Swing sand screening device for buildings

A swing type, construction technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of reduced screening speed, small sand movement range, small screen vibration range, etc., to improve filtration efficiency and improve adaptability , to avoid the effect of being blocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

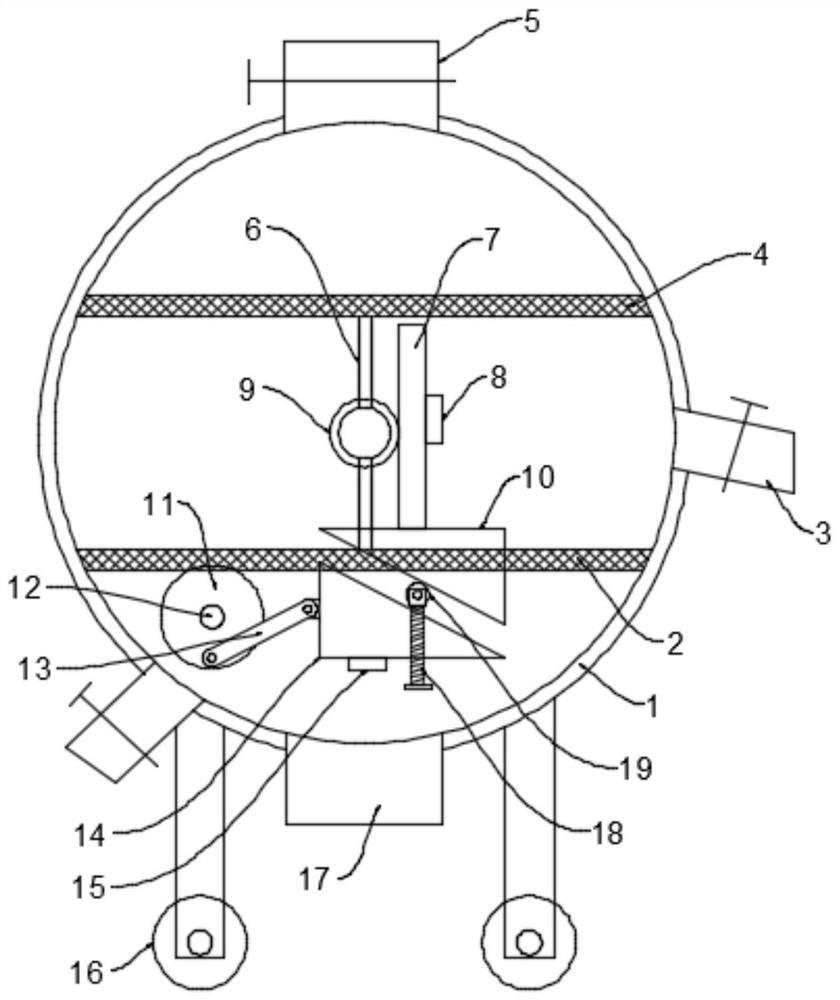

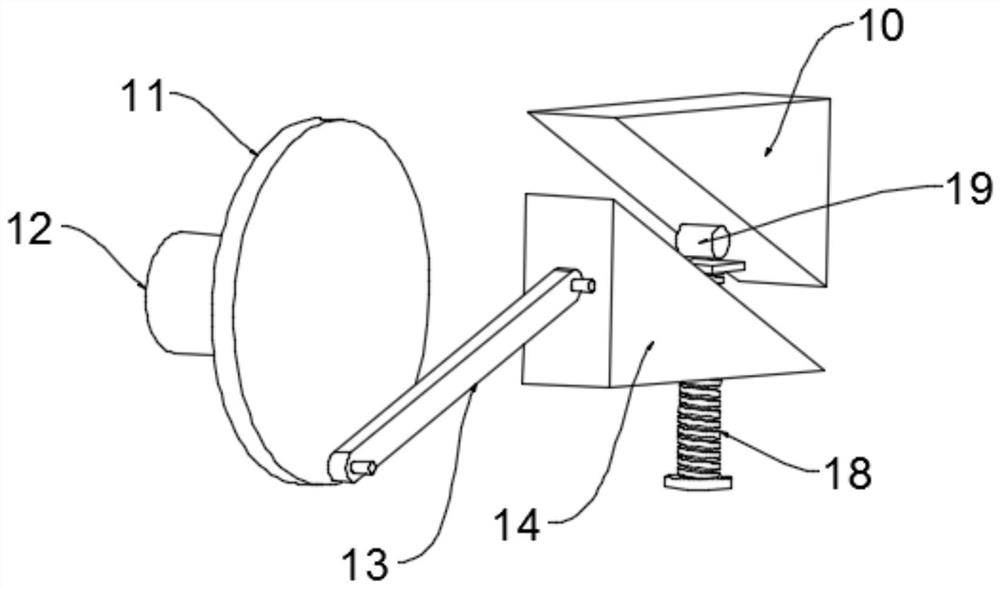

[0023] see Figure 1~2 , in the embodiment of the present invention, a kind of swing sand screening device for building, comprises cylinder 1, first screen 4 and second screen 2, and the bottom of described cylinder 1 is uniformly and symmetrically fixedly installed with support leg, and support leg Rollers 16 are installed at the bottom to facilitate the movement of the device. The top of the cylinder 1 is provided with a feed inlet 5, and a valve is installed on the feed inlet 5. A mounting shaft is installed on the center line of the cylinder 1. The cylinder 1 The first screen 4 and the second screen 2 are horizontally arranged on the upper and lower sides of the inner installation shaft respectively. The mesh of the first screen 4 is larger than the mesh of the second screen 2. A first discharge port 3 is provided under the screen 4 and the second screen 2 respectively, and the two first discharge ports 3 are respectively located on both sides of the cylinder 1. Valves are...

Embodiment 2

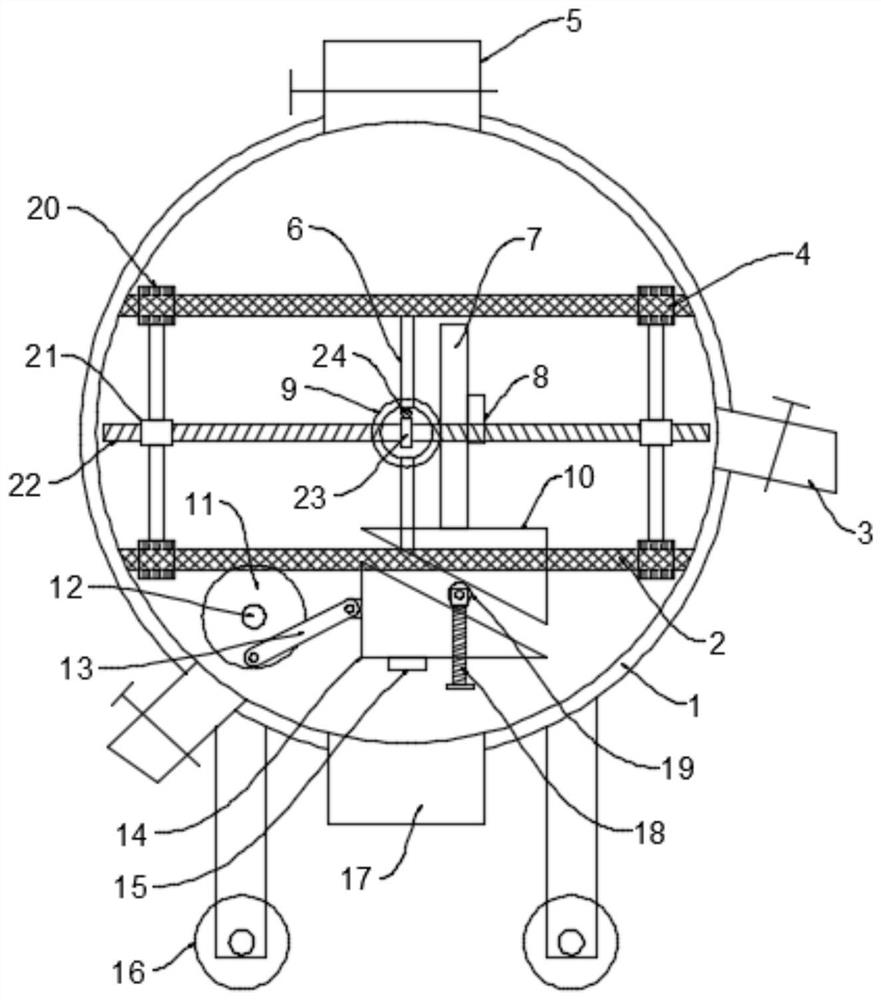

[0025] see image 3 The difference between this embodiment of the present invention and Embodiment 1 is that a two-way screw rod 22 runs through the installation shaft horizontally, the two-way screw rod 22 is rotationally connected with the installation shaft, and the threaded sections on both sides of the two-way screw rod 22 are threaded. There are internally threaded sleeves 21, the top and bottom of the internally threaded sleeves 21 are fixed with poles, both ends of the first screen 4 and the second screen 2 are equipped with brush sleeves 20, and the inner walls of the brush sleeves 20 are provided with The hairbrush in contact with the first screen cloth 4 and the second screen cloth 2 is fixedly connected with the brush cover 20 adjacent to the pole, and the two-way screw rod 22 is fixedly installed with a worm gear 23 on the rod end in the installation shaft. A worm 24 meshing with the worm wheel 23 is inserted on the installation shaft, and the other end of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com