Disposable absorbent article and absorbent core

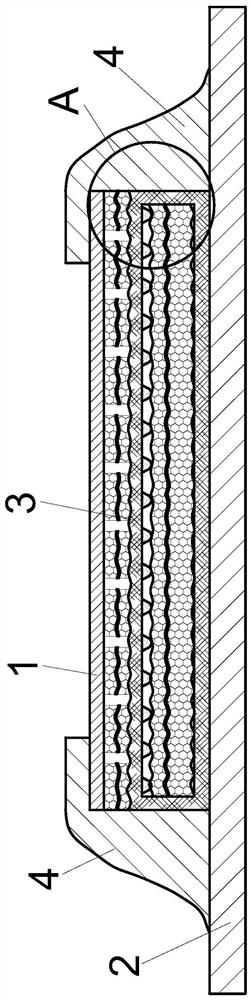

An absorbent product, a disposable technology, applied in the field of sanitary products, can solve the problems of insufficient softness, fiber accumulation, leakage, etc., and achieve the effect of preventing side leakage, relieving stuffy feeling, and being convenient and safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

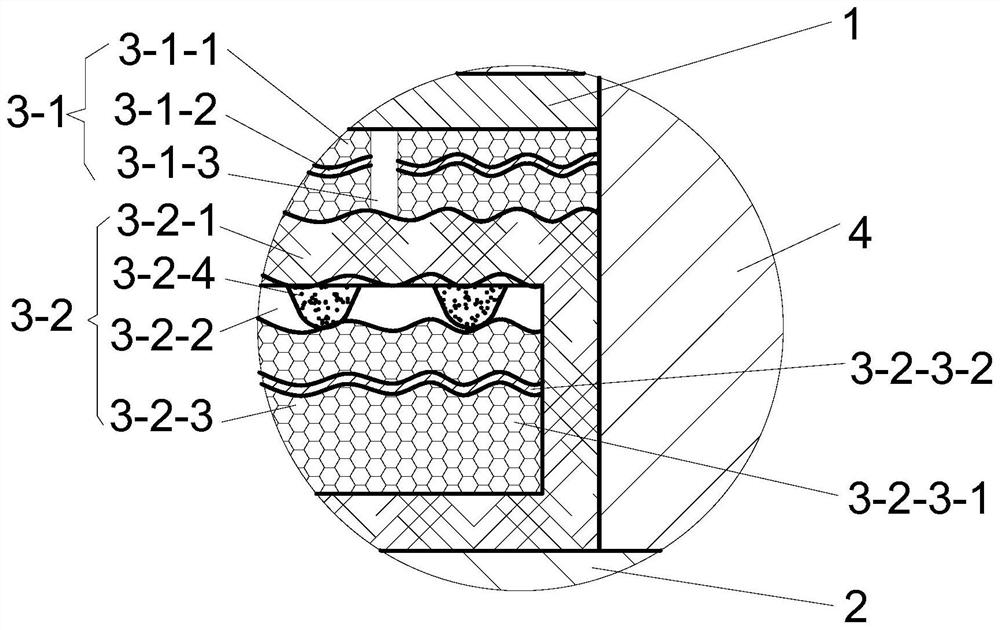

[0053] Top sheet: 35 g / m2 pure cotton perforated non-woven fabric;

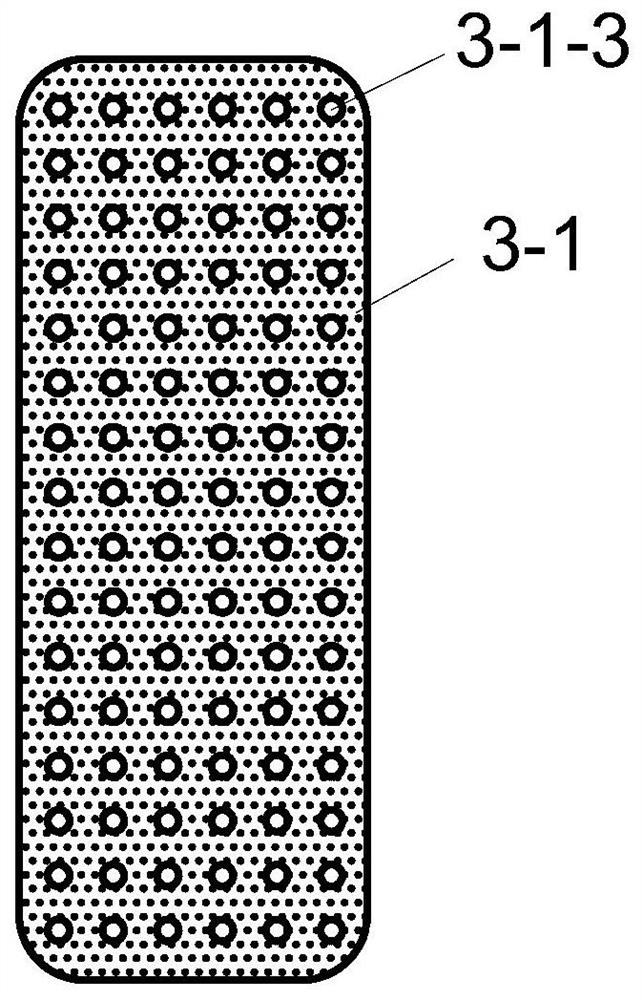

[0054] Upper polyurethane foam layer: 0.5 mm thick, 13 g / m2 SSS non-woven fabric is set in 50 g / m2 polyurethane foam;

[0055] The first outer body: SSS hydrophilic non-woven fabric of 13 grams per square meter;

[0056] Granular layer: SAP granules at 100 g / m2, citric acid granules at 19.2 g / m2, sodium bicarbonate granules at 8.4 g / m2;

[0057] Lower polyurethane foam layer: 2.0 mm thick, specifically: SSS non-woven fabric of 13 g / m2 is arranged in 200 g / m2 polyurethane foam;

[0058] Backsheet: 18 g / m2 PE breathable film;

[0059] Leak-proof bulkhead layer: 15 g / m² spunbonded SMS water-repellent fabric.

[0060] Obtain the performance of absorbent products: saturated absorption of physiological saline: 23 g / g;

[0061] Obtain the performance of the absorbent product: Saturated lock saline: 17 g / g;

[0062] Obtain the performance of absorbent products: saturated artificial plasma absorption: 17 g / g;

...

Embodiment 2

[0066] Top sheet: 23 g / m2 hot-air perforated non-woven fabric;

[0067] Upper polyurethane foam layer 2: 0.5 mm thick, 13 grams / square meter of SSS non-woven fabric is set in the polyurethane foam of 50 grams / square meter;

[0068] The first outer body: SSS hydrophilic non-woven fabric of 13 grams per square meter;

[0069] Granular layer: SAP granules at 80 g / m2, citric acid granules at 19.2 g / m2, sodium bicarbonate granules at 8.4 g / m2;

[0070] Lower polyurethane foam layer 5: 1.0 mm thick, specifically: SSS non-woven fabric of 13 g / m2 is arranged in the polyurethane foam of 100 g / m2;

[0071] Backsheet: 18 g / m2 PE breathable film;

[0072] Leak-proof bulkhead layer: 15 g / m² spunbonded SMS water-repellent fabric.

[0073] Obtain the performance of the absorbent product: saturated absorption of physiological saline: 25 g / g;

[0074] Obtain the performance of the absorbent product: Saturated lock saline: 19 g / g;

[0075] Obtain the performance of absorbent products: satu...

Embodiment 3

[0079] Top sheet: perforated spunbond nonwoven fabric at 13 g / m2;

[0080] Upper polyurethane foam layer: 0.5 mm thick, 13 g / m2 SSS non-woven fabric is set in 50 g / m2 polyurethane foam;

[0081] First outer body: 18 g / m2 toilet paper;

[0082] Granular layer: SAP granules at 70 g / m2, citric acid granules at 19.2 g / m2, sodium bicarbonate granules at 8.4 g / m2;

[0083] Lower polyurethane foam layer: 0.5 mm thick, specifically: SSS non-woven fabric of 13 g / m2 is arranged in 50 g / m2 polyurethane foam;

[0084] Backsheet: 18 g / m2 PE breathable film;

[0085] Leak-proof bulkhead layer: 15 g / m² SMS spunbonded water-repellent fabric.

[0086] Obtain the performance of absorbent products: saturated absorption of physiological saline: 26 g / g;

[0087] Obtain the performance of the absorbent product: Saturated lock saline: 21 g / g;

[0088] Obtain the performance of absorbent products: saturated artificial plasma absorption: 19 g / g;

[0089] Obtain the performance of absorbent produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap