Automatic positioning and trimming equipment

An automatic positioning and trimming technology, used in household components, other household appliances, household appliances, etc., can solve the problems of low port trimming efficiency, plastic port knife marks, and high trimming efficiency, saving labor costs and repairing. High edge efficiency and good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

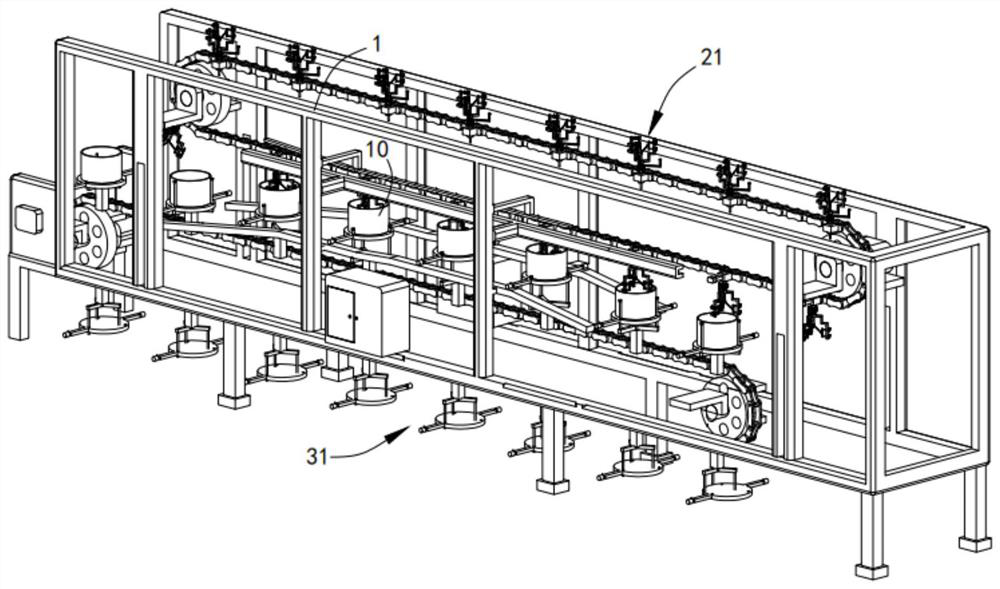

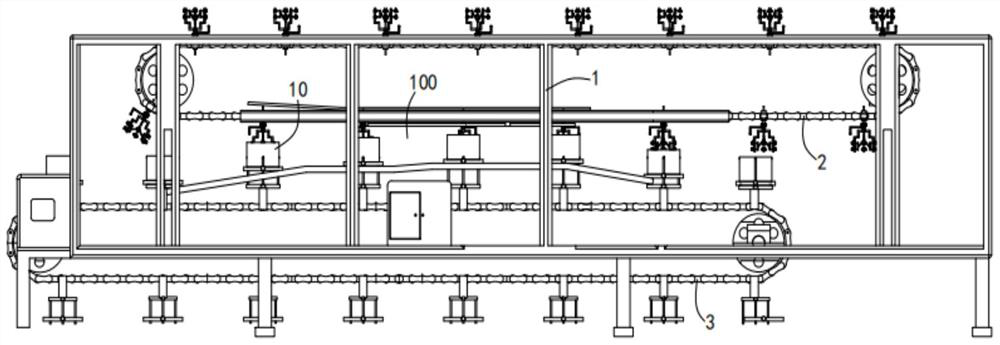

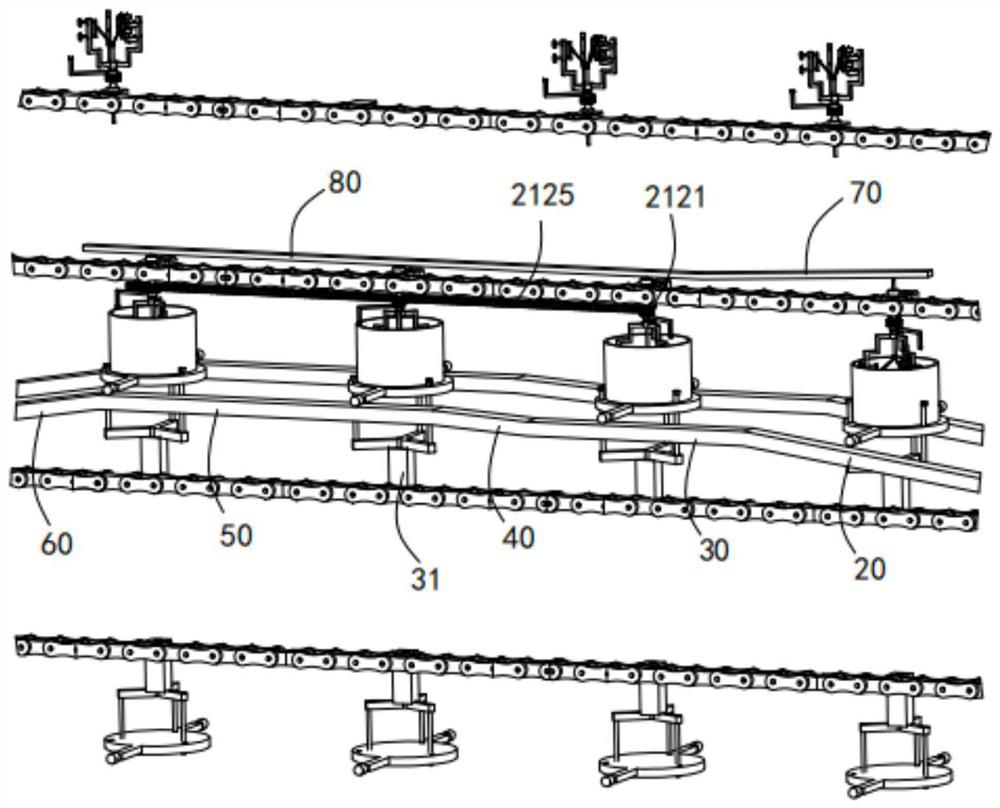

[0037] Such as Figure 1 to Figure 9 As shown, an automatic positioning and trimming equipment includes a frame 1 and a first rotary chain 2 and a second rotary chain 3 arranged on the frame 1, and the first rotary chain 2 and the second rotary chain 3 are arranged up and down , the first rotary chain 2 is provided with a number of trimming mechanisms 21 in an array, and the second rotary chain 3 is provided with a number of support mechanisms 31 in an array;

[0038] A trimming channel 100 is formed between the first rotary cha...

Embodiment 2

[0052] Such as Figure 6 and Figure 8 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that: the side of the fixed seat a22 is fixedly connected with a guide limit block 6, and a guide limit bar 7 fixed on the frame 1 is arranged above the trimming channel 100, and the guide limit bar 7 The side of 7 is provided with a guide limit groove 71, and the guide limit block 6 slides along the guide limit groove 71.

[0053] In this embodiment, by setting the guide limit block 6 to slide along the guide limit groove 71, the stability of the trimming mechanism is ensured during the clamping and rotating trimming process, and the trimming mechanism is prevented from being tilted and affecting the trimming quality. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com