Sanitation vehicle low-pressure water path with adjustable flushing width

A sanitation vehicle and waterway technology, applied in the field of sanitation vehicles, can solve problems such as the inability to meet the needs of use and the inability to effectively adjust the flushing width of sprinklers, and achieve the effect of real-time adjustable flushing width and expanded applicable scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

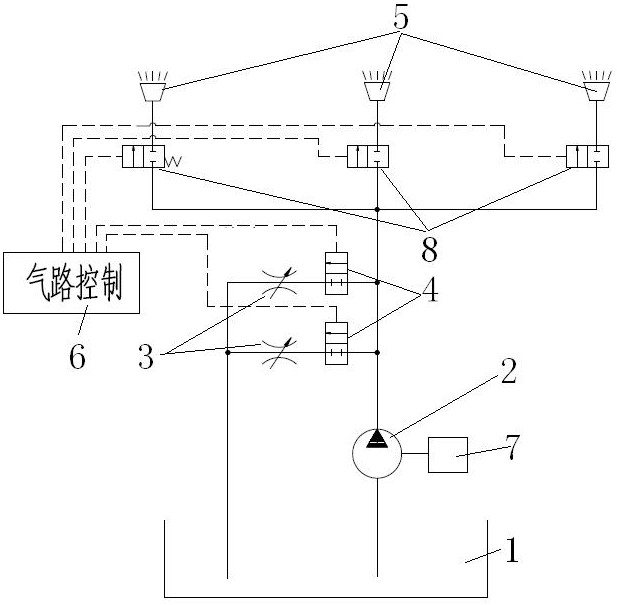

[0022] The low-pressure waterway of the sanitation vehicle with adjustable flushing width of the present invention, such as figure 1 As shown, it includes water tank 1, water pump 2, throttle valve 3, pneumatic cut-off valve 4, sprinkler 5, control air circuit 6 and connecting pipeline, etc. The power is provided by the power take-off port of the chassis 7 of the sanitation vehicle. The water outlet of the water pump 2 is connected to one or more sprinklers 5 through the connecting pipeline. The throttle valve 3 and the water channel cut-off valve 4 are connected in series, and the bypass water channel is finally connected to the water tank 1 .

[0023] A shut-off valve 8 can be arranged between the water outlet of the water pump 2 and the sprinkler 5, and the shut-off valve 8 can be controlled by automatic control methods such as air control.

[0024] When the low-pressure water circuit is in normal operation, the pneumatic cut-off valve 4 on each bypass water circuit is clo...

Embodiment 2

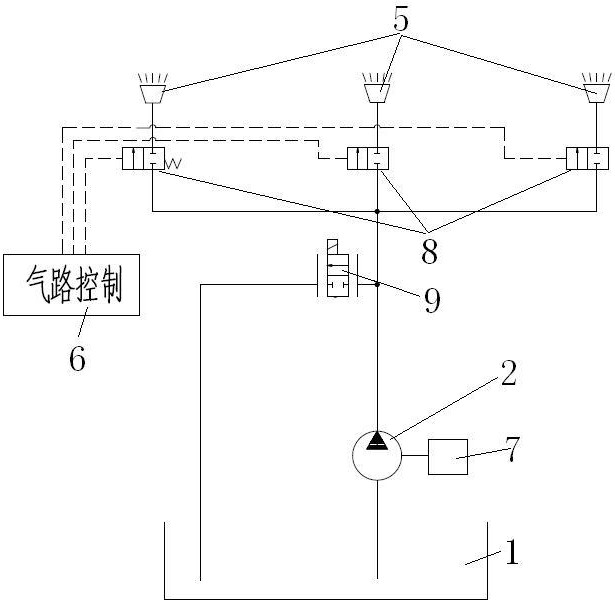

[0028] On the basis of Example 1, in other embodiments, the flow control valve 9 with electric proportional adjustment can also be used in the bypass waterway to conduct waterway on-off and flow control to realize fine control, instead of the throttle valve 3 and the pneumatic cut-off valve 4. The flow control valve with electric proportional adjustment can change the flow rate by using electric control adjustment, instead of the function realized in the case of multiple bypass water circuits in Example 1, such as figure 2 . Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com