A welding jig positioning device for automobile stamping parts

A technology for automotive stamping parts and welding fixtures, which is applied to welding equipment, auxiliary devices, vehicle parts, etc., can solve problems such as deformation and lifting, and fixtures that cannot be solved, so as to avoid lifting or deformation, good practical value, and clean working environment neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

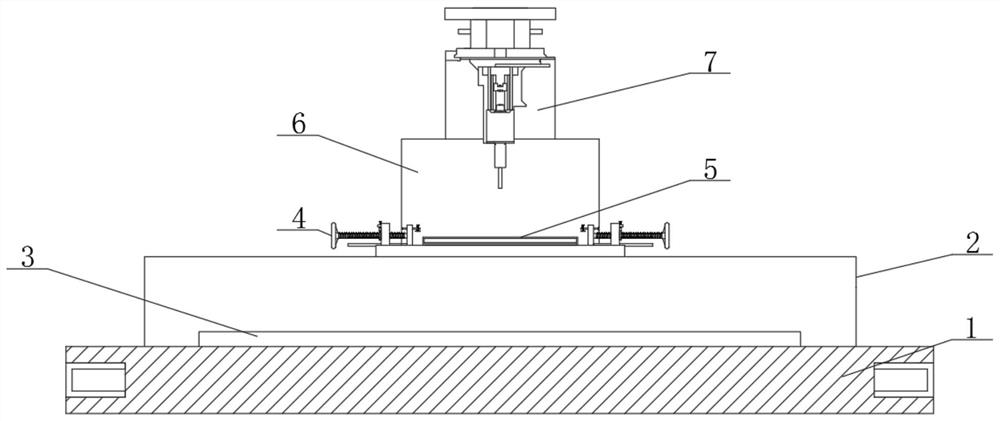

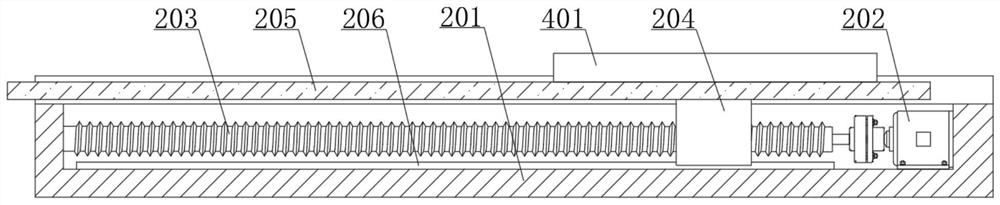

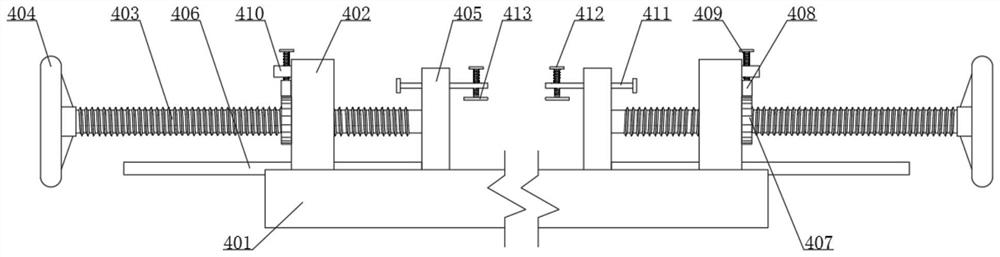

[0026] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the present invention provides a technical solution:

[0027]A welding jig positioning device for automobile stamping parts, comprising a base 1 and a collection box 3, the upper end of the base 1 is fixedly connected with a mobile device 2, the mobile device 2 includes a fixed shell 201 and a mobile motor 202, and the lower end of the fixed shell 201 is fixed to the base 1 Connection, the fixed housing 201 is fixedly connected with a mobile motor 202, the end of the main shaft of the mobile motor 202 is fixedly connected with a mobile threaded rod 203, the other end of the mobile threaded rod 203 is rotationally connected with the fixed case 201, and the outer side of the mobile threaded rod 203 is spirally connected with a threaded block 204 , the upper end surface of the threaded block 204 is fixedly connected with a sliding table 205, the setting of the sliding table 205 ensures that th...

Embodiment 2

[0030] In embodiment 2, the same part as embodiment 1 will not be repeated, the difference is that when the automobile stamping part is thinner because of its thickness, and when the height of the welded automobile stamping part is less than 2 / 3 of the height of the clamping plate 405, The clamping work by the simple clamping plate 405 cannot guarantee its stability. At this time, the sliding plate 411 is moved to the center, and then the lower pressing plate 413 is located on both sides of the welding part of the automobile stamping part, and then driven down by rotating the pressing threaded rod 412. The pressing plate 413 moves downward, and now the lower pressing plate 413 can press the automobile stamping part to avoid its warping or extrusion deformation, so as to ensure the normal welding work of the automobile stamping part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com