Turbocharger with external ball bearing

A turbocharger and ball bearing technology, which is applied to pump devices, non-variable capacity pumps, gas turbine devices, etc., can solve the problems of excessively long rotating shafts, high-speed noise sensitivity, inconvenient layout, etc., and achieve volume reduction. , Improve rigidity and avoid the effect of oil aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

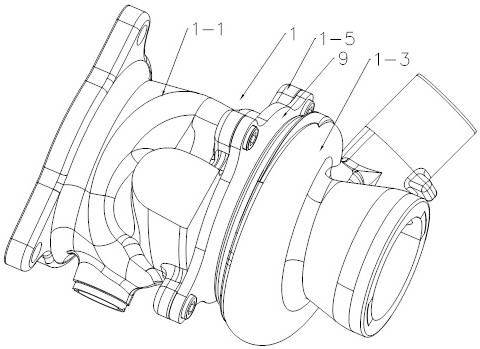

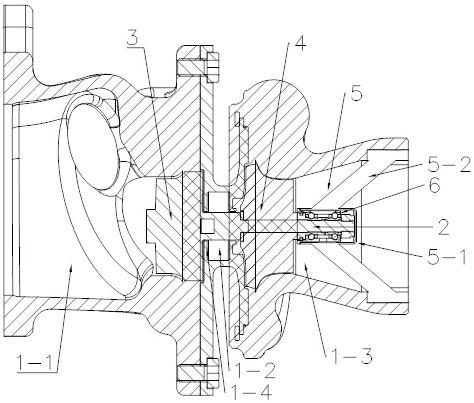

[0027] see Figure 1-4 , the present invention provides a technical solution: a ball bearing 6 external turbine 3 supercharger, including a body shell 1, a rotating shaft 2, a turbine 3 and an impeller 4, wherein the body shell 1 includes turbine chambers connected in sequence Body 1-1, intermediate cavity 1-2, compressed gas cavity 1-3, the turbine cavity 1-1, compressed gas cavity 1-3 are all provided with air inlets and gas outlets, and the turbine 3 is set A turbine is formed in the turbine cavity 1-1, and the impeller 4 is set in the compressor cavity 1-3 to form a compressor. The turbine 3 and the impeller 4 are both connected to the rotating shaft 2 to achieve coaxial linkage. In order to reduce the middle cavity The volume of the body 1-2 and the length of the rotating shaft 2 at the middle cavity 1-2, the support frame body 5 can be detachably connected to the compressed air cavity, and the rotating shaft 2 corresponds to the end of the compressed air cavity 1-3 It i...

specific Embodiment 2

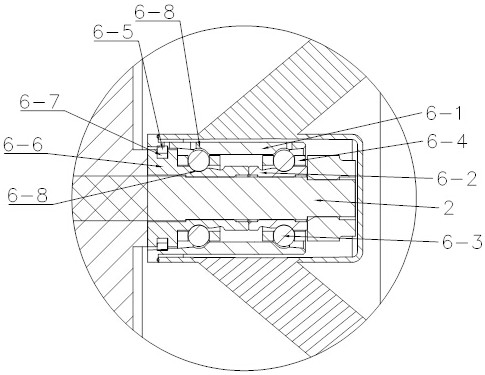

[0034] Such as Figure 5-7 As shown, on the basis of the specific embodiment 1, the outer ring 6-1 of the ball bearing 6 has an oil inlet hole 6-9 and an oil outlet hole respectively between the two rows of pocket ring surfaces 6-8. The oil hole 6-10, and the oil inlet hole 6-9 and the oil outlet hole 6-10 are all set corresponding to the supporting foot 5-2, and the shown supporting foot 5-2 has an oil passage communicated with the bearing outer casing 5-1 Channel 5-4, the oil channel 5-4 communicates with the oil inlet hole 6-9 and the oil outlet hole 6-10 respectively, and at the same time, the corresponding oil channel 5-4 on the connecting palm 5-3 has an oil port 5-5, the body shell 1 is provided with a valve corresponding to the oil port 5-5.

specific Embodiment 3

[0036] Such as Figure 8 As mentioned above, the difference between this specific embodiment and specific embodiment 1 or specific embodiment 2 is that the annular baffles 1-4 on both ends of the intermediate cavity 1-2 face the turbine cavity 1-1, the compressed air cavity 1-3 directions are embedded with sealing gaskets, and the inner ring baffle 1-6 is integrally provided around the rotating shaft 2 in the intermediate cavity 1-2 to form a sealed cavity, and the body shell 1 corresponds to the intermediate cavity 1 -2 has water inlet valve 7 and water outlet valve 8 respectively to form a closed water-cooled waterway, through which the adjacent turbine cavity 1-1 can be cooled to avoid heat conduction into the compressed air cavity 1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com