve efficiency and practicability, improve crushing efficiency and quality, and prevent metal massive stacking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

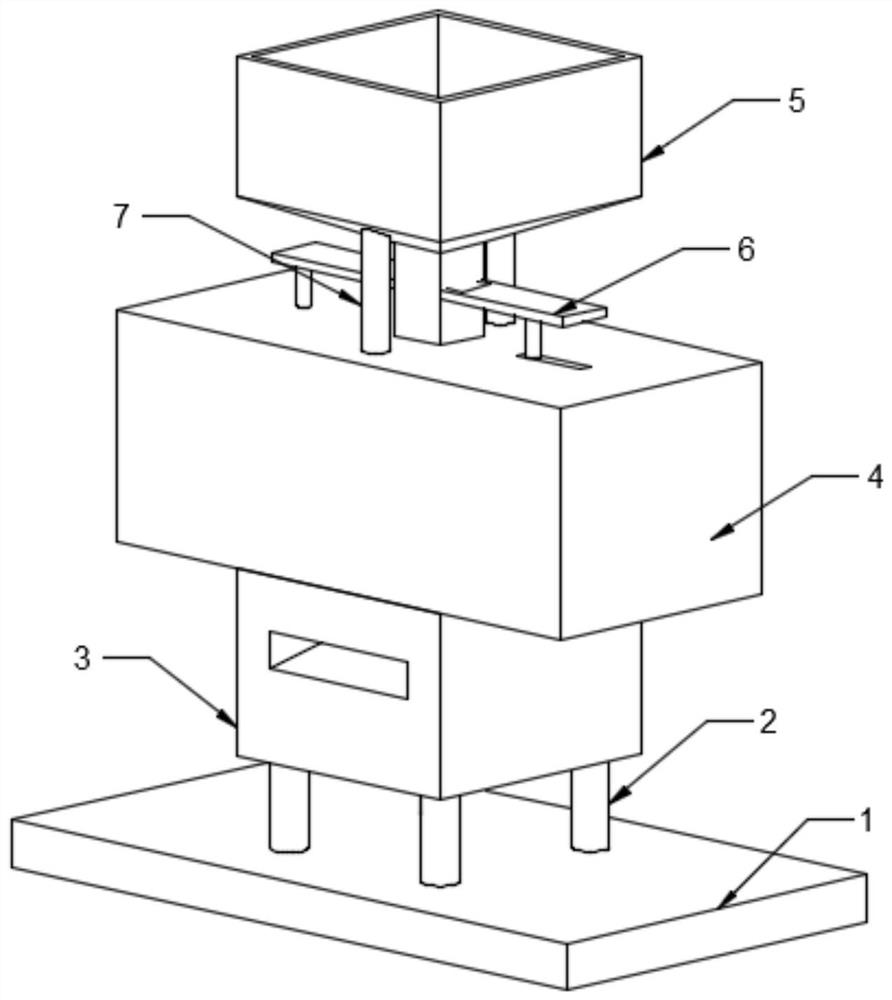

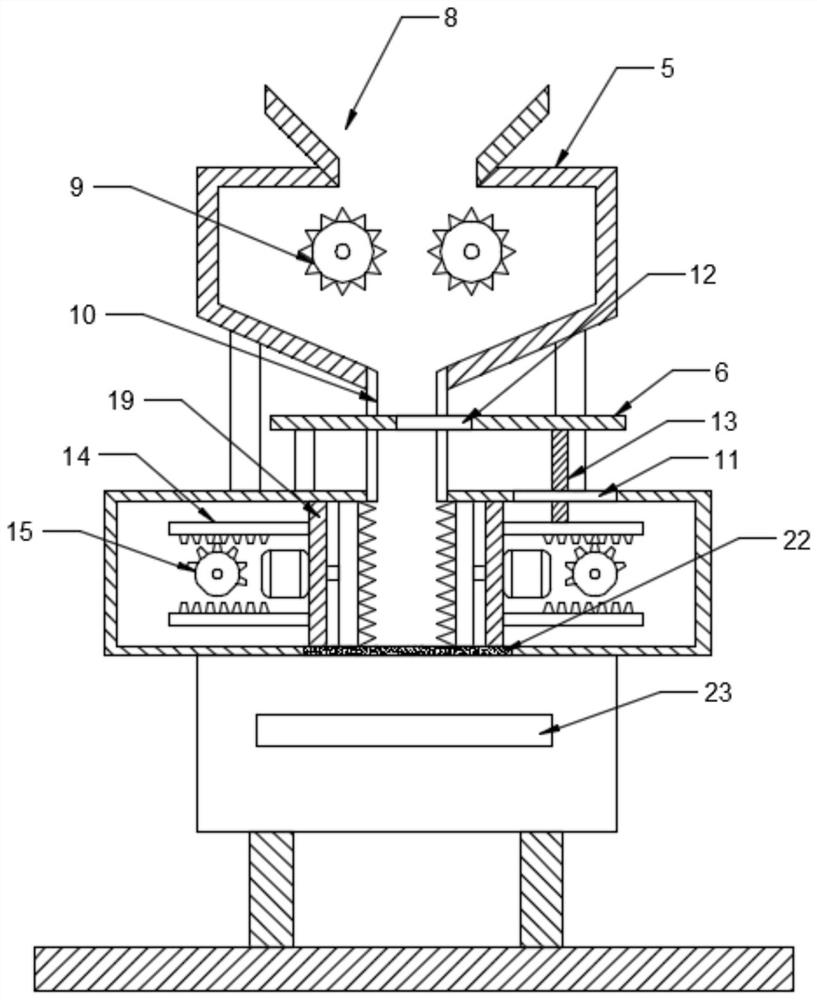

[0029] see Figure 1-5 , a broken metal recycling equipment, including a base 1, a support column 2, a screening frame 3, a crushing frame 4, a feeding frame 5, a column 7 and a blanking channel 10, and the feeding frame 5 is fixedly installed on the crushing frame through the column 7 4, the crushing frame 4 is fixed on the screening frame 3, the blanking channel 10 is connected to the feeding frame 5 and the crushing frame 4, the screening frame 3 is fixed on the base 1 through the support column 2, and the old metal pre-loading frame is arranged in the feeding frame 5. crushing assembly, the crushing frame 4 is provided with an old metal crushing assembly,

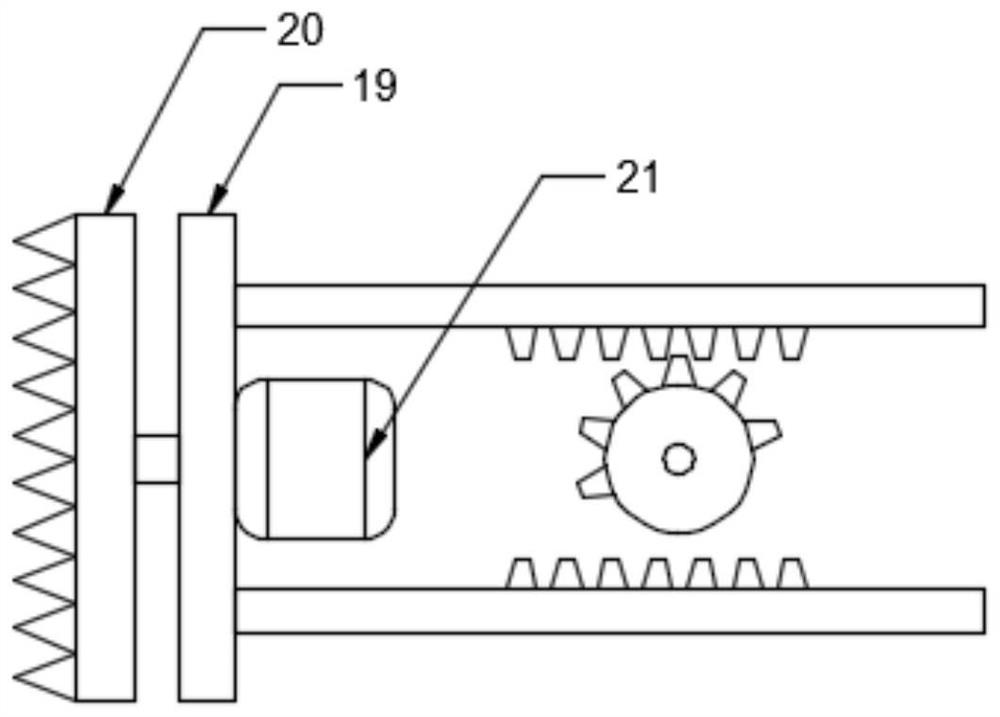

[0030] The specific type of the old metal crushing assembly is not limited. In this embodiment, preferably, the old metal crushing assembly includes a fixed plate 19, a crushing disc 20, a crushing motor 21 and a screen hole 22. The two fixed plates 19 are arranged symmetrically and slide Installed in the cylindrical c...

Embodiment 2

[0040] In order to improve the crushing quality, this embodiment is further improved on the basis of Embodiment 1. The improvement is that: the top of the screening frame 3 is provided with a through hole 26 corresponding to the sieve hole 22, and a sieve plate is arranged below the through hole 26. 27. A vibrating motor 28 is connected to the sieve plate 27. The side wall of the screening frame 3 on the lower side of the sieve plate 27 is provided with a screening outlet 23, and the bottom of the screening frame 3 is provided with a discharge port 30. The crushed metal The debris enters the screening frame 3 from the through hole 26 and gathers on the sieve plate 27. The vibrating motor 28 drives the sieve plate 27 to vibrate and screen. The thoroughly crushed metal falls and is discharged from the discharge port, and the unbroken metal is discharged from the screening outlet 23. , can be broken again.

[0041] Further, in order to facilitate the discharge of metal fragments,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com