Mutual inductor winding device

A winding device and transformer technology, applied in the field of transformers, can solve problems such as uneven winding, difficult quality assurance, and low work efficiency, and achieve the effects of improving winding efficiency, reducing operating intensity, and stabilizing winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

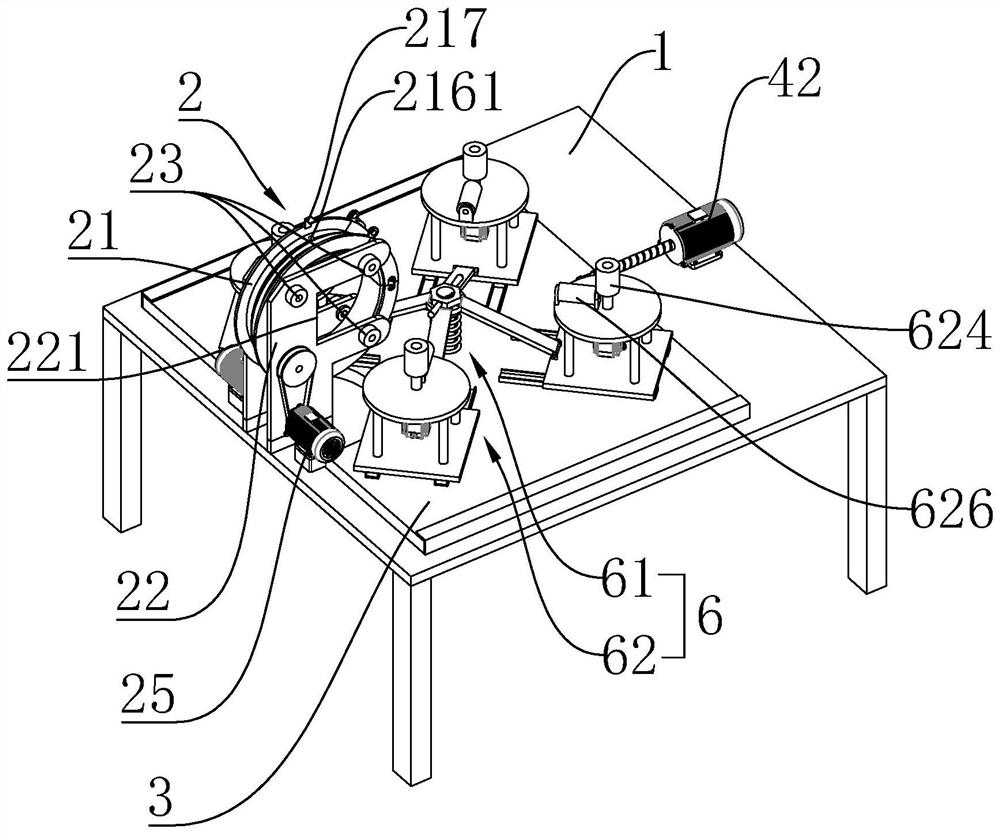

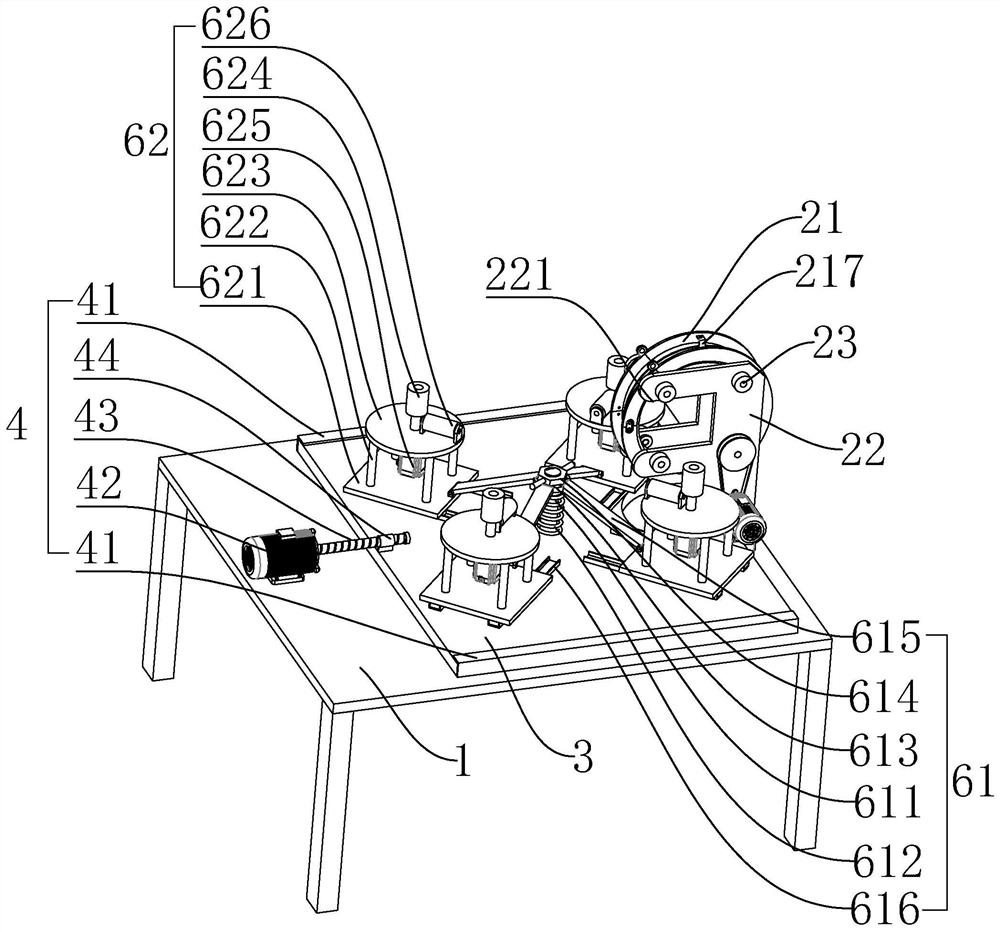

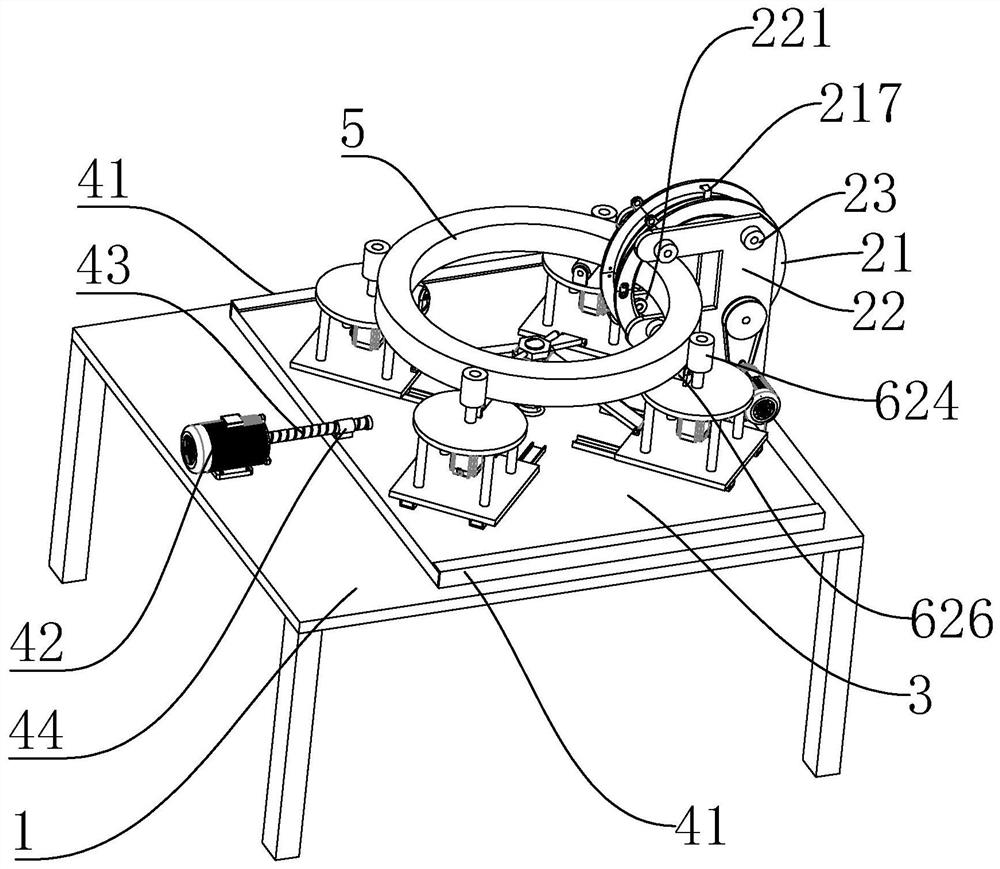

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] Such as Figure 1-3 As shown, a transformer winding device includes a workbench 1. A coil winding mechanism 2 for winding a coil on a transformer 5 is provided on the workbench 1. A ring for storing copper wires is rotatably installed on the coil winding mechanism 2. Shape winding reel 21; Coil winding mechanism 2 front side workbench 1 is provided with sliding plate 3, and sliding plate 3 is close to or away from coil winding mechanism 2 through sliding mechanism 4, and is provided with for supporting clip on sliding plate 3. The clamping and rotating mechanism 6 that tightens the transformer 5 and can make it rotate.

[0036] The winding reel 21 vertically passes through the transformer 5 and rotates around the transformer 5, while the transformer 5 rotates horizontally under the action of the clamping and rotating mechanism 6, and the copper wire on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com