Test method for synchronously monitoring DCR change in secondary battery cycle process

A cycle process, secondary battery technology, applied in the measurement of electrical variables, measurement of electricity, measurement devices, etc., can solve the problems of DCR not being able to monitor, not as accurate as data, and troublesome to operate, so as to reduce time waste and prevent travel accidents. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

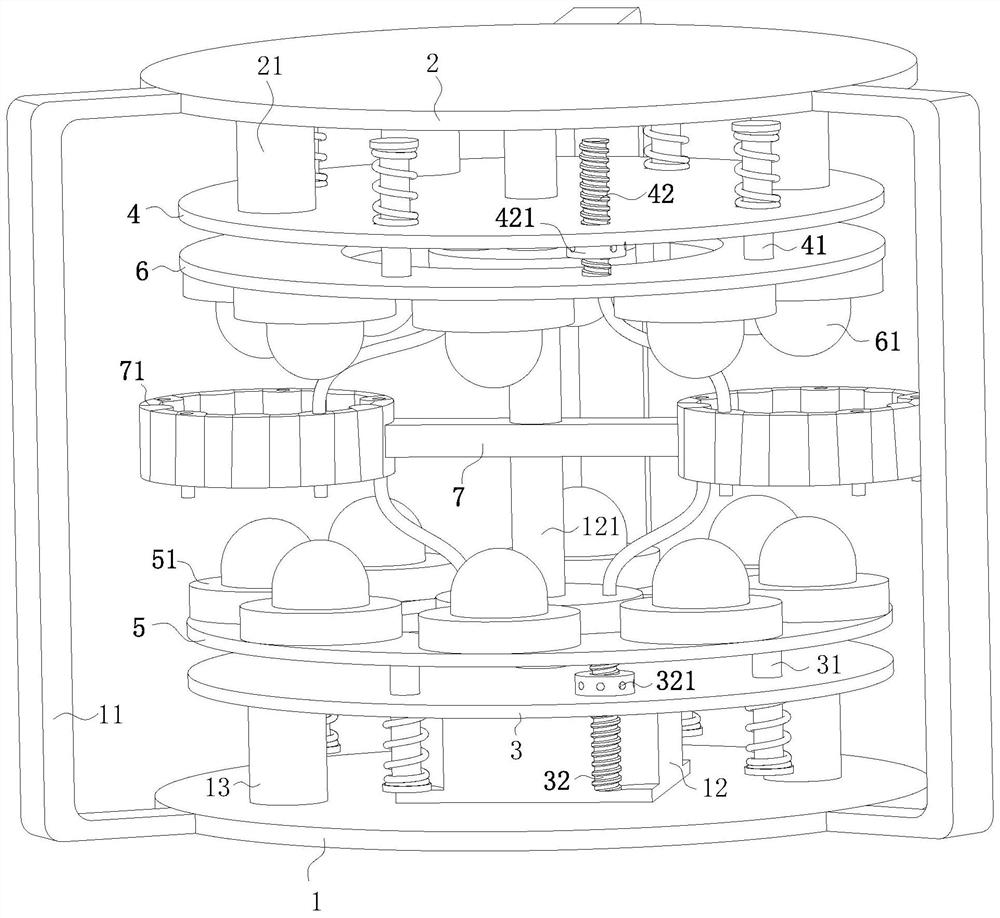

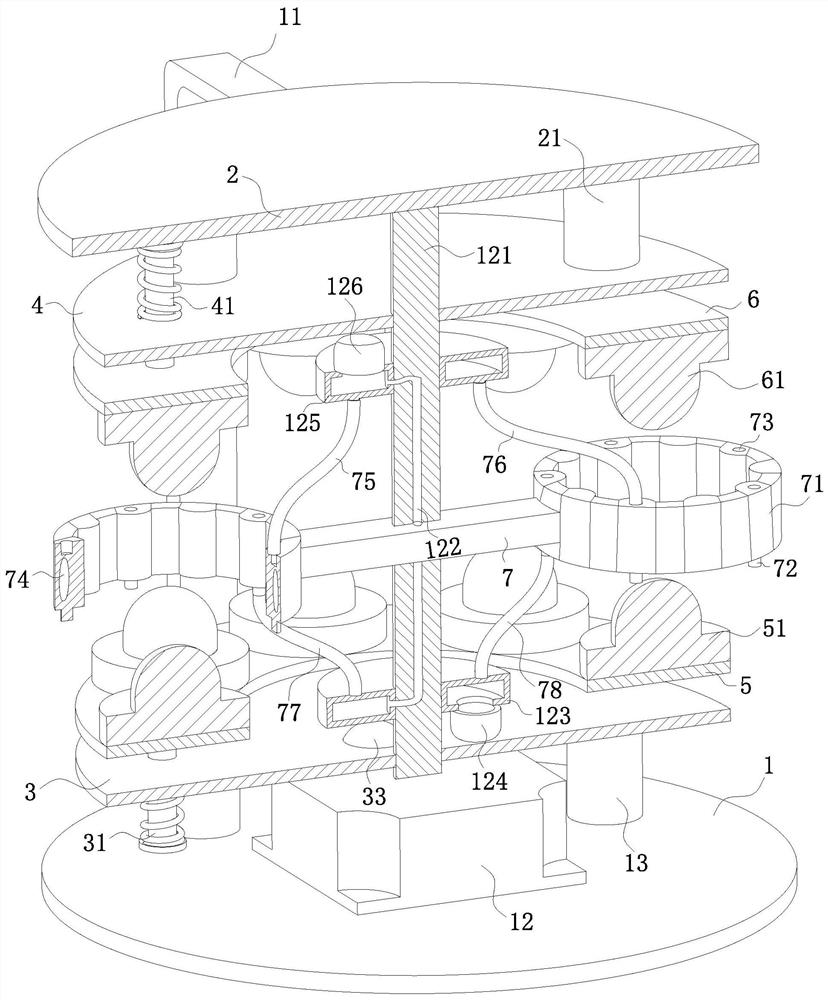

[0058] As an embodiment of the present invention, it is characterized in that: the lower surface of the lower mounting plate 5 is fixedly connected with a lower screw 32; the lower screw 32 passes through the lower fixing plate 3; Locating nut 321; The lower locating nut 321 is located between the lower mounting plate 5 and the lower fixing plate 3; The side of the lower locating nut 321 is uniformly provided with a rotation hole; The lower guide rod is equipped with a spring; Between the lower guide rod and the lower surface of the lower fixing plate 3; the upper surface of the upper mounting plate 6 is fixedly connected with an upper screw 32; the upper screw 32 passes through the upper fixing plate 4; The positioning nut 421; the upper positioning nut 421 is located between the upper mounting plate 6 and the upper fixing plate 4; the upper positioning nut 421 is evenly provided with a rotation hole on the side; the upper guide rod 41 is equipped with a spring; the spring Lo...

Embodiment 1

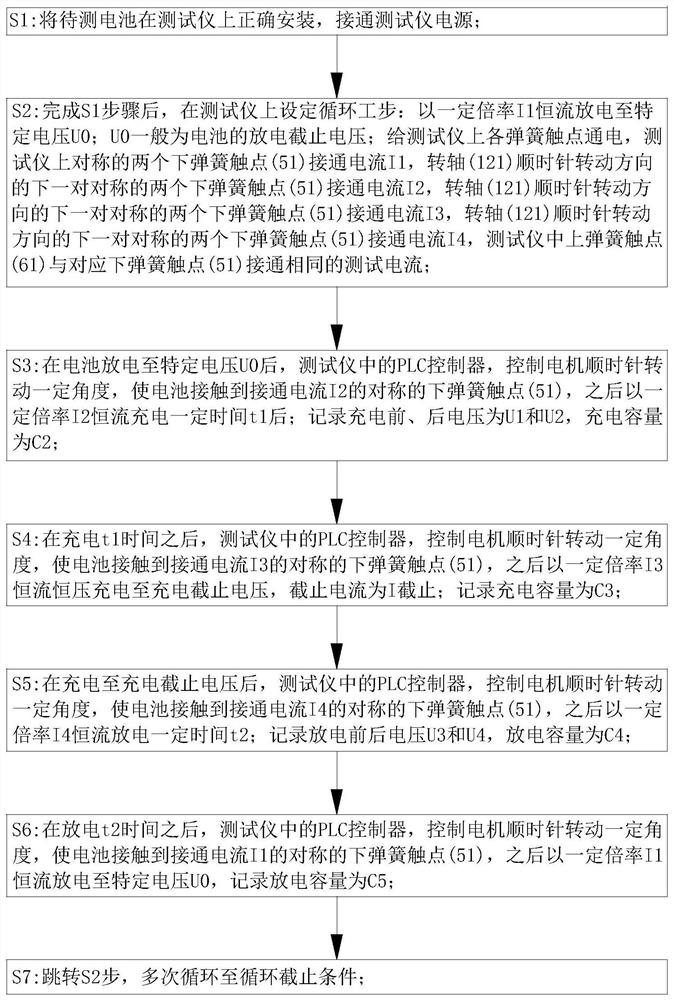

[0073] Embodiment 1: A sodium-ion battery 1# with a nominal capacity of 100Ah is selected, and a 1C charge-discharge cycle is performed under normal temperature conditions. The test process is as follows:

[0074] (1) Correctly install the 1# battery to be tested on the tester, turn on the power of the tester; and set the cycle steps on the tester as follows: 1C current is 1C 标 ;Electrify each spring contact on the tester, two symmetrical lower spring contacts (51) on the tester connect current 1C, the next pair of symmetrical lower spring contacts of the rotating shaft (121) clockwise rotation direction (51) Turn on the current 2.25C, the next pair of symmetrical two lower spring contacts (51) in the clockwise rotation direction of the rotating shaft (121) turn on the current 1C, and the next pair of symmetrical in the clockwise rotating direction of the rotating shaft (121) The two lower spring contacts (51) of the tester are connected with a current of 3C, and the upper spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com