Waste lubricating oil deep refining process and system

A waste lubricating oil, advanced refining technology, which is applied in the direction of lubricating compositions, etc., can solve the problems of excessive refining agent addition, energy waste, waste of resources and the environment, and achieve cost savings in advanced refining, reduce solvent usage, and reduce impurity content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

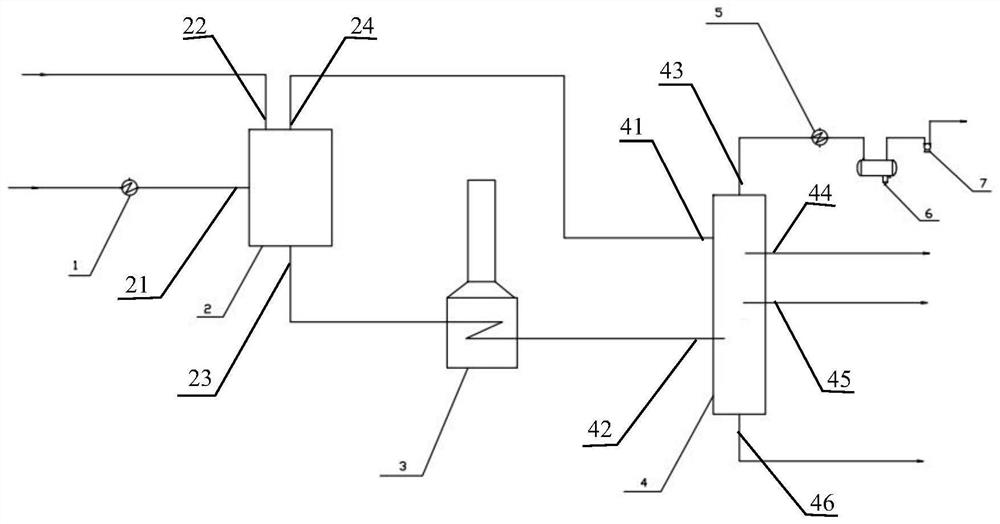

[0050] A waste lubricating oil advanced refining process system has the following structure:

[0051] Including heater 1, refining reactor 2, heating furnace 3, fractionation tower 4, cooler 5, receiving tank 6 and vacuum pump 7; refining reactor 2 includes inlet one 21, inlet two 22, outlet 23 And gas outlet one 24; Feed port one 21 links to each other with heater 1; Fractionation column 4 comprises feed port three 41, feed port four 42, gas outlet two 43, first side line 44, second side line 45 and fractionation remaining Material outlet 46; feed port three 41 is communicated with gas outlet one 24, and feed port four 42 is communicated with discharge port 23, and also includes heating furnace 3 between feed port four 42 and discharge port 23, gas outlet two 43 is connected in series with cooler 5, receiving tank 6 and vacuum pump 7 through pipelines in sequence.

[0052] working principle:

[0053] After the preliminary refined waste lubricating oil (i.e. crude oil) is he...

Embodiment 2

[0056] A deep refining process for waste lubricating oil, comprising the following steps:

[0057] (1) Preliminarily refining the waste lubricating oil by a conventional method to obtain crude oil;

[0058] (2) The crude oil is heated to 200°C by the heater 1 and then enters the refining reactor 2, mixed with furfural at a mass ratio of 0.75:1, and solvent refined in the refining reactor 2. After the solvent is sufficiently refined, the alkaline additive sodium hydroxide is added, and the solvent-refined crude oil and sodium hydroxide are catalytically polymerized for 2 hours under normal pressure at a reaction temperature of 200° C. to obtain the base oil.

[0059] (3) Make the base oil enter the heating furnace 3 for heating, and the heating temperature is 330°C.

[0060] (4) The heated base oil obtained in step (3) enters the fractionation tower 4 for fractionation, wherein the fractionation pressure is an absolute pressure of 150 Pa, and the first-line refined oil is sepa...

Embodiment 3

[0063] A deep refining process for waste lubricating oil, comprising the following steps:

[0064] (1) Preliminarily refining the waste lubricating oil by a conventional method to obtain crude oil;

[0065] (2) The crude oil is heated to 190°C by the heater 1 and then enters the refining reactor 2, mixed with methyl pyrrolidone at a mass ratio of 0.6:1, and solvent refined in the refining reactor 2. After the solvent is sufficiently refined, the alkaline additive sodium hydroxide is added, and the solvent-refined crude oil and sodium hydroxide are catalyzed and polymerized under normal pressure for 1 hour at a reaction temperature of 190° C. to obtain a base oil.

[0066] (3) Make the base oil enter the heating furnace 3 for heating, and the heating temperature is 350°C.

[0067] (4) The heated base oil obtained in step (3) enters the fractionation tower 4 for fractionation, wherein the fractionation pressure is an absolute pressure of 100 Pa, and the first-line refined oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com