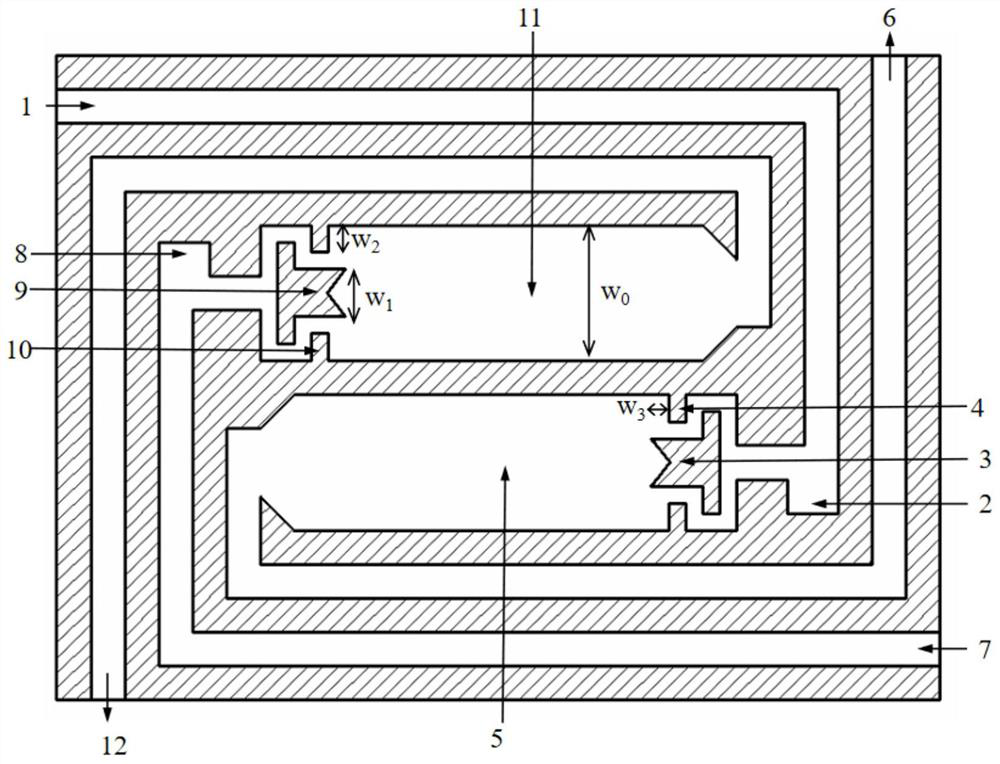

Dual-cavity annular micro burner based on Swiss roll structure

A micro-burner, annular technology, applied in the direction of burners, gas fuel burners, combustion types, etc., can solve the problems of reduced fuel heat release, shortened fuel residence time, increased heat loss, etc., to reduce ignition The required energy, the effect of shortening the ignition delay time, and reducing the exhaust heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

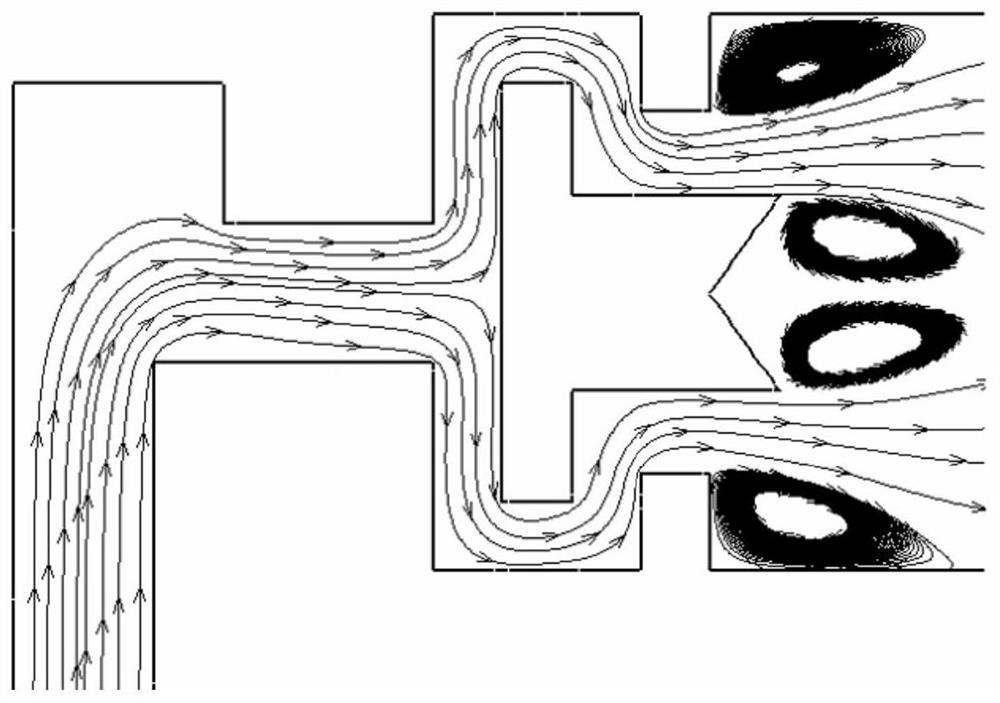

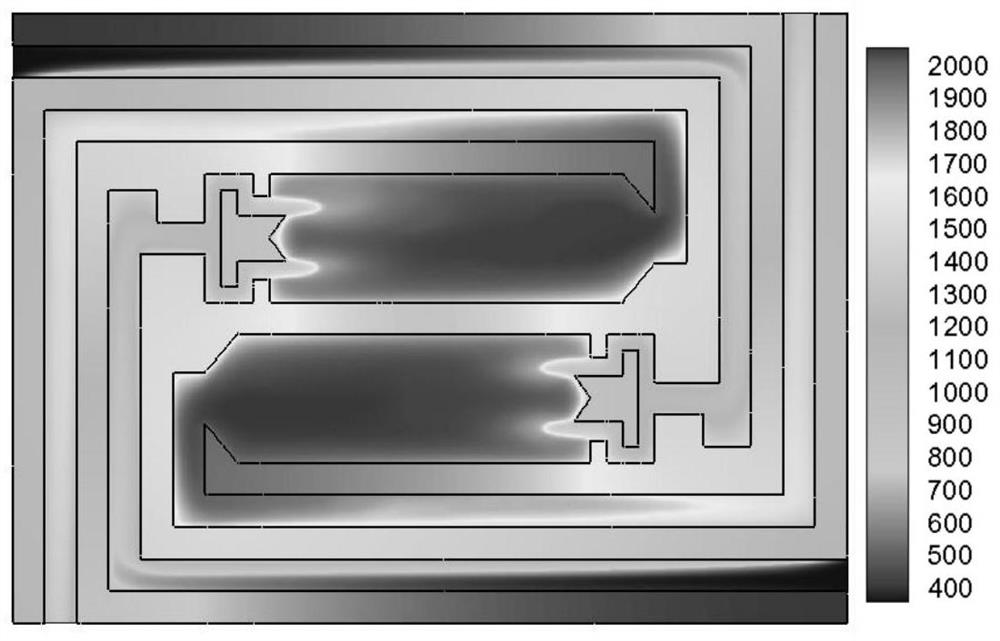

[0032] The methane and air adopt the micro-burner of the pre-mixed combustion method in advance; 0 = 4mm, W 1 = 1.4mm, W 2 = 0.7mm, W 3 =0.5mm; the length of the micro burner is 26mm, the width is 19mm, the solid material is steel, and its density, heat capacity, thermal conductivity and normal emissivity are respectively 8000kg / m 3 , 500J / (kgK), 24W / (m 2 K) and 0.2. Using the fluent numerical simulation method, the detailed methane combustion mechanism (19 steps and 58 primitives) is used to carry out the numerical simulation when the equivalence ratio is 0.5 and the inlet velocity is 10m / s. Such as image 3 As shown, is the cross-sectional temperature field. It can be seen that the gas burns stably in the combustion chamber, the flame anchoring effect is good, and the combustion efficiency can be maintained above 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com