Flat sheet membrane supporting screen plate capable of forming water outlet and circulation channels after being spliced

A technology for supporting stencils and circulation channels, applied in the field of flat membranes, can solve the problems of easy aging of hoses, time-consuming and laborious, inconvenient plugging, etc., achieve the effects of convenient and fast assembly, reduce costs, and increase water collection flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

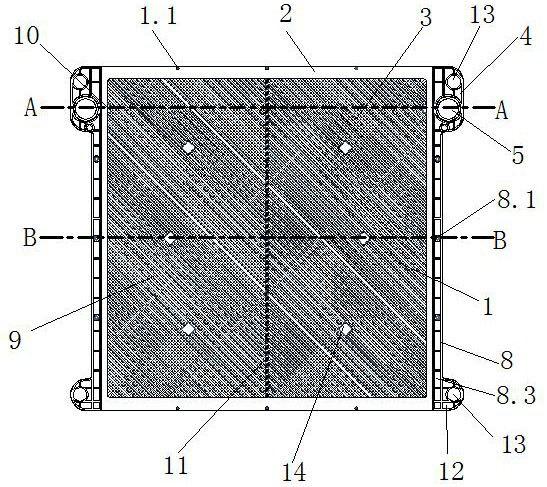

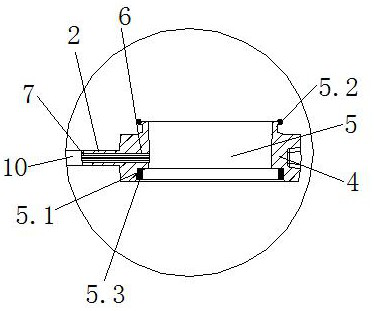

[0029] Embodiment 1: as figure 1 , 2 , 3, 4, and 5, a flat membrane support screen that can form water outlet and circulation channels after splicing, including a membrane element support plate 1, and the membrane element support plate 1 includes edge strips 2 around and located in the edge strips 2 The deflector plate 3, the two sides of the top side bar and the bottom side bar of the membrane element support plate 1 are provided with a number of No. 2 protrusions 1.1. There are several No. 1 lugs 4 at the side bar 2 of the membrane element support plate 1, and there are two No. 1 lugs 4, and the two No. 1 lugs 4 are respectively located at the side top side bars of the membrane element support plate 1. One There are several outlet pipes 5 on the number lug 4, one end of the outlet pipe 5 is provided with an annular groove 5.1, the other end is provided with an annular bump 5.2 for snapping into the annular groove 5.1, and a sealing gasket 5.3 is arranged inside the annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com