A kind of preparation method of polyethersulfone resin

A technology of polyethersulfone resin and polymer solution, applied in the field of polymer synthesis, can solve the problems of difficult polymerization reaction, dark product color, long polymerization cycle, etc. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

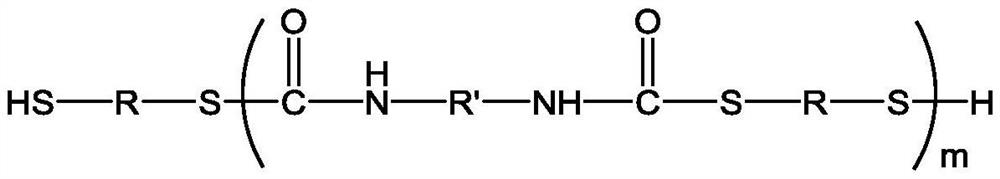

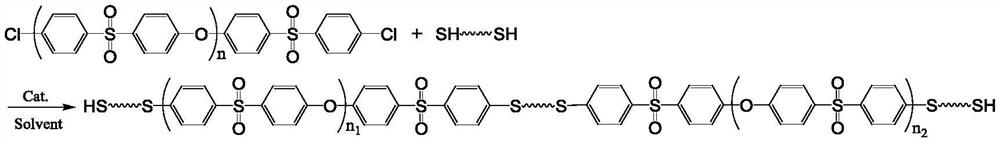

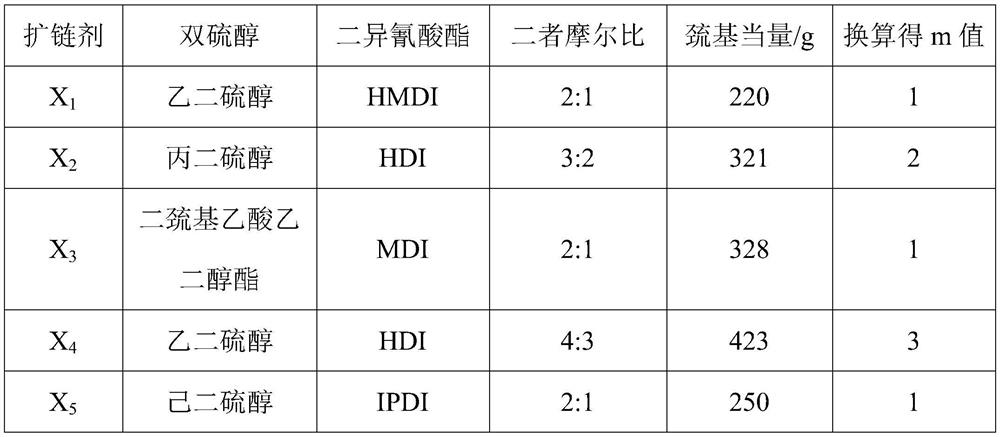

[0066] Preparation of chain spreaders

[0067] In a four-mouth flask with nitrogen and a reflux water separator, 18.9g of ethylene disultanol was dissolved in 200ml of butanone distilled water, fully dissolved and heated up to 65 ° C, slowly added 26.2g dicyclohexylmethane diisocyanate, the control temperature gradually warmed up to reflux, reaction 2h, cooling after the product precipitated, after filtering with acetone washed 2 times after vacuum drying, to obtain the target bispoyl compound (chain extender X). 1 37.5g, yield 83.2%. The compound was tested for a thiol equivalent of 220, and after conversion, it was learned that the number of repeating units was about 1, that is, m = 1.

[0068] By selecting different types of dithiols and diisocyanates, or adjusting the reaction molar ratios of dithitols and diisocyanates (see Table 2 for details on the preparation of chain spreaders), different structures and different thiol equivalents can be prepared, and the remaining condit...

Embodiment 1

[0072] In a four-mouth flask connected to a condensing tube, water separator, mechanical agitator and thermometer, 93 g of molecularly sieve-dewatered N, N-dimethylacetamide (moisture content 1 Pd / C catalyst 0.029g, reacted at residual temperature (about 135 °C) for 2h to give a polymer solution. Under the condition of high-intensity stirring, the polymer solution was poured into 250ml of water for precipitation, filtered and then boiled for 3 to 4 times, and dried at 180 °C in a vacuum oven for 6h to obtain a finished polyethersulfone resin product of 45.2g.

Embodiment 2

[0074] In the reactor connected to the reflux condensing device, 1195.5g of dichlorodiphenyl ether, 855.26g of potassium carbonate, 1238.96g of bisphenol S, 3749g of N, N-dimethylformamide and 1874g of toluene were added to the reactor, the air in the kettle was extracted to negative pressure, and then nitrogen was introduced to completely replace the air in the kettle; the temperature in the kettle was heated to 110 ~ 112 ° C, and the constant temperature reaction was maintained for 1 hour, and the toluene reflux was maintained until all the generated water was brought out. Toluene is then distilled, heating is stopped, and the reaction solution is cooled to room temperature (25 °C). Continue to pour 198.3 g of chain spreader X into the reactor 2 and 3.587g of copper acetylacetonate, stirred the reaction for 1h to give a polymer solution. Under high-intensity stirring conditions, the polymer solution was precipitated with 9000g methanol, and then washed with water 3 times repeate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com