Flow valve, liquid rocket fuel supply system and liquid rocket

A liquid rocket and flow valve technology, applied in the field of hydraulic valves, can solve problems such as poor stability, achieve stable fluid supply, increase sealing performance, and prevent liquid leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

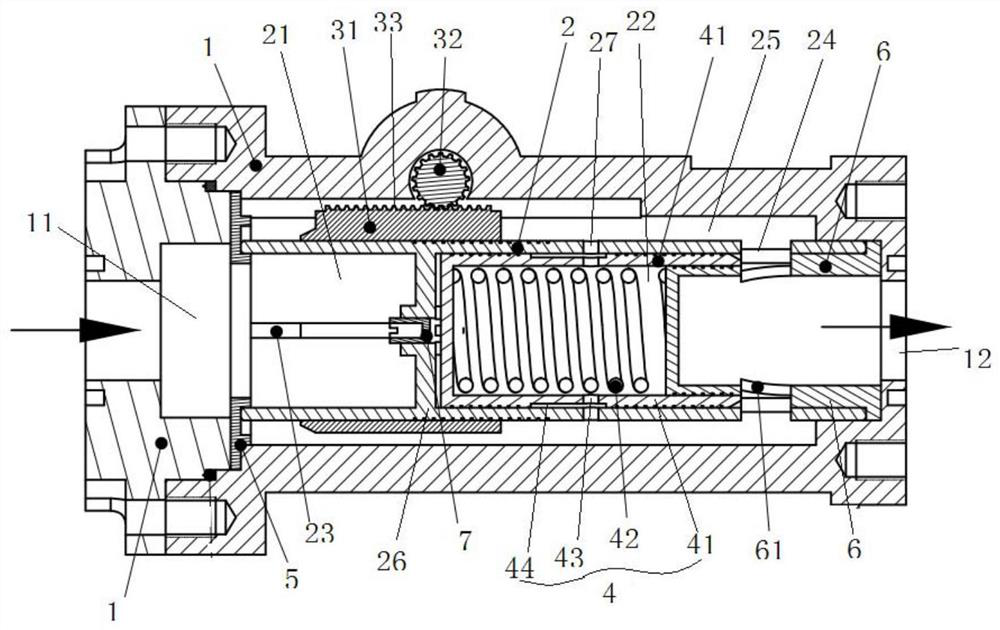

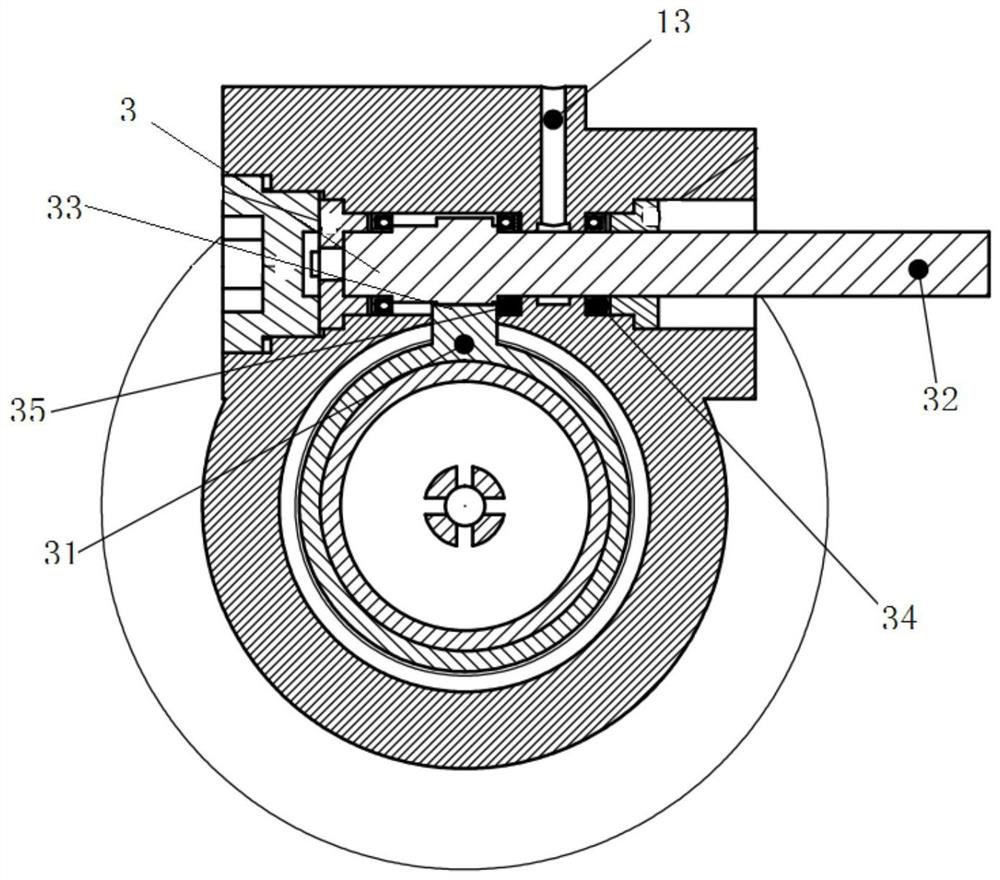

[0044] Such as Figure 1 to Figure 2 As shown, it is a flow valve provided by this embodiment, which is specifically used on a liquid rocket engine to adjust the reaction amount of liquid oxygen and methane in the liquid rocket engine, so as to realize the adjustment of the thrust of the engine.

[0045] Such as figure 1 As shown in , the flow valve includes a valve body 1, the valve body 1 is a hollow structure, and the accommodating space formed inside it is cylindrical, and the two ends of the internal space are respectively provided with an inlet 11 and an outlet 12. The medium, such as liquid oxygen or methane, flows into the flow valve in this embodiment through the inlet port 11 . In order to cooperate with the outside world, relevant joint structures can be designed at the inlet port 11 and the outlet port 12 to realize the convenience of connection.

[0046] The valve body 1 is embedded with a valve sleeve 2, which is also a hollow structure, specifically a thin-wal...

Embodiment 2

[0067] This embodiment provides a liquid rocket feeding system, including the above-mentioned flow valve, which has all the technical advantages of the flow valve in the above-mentioned embodiment 1, and will not be repeated here.

[0068] The liquid rocket feeding system includes a fuel supply pipeline and a catalyst supply pipeline, and a flow valve is installed on the above pipeline to control the flow supplied by the fuel supply pipeline and the catalyst supply pipeline to the combustion chamber of the engine, so as to ensure that the engine generates thrust stability.

Embodiment 3

[0070] This embodiment provides a liquid rocket, including the liquid rocket feeding system in Embodiment 2 above, and has all its technical advantages, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com