A Design Method for Reinforced Structure of Pile-Slab Wall on Soil Foundation Road Shoulder

A technology for strengthening structures and design methods, which is applied in the direction of foundation structure engineering, sheet pile walls, roads, etc., can solve the problems of large investment, high safety risks, and difficult construction of reinforced pile projects, and achieve simple construction, good economy, and high construction efficiency. Simple and Safe Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

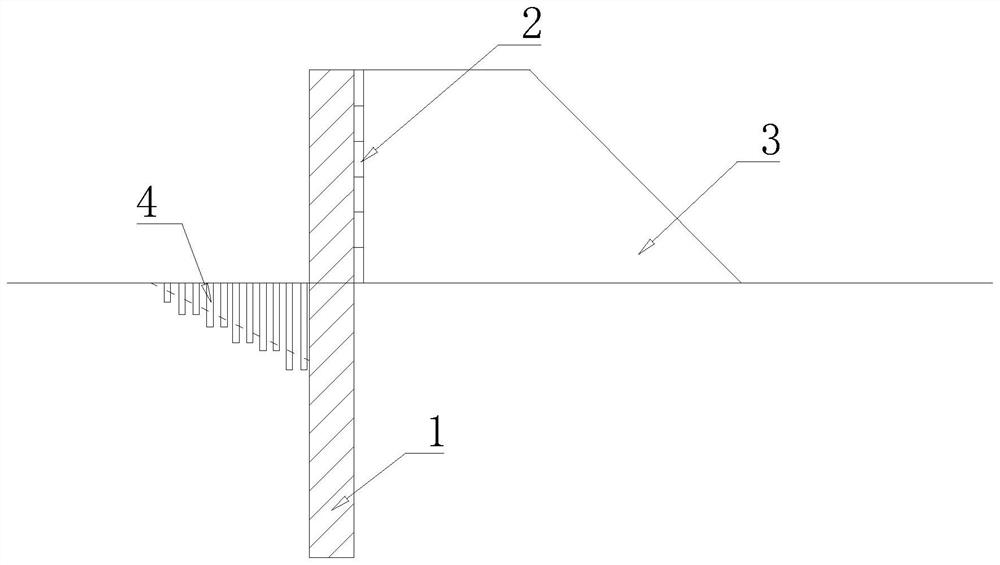

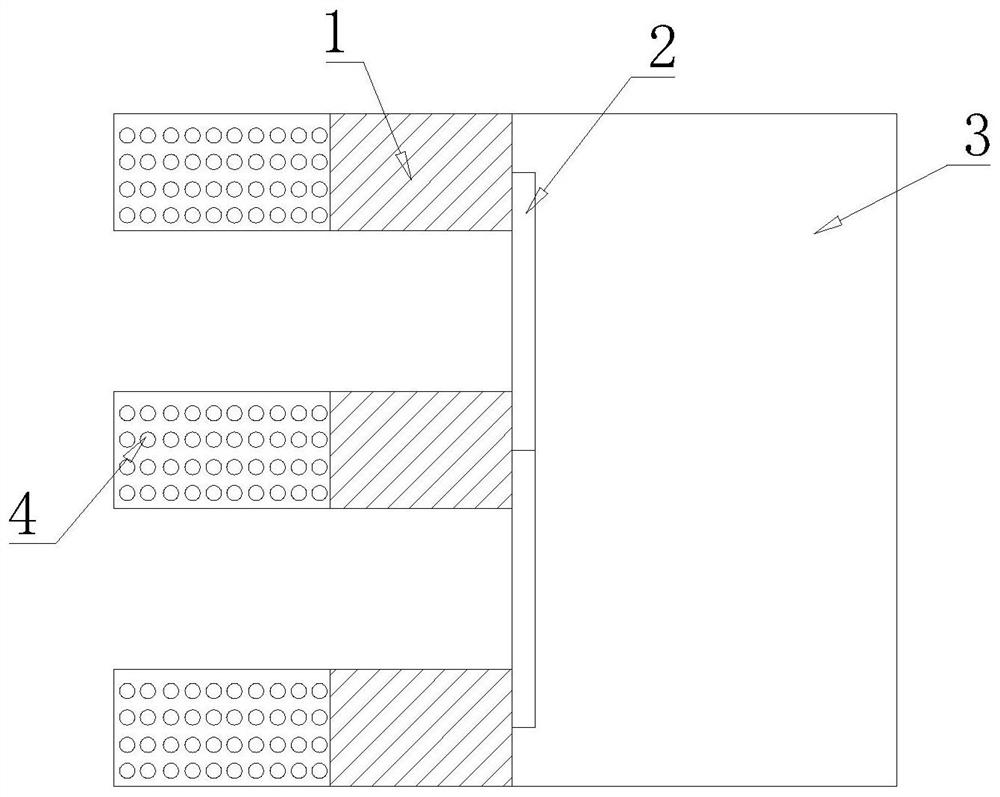

[0053] Such as Figure 1-2 As shown, this embodiment provides a soil foundation road shoulder pile-slab wall reinforcement structure, including a pile-slab wall structure, a reinforcement 4 and an embankment project 3;

[0054] The pile-slab wall structure includes reinforcement piles 1 and soil retaining boards 2. The reinforcement piles 1 are arranged longitudinally along the line in the foundation at intervals. The tops of the reinforcement piles 1 protrude from the foundation. The quantity of soil plate 2 is at least two, and at least two soil retaining plates 2 are arranged on the foundation of reinforcement pile 1 side along vertical direction, and the two ends of soil retaining plate 2 are connected with adjacent described reinforcement pile 1 respectively, Specifically, the longitudinal spacing of the reinforcing piles 1 is generally 5-6m.

[0055] The number of reinforcements 4 is at least two, and at least two reinforcements 4 are buried in the foundation on the oth...

Embodiment 2

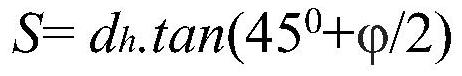

[0089] Such as Figure 1-2 As shown, the present embodiment specifically demonstrates the design method for the embankment project 3 in construction, and the specific design process:

[0090] Ballastless track high-speed railway embankment project 3 on a soil foundation, the foundation condition is hard plastic silty clay (bulk density 19kN / m, cohesion 18kPa, internal friction angle 20°), filling height 10m (group A, B filler, The bulk density is 20kN / m, and the comprehensive internal friction angle is 35°).

[0091] S1: Calculating the active earth pressure of the embankment filling soil behind the shoulder pile-slab wall;

[0092]

[0093] If the safety factor is 1.2, the design active earth pressure is 405kN / m

[0094] S2: Draft the pile length and pile section of the reinforced pile 1 in the pile-slab wall structure;

[0095] The cross-sectional size of the reinforcement pile 1 for the pile-sheet wall is proposed to be 2m (width)×3m (thickness), and the length of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com