Material pressing and feeding device of sewing machine for processing vamp

A sewing machine and transmission device technology, applied in the field of sewing machines, can solve the problems of manpower consumption and hidden safety hazards of workers, and achieve the effect of easy storage and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

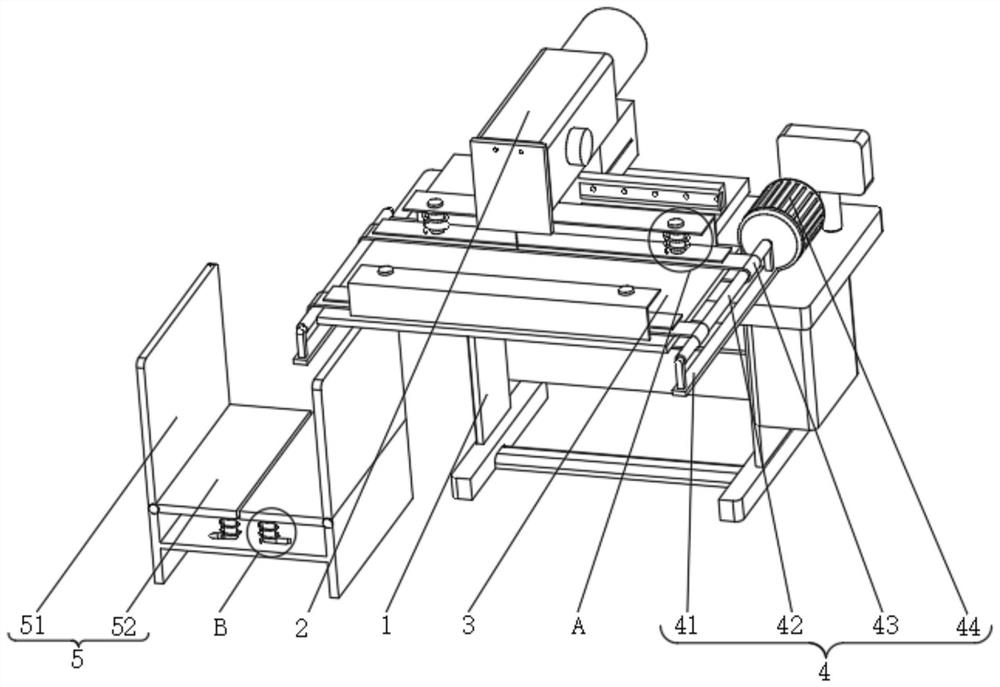

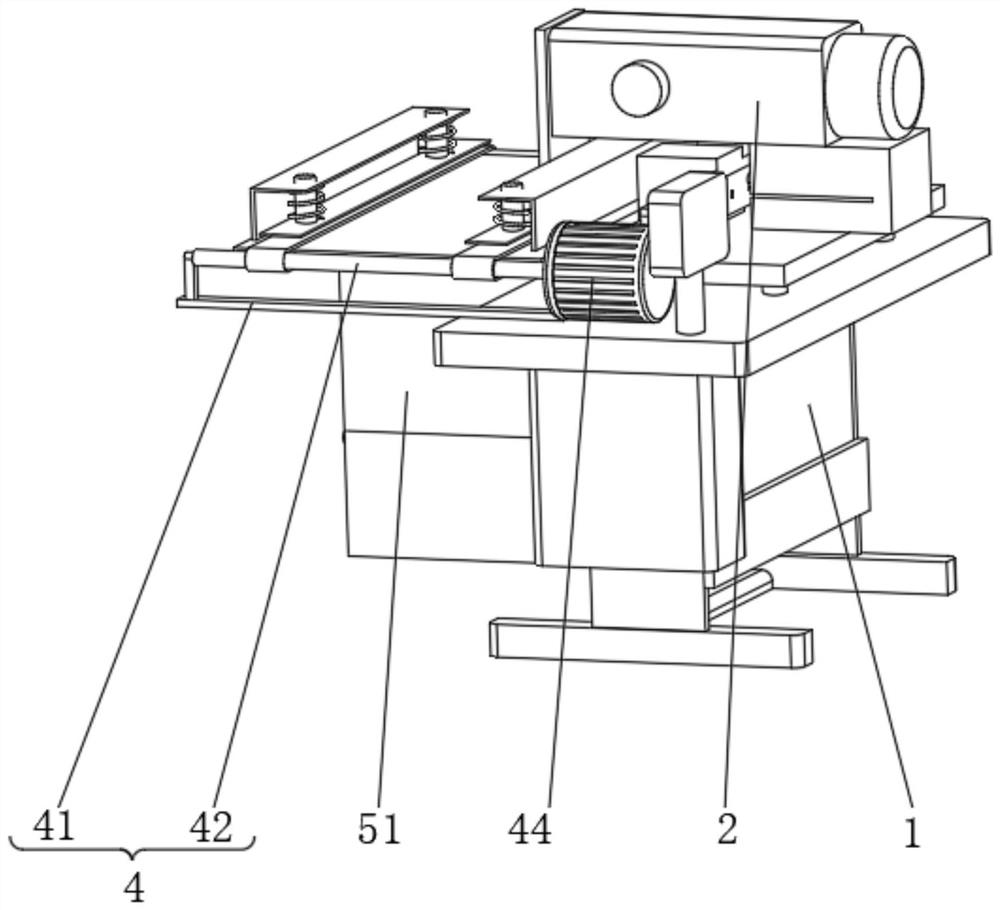

[0021] Example 1, such as Figure 1-4 As shown, the present invention provides a sewing machine pressing and feeding device for shoe upper processing, including a general support 1, a transmission device 4 and a storage device 5, the upper surface of the general support 1 is fixedly connected with the machine head 2, and the upper surface of the general support 1 The upper surface of the side away from the machine head 2 is fixedly connected with a fixed plate 3 , and the surface of the fixed plate 3 is provided with a transmission device 4 .

[0022] Let's talk about the specific settings and functions of the conveying device 4 and the storage device 5 in detail.

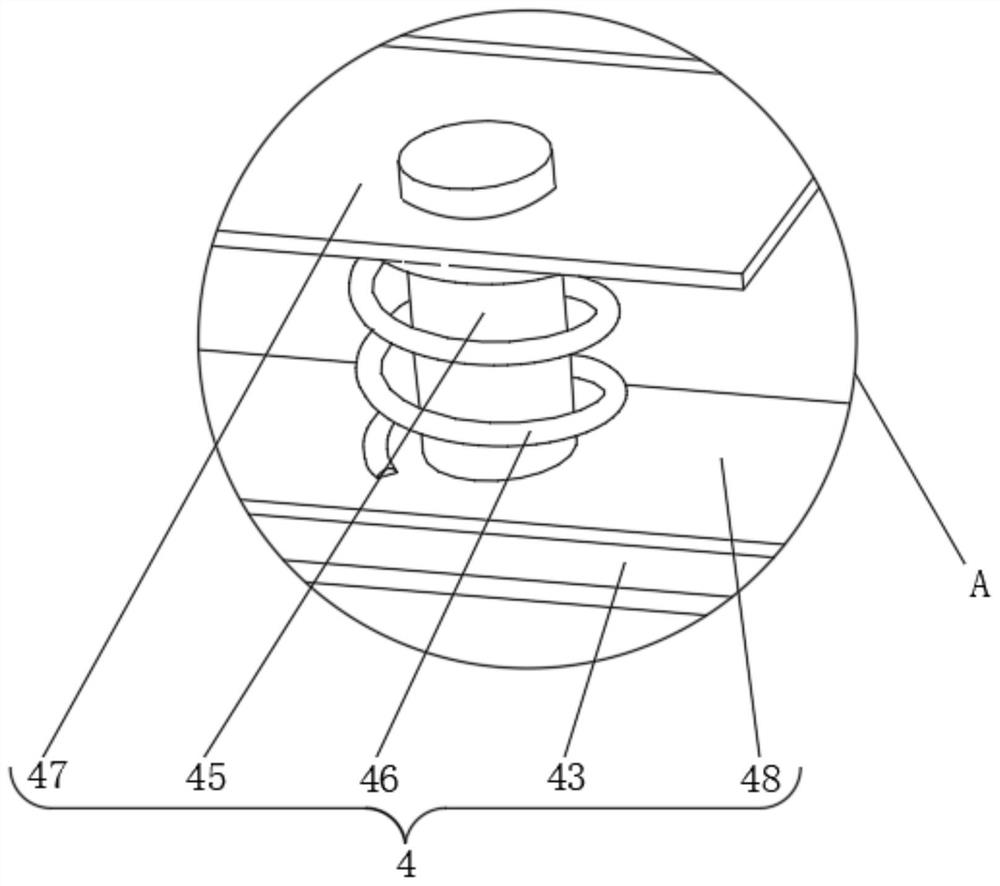

[0023] Such as figure 1 and image 3 As shown, the transmission device 4 includes two fixed mounts 41, the sides of the two fixed mounts 41 are rotatably connected with a roller bar 42, and both sides of the roller bar 42 are covered with conveyor belts 43, and the total support 1 is close to the end surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com