Ammonium oil explosives delivery method and ammonium oil explosives on-site mixing method

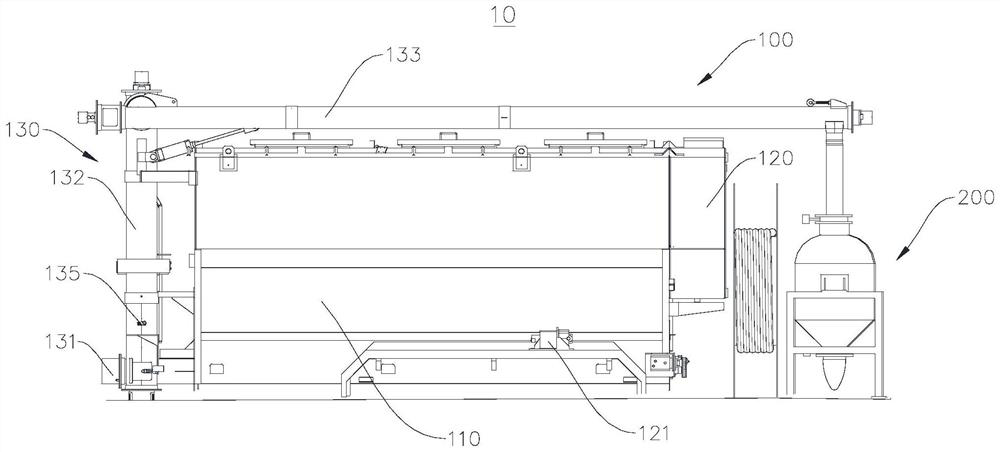

A technology of ammonium oil explosives and on-site mixing, which is applied to explosives, explosives processing equipment, offensive equipment, etc. It can solve the problems of affecting operating efficiency, small operating range, and short transportation distance, and avoid on-site bagging and manual handling. The effect of expanding the scope of automatic charging operation and improving the ability of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a method for delivering ammonium oil explosives and an on-site mixing method, including:

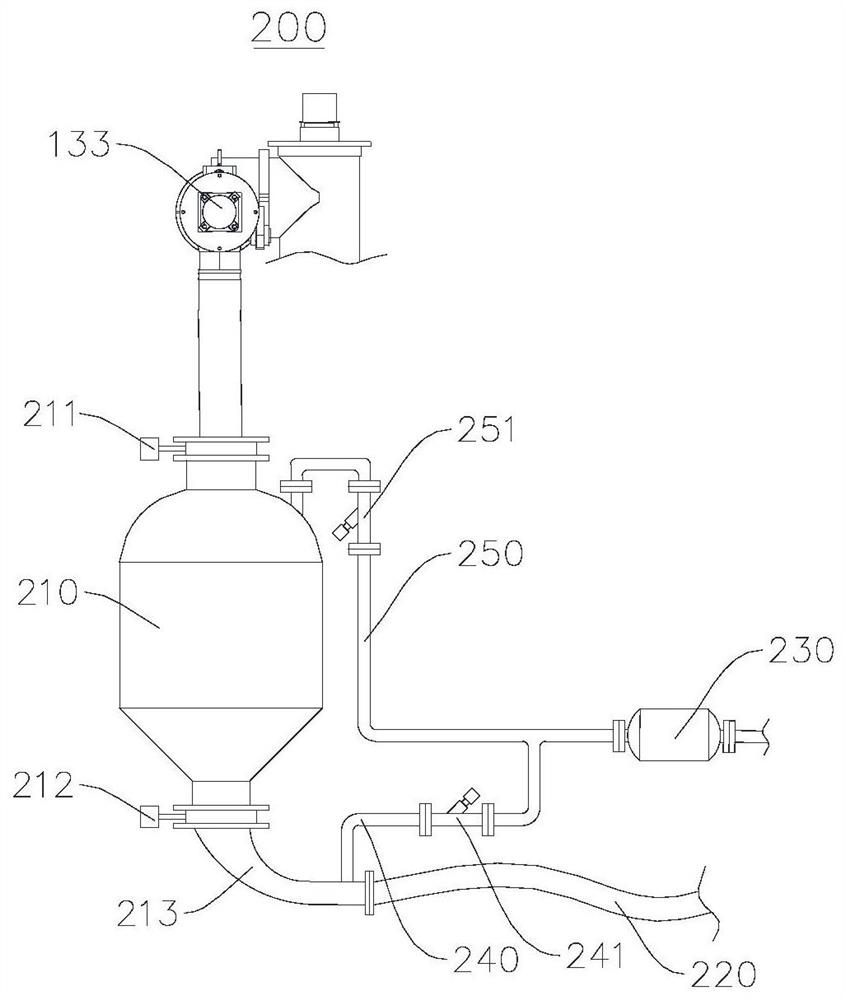

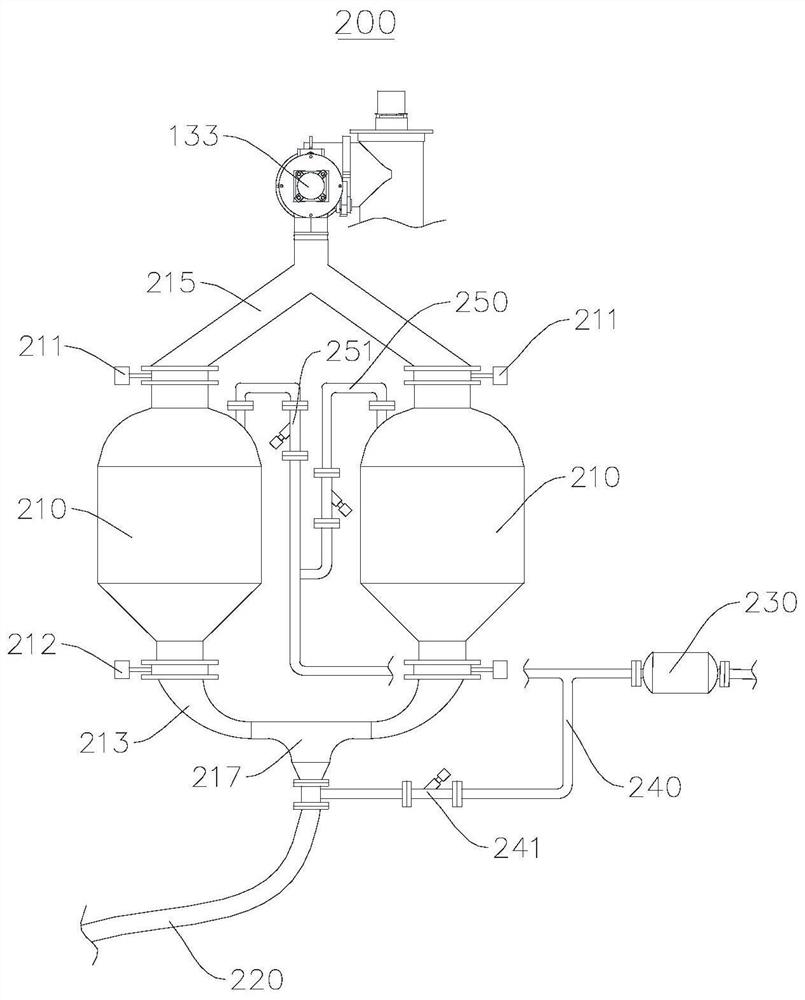

[0062] The horizontal distance between the target blast hole and the ammonium oil explosives mixing truck is 50m, and there is no height difference. The feeding volume of the storage container is set at 150kg, the feeding rate of the screw conveyor unit is 200kg / min, and the screw speed of the discharge conveyor is 90rpm. The conveyor screw speed was 110 rpm and the feed conveyor screw speed was 150 rpm. The inner diameter of the feeding pipe used is φ76mm, the length is 50m, and there is a 90° right-angle bend along the outlet 35m.

[0063] The parameters are set to the compressed air supply volume of 3.0m 3 / min, the pressure of the compressed air is 0.2MPa, the pressure of the pulse gas is set to 0.16MPa, the pulse cycle is 2.0s on, 1.0s off, the gas consumption is small at this time, and the particle size and detonation velocity performance of the ammo...

Embodiment 2

[0067] This embodiment provides a method for delivering ammonium oil explosives and a charging method, including:

[0068] The horizontal distance between the target blast hole and the ammonium oil explosives mixing truck is 30m, and there is no height difference. The feeding volume of the storage container is set to 150kg, the feeding rate of the screw conveyor unit is 200kg / min, and the screw speed of the discharge conveyor is 90rpm. The conveyor screw speed was 110 rpm and the feed conveyor screw speed was 150 rpm. The inner diameter of the feeding pipe used is φ76mm and the length is 30m.

[0069] The parameters are set to the compressed air supply volume of 3.0m 3 / min, the pressure of compressed air is 0.2MPa, the pressure of pulse gas is set to 0.12MPa, and the pulse cycle is 1.0s on and 1.0s off. At this time, the gas consumption is small, and the transportation process has little influence on the particle size and detonation velocity of ammonium oil explosives. .

...

Embodiment 3

[0073] This embodiment provides a method for delivering ammonium oil explosives and a charging method, including:

[0074] The horizontal distance between the target blast hole and the ammonium oil explosives mixing truck is 15m, and the height difference is 8m. The feeding volume of the storage container is set to 150kg, the feeding rate of the screw conveyor unit is 200kg / min, and the screw speed of the discharge conveyor is 90rpm. The conveyor screw speed was 110 rpm and the feed conveyor screw speed was 150 rpm. The inner diameter of the feeding pipe used is φ76mm and the length is 30m.

[0075] The parameters are set to the compressed air supply volume of 3.0m 3 / min, the pressure of compressed air is 0.2MPa, the pressure of pulse gas is set to 0.11MPa, and the pulse cycle is 1.0s on and 1.0s off. At this time, the gas consumption is small, and the transportation process has little influence on the particle size and detonation velocity of ammonium oil explosives. .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com