Light-emitting device and flexible filament lamp

A technology for light-emitting devices and flexible light bars, which is applied to lighting devices, components of lighting devices, semiconductor devices of light-emitting elements, etc. Automatic assembly and other problems, to achieve the effect of solving the discontinuity of light perception, reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

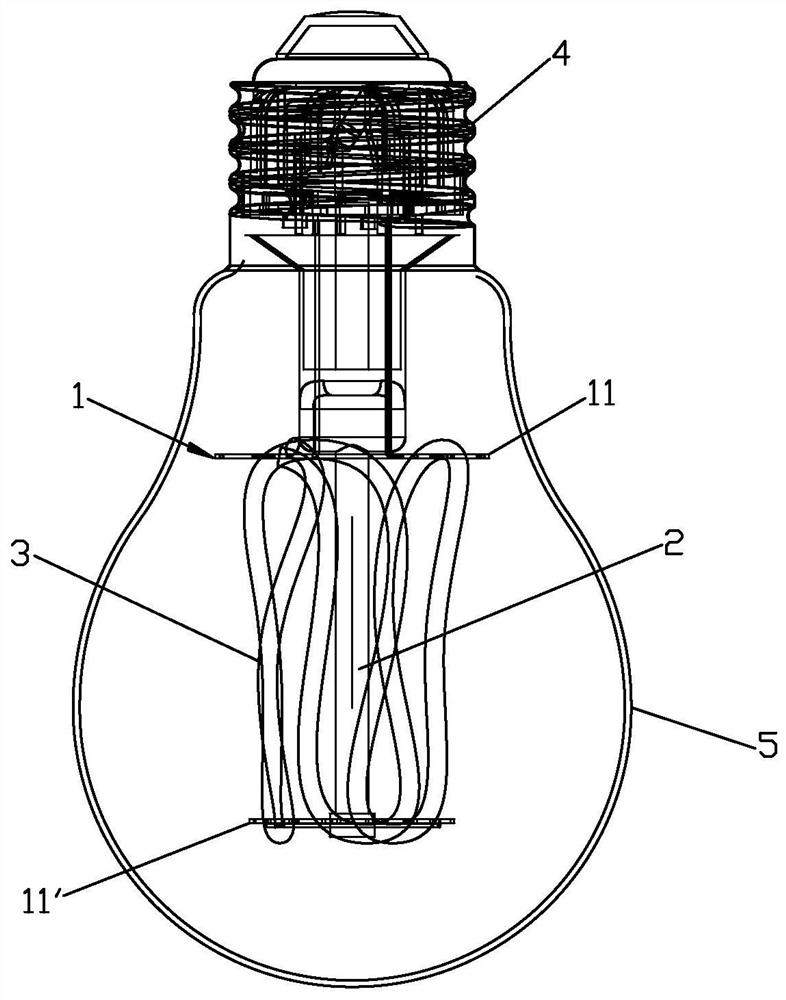

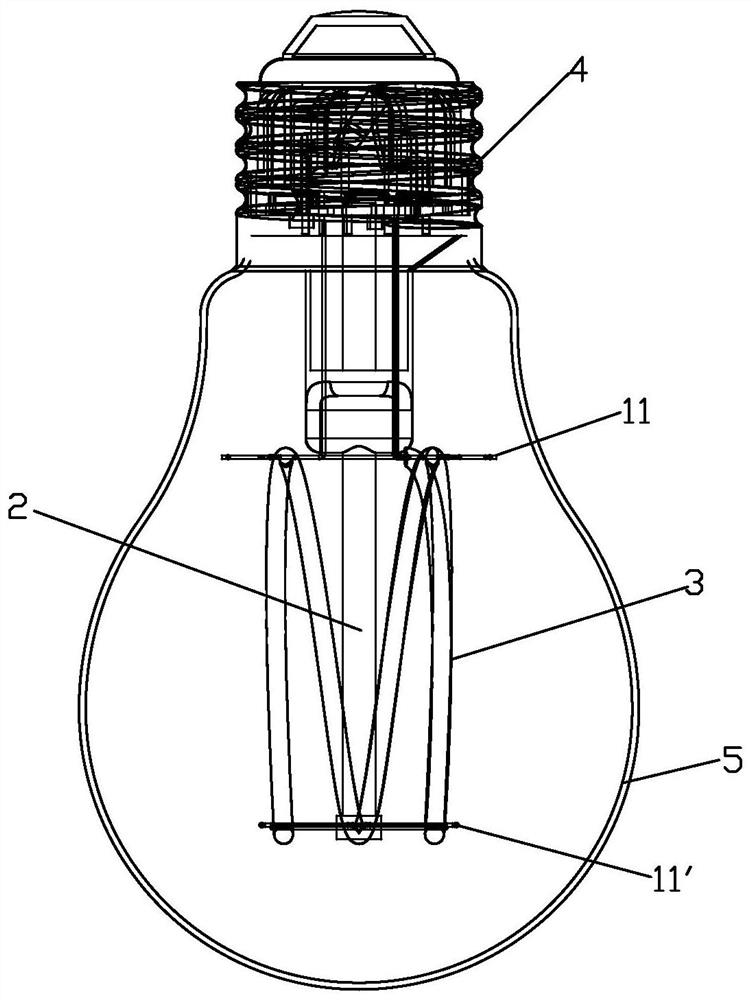

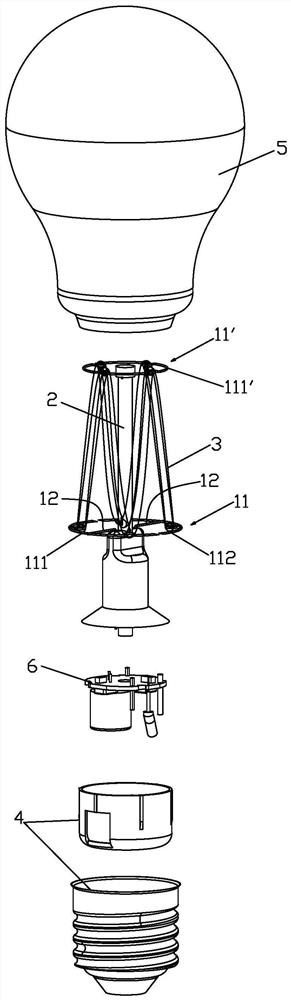

[0040] Please check Figure 1 to Figure 5 , a light emitting device comprising a support component 1 , a stem 2 supporting the support component 1 and a flexible light strip 3 . The support assembly 1 includes two surrounding frames 11, 11' sleeved outside the core column 2. The two surrounding frames 11, 11' are arranged at intervals along the core column 2 as shown in the figure. The flexible light bar 3 The two surrounding frames 11 , 11 ′ are wound alternately and cyclically at intervals to form a wavy line structure surrounding the stem 2 . The wavy line is sinusoidal or V-shaped. The flexible light bar 3 is, for example, an LED flexible light.

[0041] The two surrounding frames 11, 11' are respectively the first surrounding frame 11 and the second surrounding frame 11'. The first surrounding frame 11 includes two arc-shaped first connecting sections 111 arranged symmetrically at intervals. The two first connecting sections 111 are relatively fixedly installed on the st...

Embodiment 2

[0046] Please check Image 6 with Figure 7, it differs from Embodiment 1 in that: the first connecting section and the second connecting section are circumferentially evenly spaced and fixed with a second connecting portion convexly arranged, the second connecting portion includes a hook-shaped buckle 113, the The flexible light bar 3 is connected to the hook buckles 113 of the two surrounding frames of the support assembly 1 . The hook buckle 113 can be located on the plane of the surrounding frame 11 , or both are vertically arranged, or, the hook buckle 113 is inclined inward or outward relative to the surrounding frame 11 .

Embodiment 3

[0048] Please check Figure 8 , it differs from Embodiment 1 in that: the second connection section is a four-petal petal-shaped structure, and the end of the petal-shaped petal constitutes the third connection part 114, and the flexible light bar is connected to the two surrounding frames of the support assembly. on the third connecting portion 114 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com