Fully-automatic watch cover fitting and pressing equipment

A lamination equipment, fully automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low labor rate and low degree of automation, and achieve the effect of improving efficiency and saving assembly manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

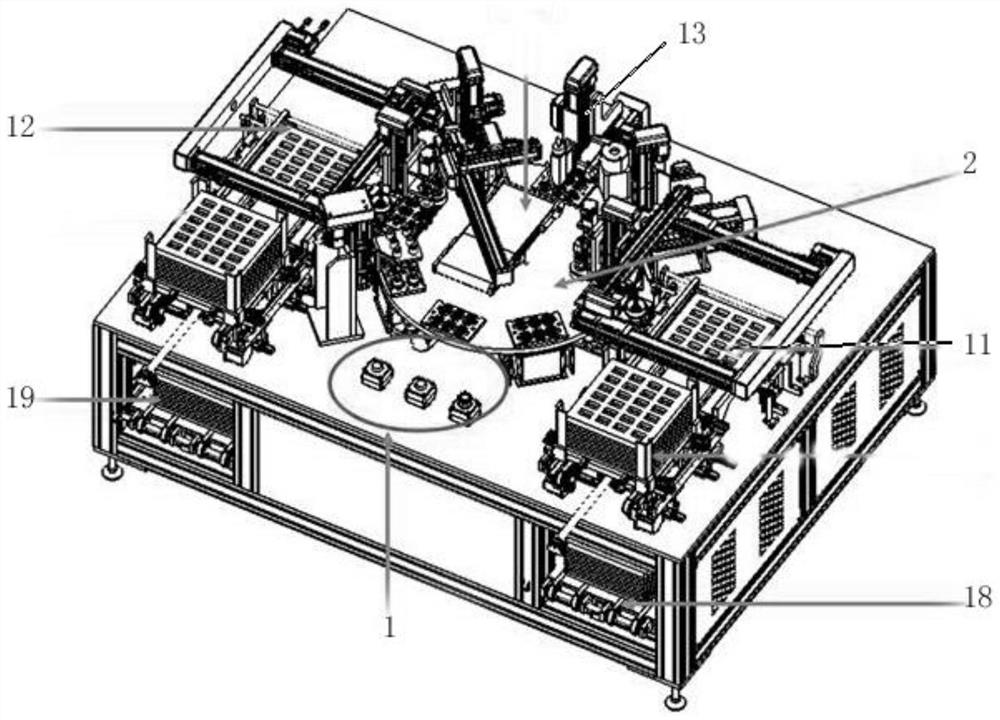

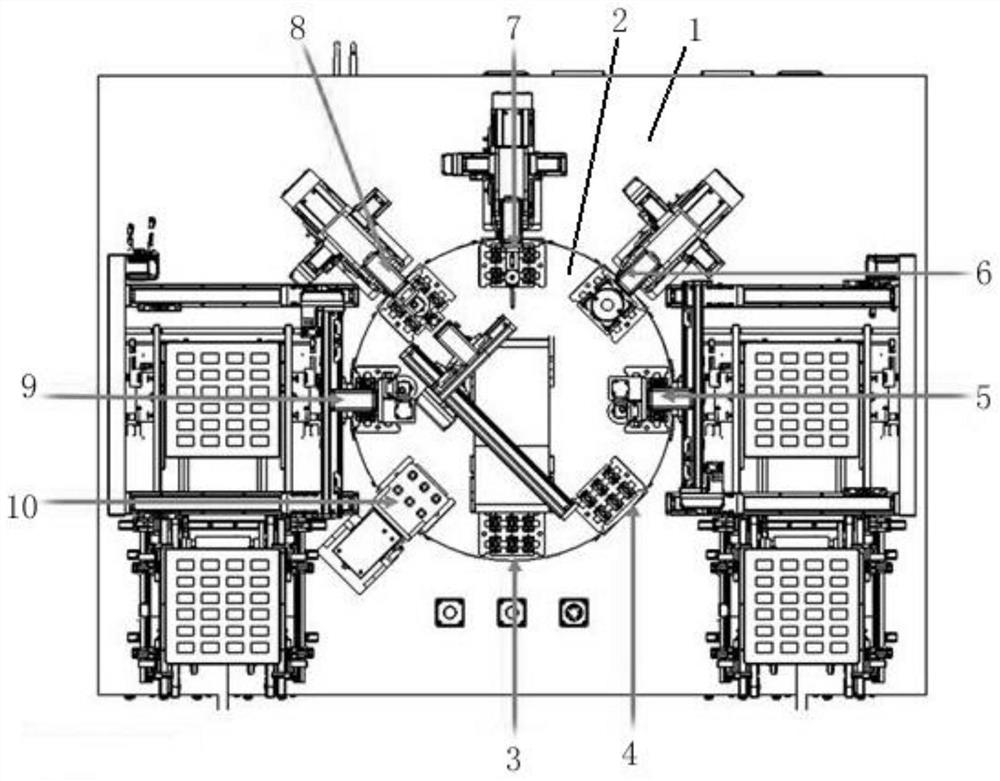

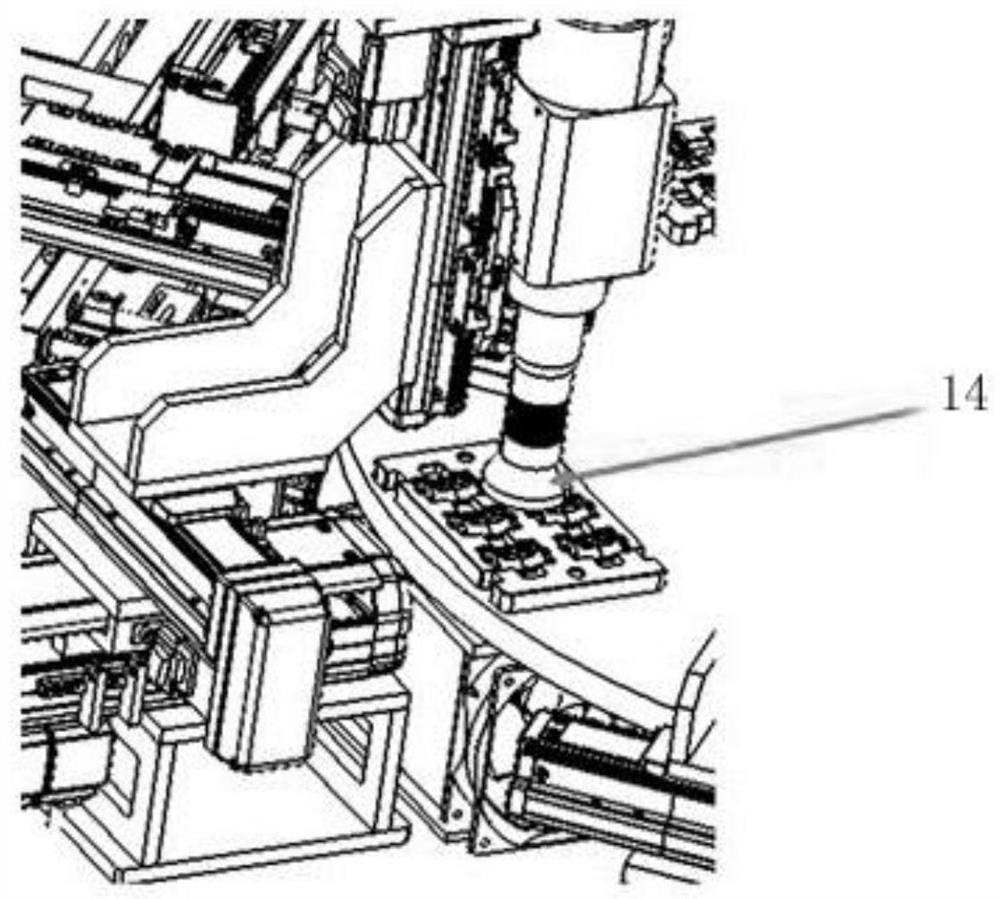

[0021] See Figure 1 to Figure 6 As shown, the present invention has a kind of full-automatic table cover automatic laminating press-fitting equipment, has workbench 1; The center of described workbench 1 has the high-precision high-speed rotating platform 2 of autorotation, and the high-precision high-speed rotating platform 2 There is a first station 3 for putting in the carrier plate around the watch, along the counterclockwise direction of the first station 3 for putting in the carrier plate, there are the second station 4, the third station 5 for putting in the raw materials of the watch case, and the second station for plasma cleaning the surface of the watch case. Four stations 6, fifth station 7 for dispensing, sixth station 8 for visual inspection of dispensing bubbles, seventh station 9 for inputting surface raw materials and eighth station 10 for splitting and pressing, the second station 4 It is an empty position, the third station 5 for inputting watch case raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com