Distribution equipment for tuna cold chain logistics

A technology for cold chain logistics and tuna, which is applied in the field of distribution equipment for tuna cold chain logistics, can solve the problems of difficulty in taking out vacuum sterilization, affecting meat quality and appearance, and tuna freshness preservation, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

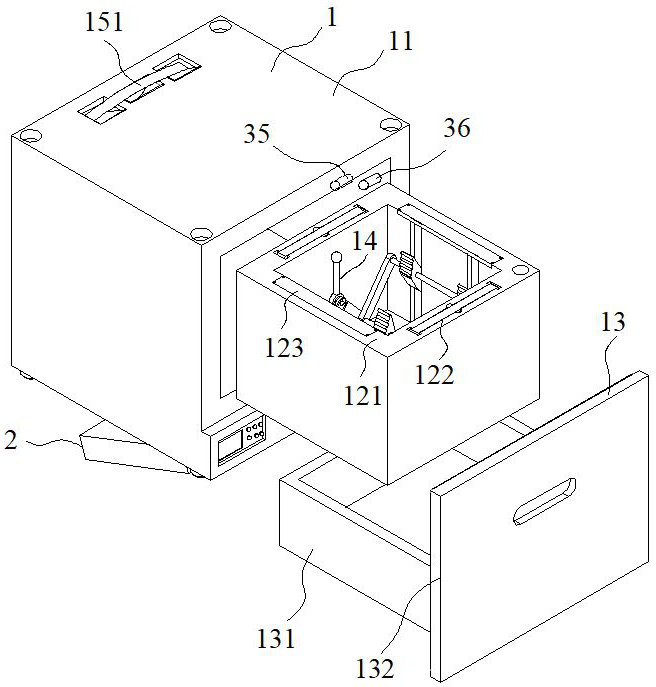

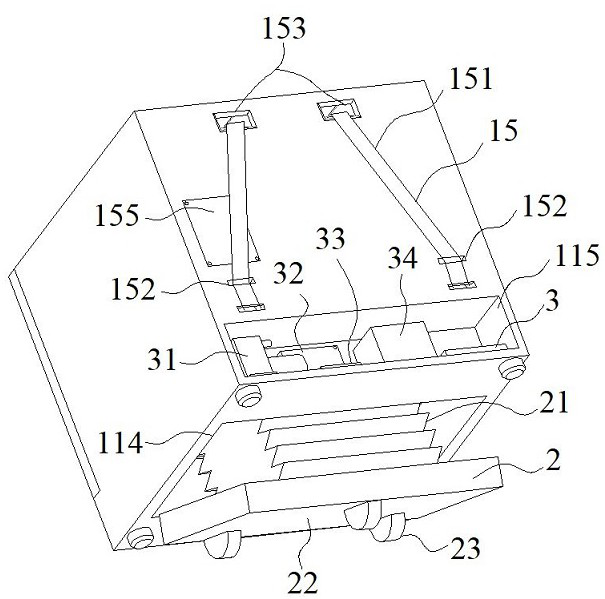

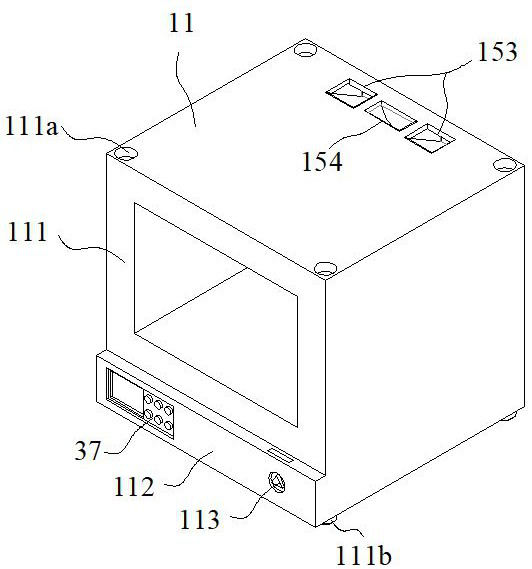

[0036] Such as Figure 1-9 As shown, the distribution equipment used for tuna cold chain logistics includes a distribution box 1 and a moving mechanism 2. The moving mechanism 2 is located at the bottom of the distribution box 1. The distribution box 1 includes a main box 11 with an opening on one side and a main box connected to the main box. Body 11 is slidably connected to the sliding door 13 for sealing; the upper surface of the main box body 11 and the opposite side of the opening side are provided with a carrying mechanism 15; the opposite side of the main box body 11 opening side is also provided with a control mechanism 3, and the control mechanism The air path of 3 leads to the sealed space formed by the main box 11 and the drawing door 13 and the moving mechanism 2; the drawing door 13 can be built with a cold storage body 12 filled with cold storage materials and used to store and transport items; the cold storage body 12 A height-adjustable adjustment mechanism 14 ...

Embodiment 2

[0056] When the distribution equipment for tuna cold chain logistics of the present invention is actually used, when transporting items, the drawing door 13 is opened to move the cold storage body 12 frozen in the cold storage to the carrying box 131 . Adjust the adjustment handle 146 to spread the first connecting rod 141 and the second connecting rod 142 to push the horizontal side roller 145a to slide to both sides, and turn the inclined side of the support block 145b on the horizontal side toward the oblique upward direction to open the space for placing items in the adjustment mechanism. Place the transported items on the horizontal side bracket 145b, and under the action of gravity, the horizontal side bracket 145b gradually becomes horizontal and drives the vertical side bracket 145b to reverse, and is driven by the spring connected by the first connecting rod 141 and the second connecting rod 142 The roller 145a moves until the inclined side of the vertical side support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com