Candy packaging machine

A packaging machine and candy technology, applied in the field of candy packaging, can solve the problems of inability to package box decoration and packaging, and achieve the effect of improving printing packaging efficiency and fast printing packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

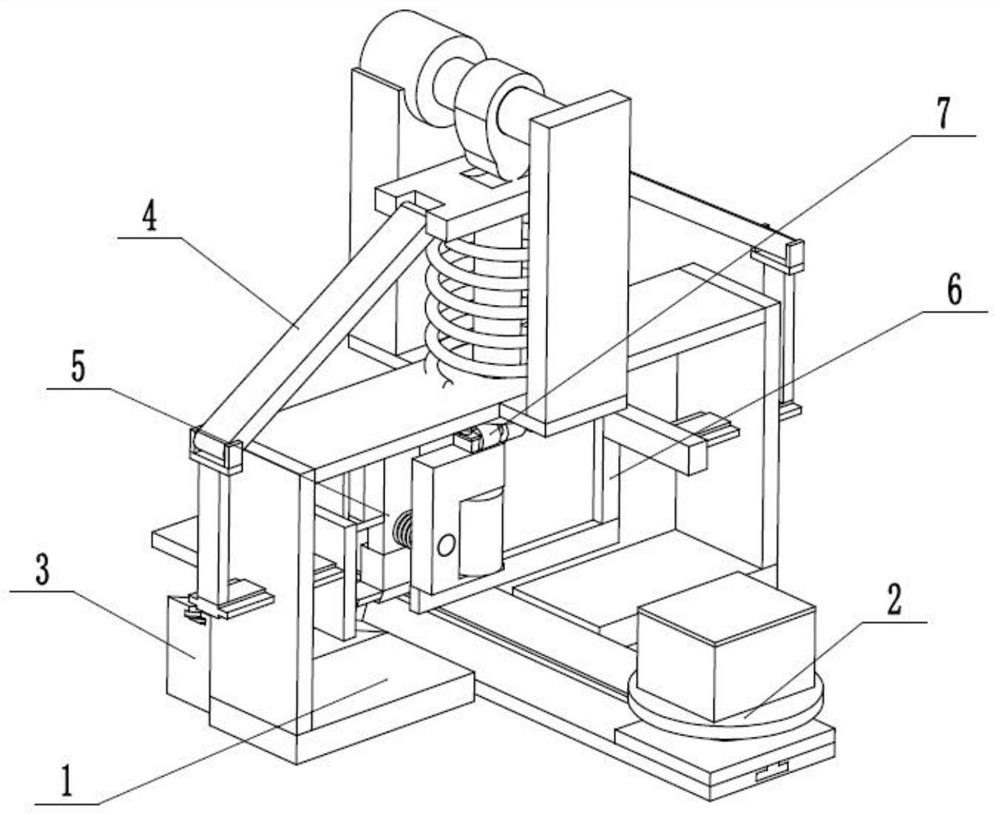

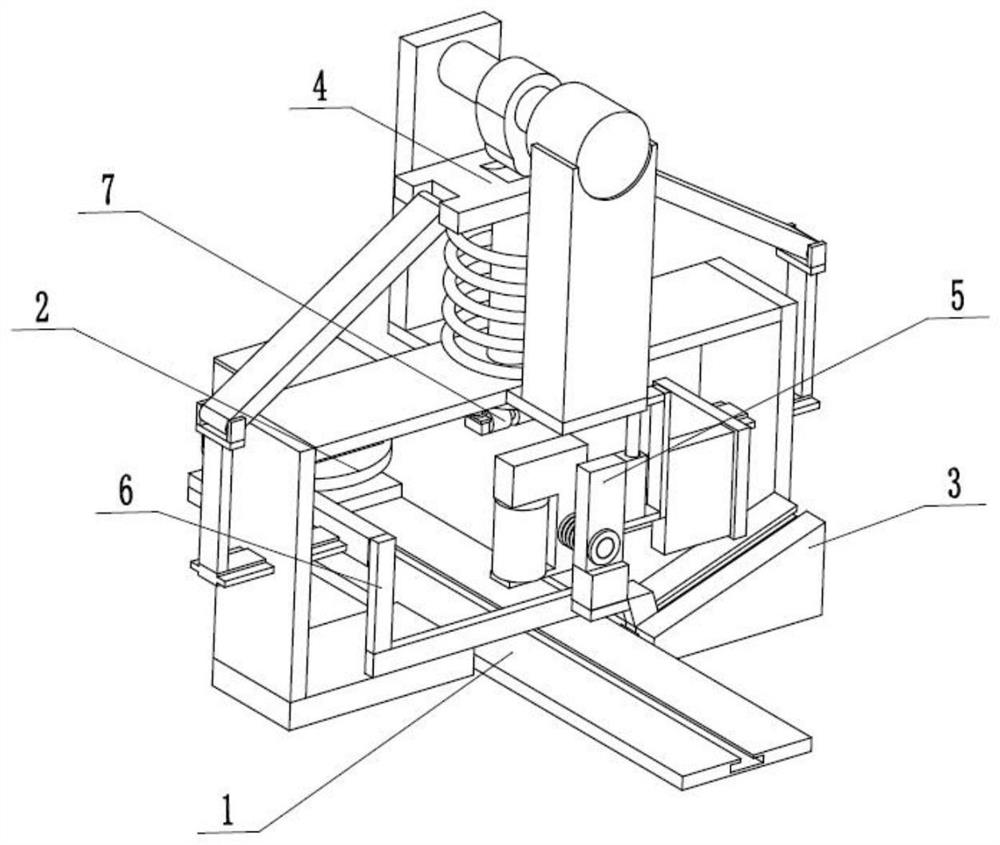

[0029] Such as Figure 1 to Figure 9 As shown, a candy packaging machine includes a packaging frame 1, a transport carrier 2, a limit ramp seat 3, a combined driver 4, a side packaging printer 5, an L-shaped driving rack 6 and an upper surface printer 7. The above-mentioned transport carrier 2 is horizontally slidably connected to the packaging frame 1, the transport carrier 2 is engaged with the L-shaped driving rack 6 for transmission, the limit ramp seat 3 is fixedly connected to the packaging frame 1, and the combined drive 4 is slidably connected In the packaging frame 1, the side packaging printer 5 and the L-shaped driving rack 6 are respectively fixedly connected to the two ends of the inner wall of the combination driver 4, and the side packaging printer 5 is slidably connected to the limit slope seat 3, and the upper end surface printer 7 is fixedly connected to the lower end of combination driver 4. Place the box to be printed and packaged on the transport carrier ...

specific Embodiment approach 2

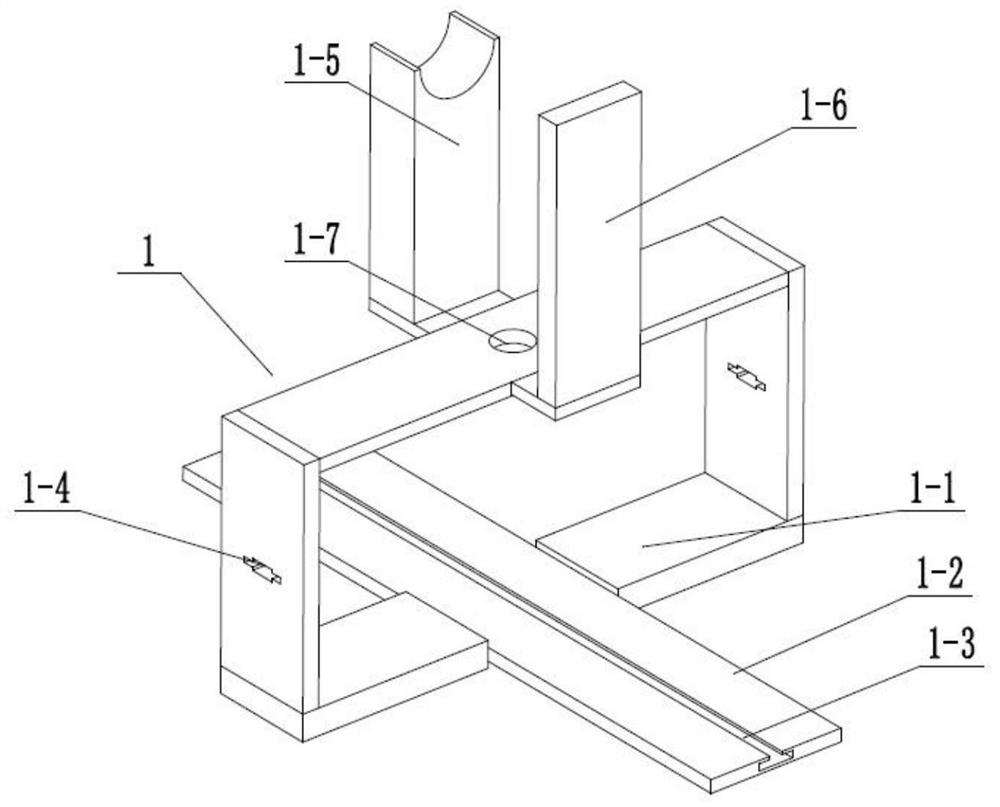

[0031] Such as Figure 1 to Figure 9As shown, this embodiment will further explain Embodiment 1. The packaging frame 1 includes a frame frame 1-1, a horizontal fixed slide plate 1-2, a horizontal chute 1-3, and two limiting inner chute 1 -4, motor fixing seat 1-5, fixed rotating seat 1-6 and center turning hole 1-7, horizontal fixed slide plate 1-2 is fixedly connected in the frame frame 1-1, and horizontal chute 1-3 runs through and is arranged on On the horizontally fixed slide plate 1-2, two limiting inner chute 1-4 respectively run through the two ends of the frame frame 1-1, and the motor fixing seat 1-5 and the fixed rotating seat 1-6 are fixedly connected on the On the upper end of the frame frame 1-1, the central turning hole 1-7 is arranged at the center of the upper end of the frame frame 1-1.

specific Embodiment approach 3

[0033] Such as Figure 1 to Figure 9 As shown, this embodiment will further illustrate the second embodiment. The transport carrier 2 includes an intermittent drive slide 2-1, a lower slider 2-2, a loading shaft 2-3, an engaging gear 2-4, Loading turntable 2-5 and fixed plug 2-6, the lower end of intermittent driving slide seat 2-1 is slidably connected in the transverse chute 1-3 through lower block 2-2, and load shaft 2-3 is rotationally connected in the intermittent On the drive slide 2-1, the connecting gear 2-4 and the loading turntable 2-5 are all fixedly connected on the loading rotating shaft 2-3, and the fixed plug 2-6 is fixedly connected on the loading rotating disk 2-5. The candy box to be printed and packaged is placed on the fixed insert 2-6; the drive intermittently drives the slide 2-1 to move in the horizontal fixed slide 1-2 through the lower slide 2-2 until the gear 2-4 is connected with the L-shaped drive The tooth bar 6 is in contact with each other and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com