A device for punching holes in concrete walls

A drilling device and concrete technology, applied in the direction of working accessories, manufacturing tools, stone processing tools, etc., can solve the problems of irregular orbit of electric drill, cumbersome and inconvenient operation process, and the opening of round holes is not a perfect circle, etc., so as to simplify drilling Operation process, avoiding irregular openings, and optimizing the effect of linkage structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

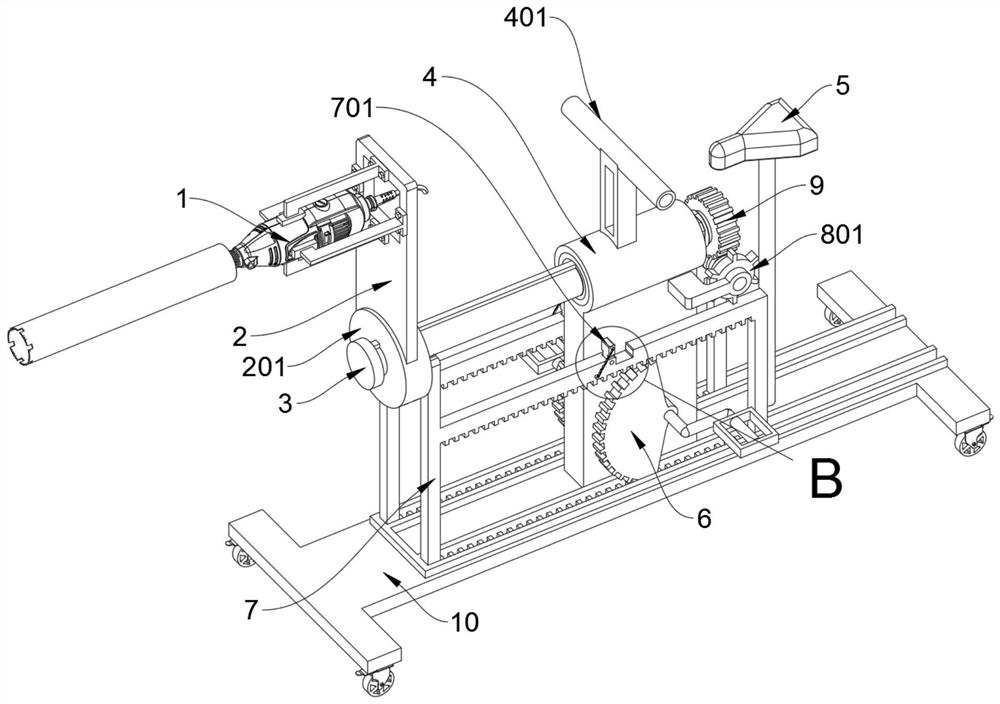

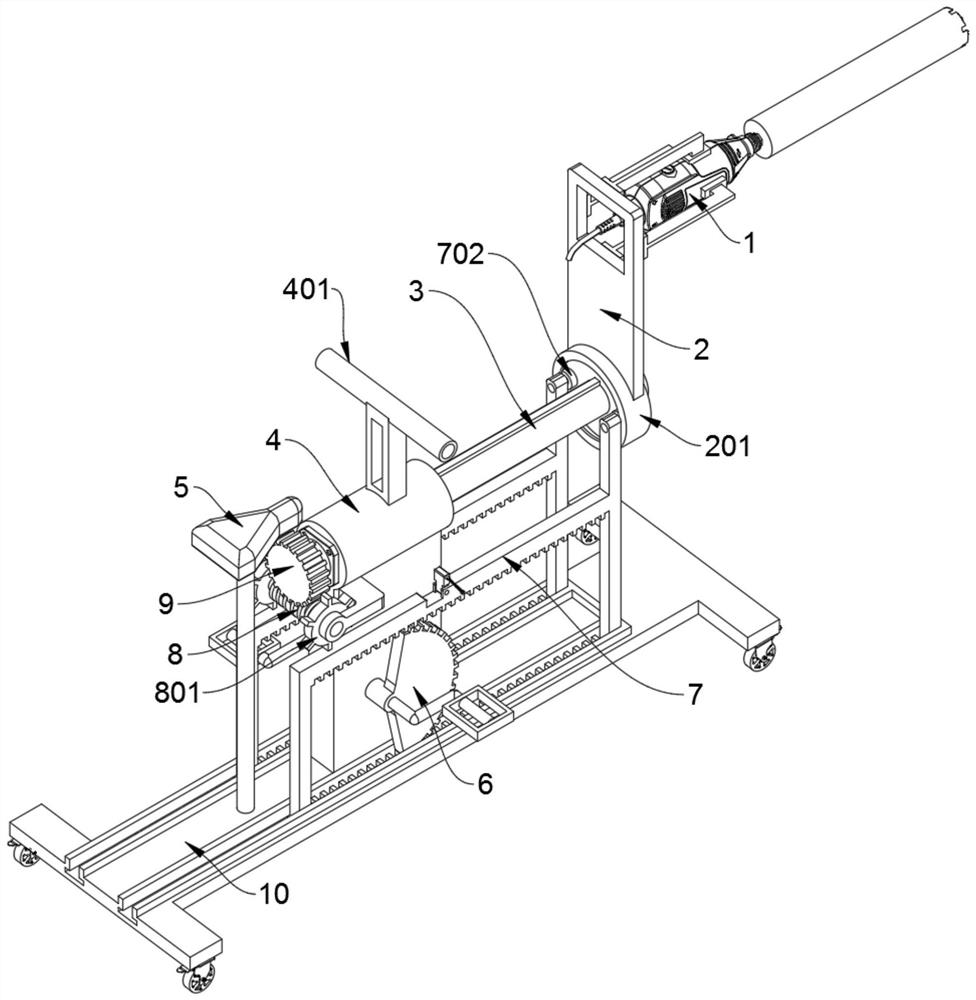

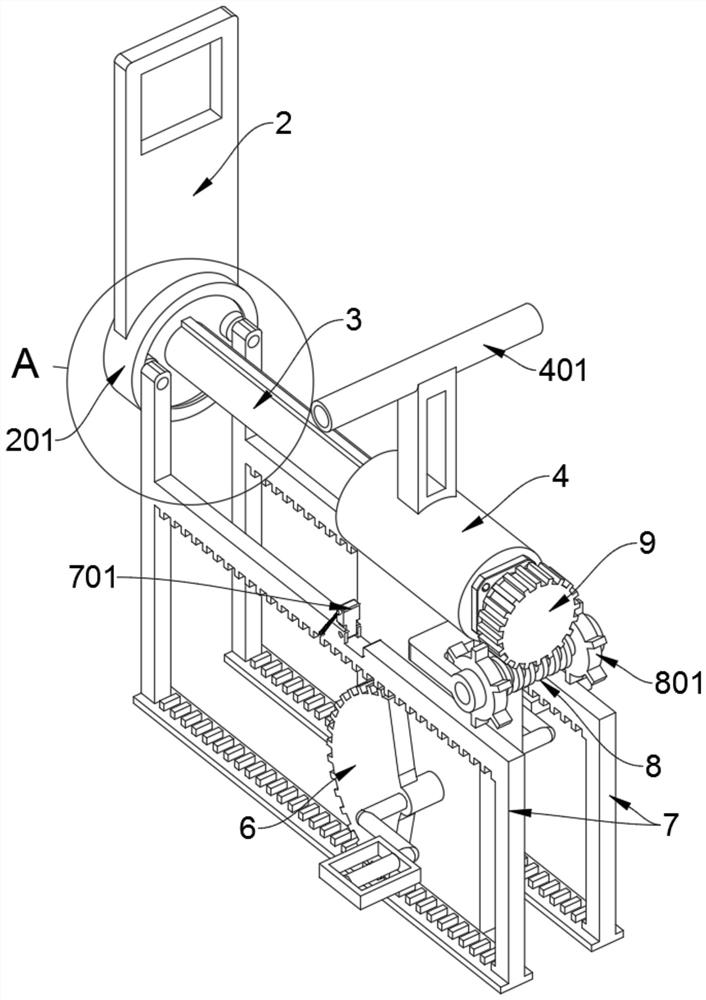

[0030] see Figure 1 to Figure 6 and Figure 8 , an embodiment provided by the present invention: a concrete wall punching device, including a mounting plate 2, a supporting shaft 3, a positioning sleeve 4, a push frame 7 and a base 10, the top end of the mounting plate 2 faces upwards An electric drill 1 is installed in the front lock; the mounting plate 2 includes a swivel 201 and an annular baffle 202, and a swivel 201 is welded and fixed at the bottom of the mounting plate 2, and the swivel 201 is slipped on the supporting shaft 3 and connected by a key transmission, and the rear side of the swivel 201 is welded with an annular baffle 202, through the swivel 201, the mounting plate 2 can drive the electric drill 1 to slide back and forth along the supporting shaft 3 for drilling; the second half of the supporting shaft 3 rotates and wears On the positioning sleeve 4, a worm gear 9 is set on the rear end of the supporting shaft 3; a vehicle seat 5 is installed on the upper...

Embodiment 2

[0033] On the basis of Example 1, please refer to Figure 4 , Figure 7 and Figure 9 , an embodiment provided by the present invention: a concrete wall punching device, which also includes a push frame 7, and the two push frames 7 are placed in two T-shaped positions on the base 10 correspondingly sliding left and right. In the chute, the push frame 7 includes a top block 701 and a guide wheel 702, and the middle section at the top of the two push frame 7 is provided with a placement groove, and the two push blocks 701 are erected on the two sides with respect to the spring pull rotation. Place in the slot; the tops of the two push frame 7 front side vertical struts are all rotatably equipped with a guide wheel 702.

[0034] Further, the inner sides of the upper and lower side bars of the two pushing frames 7 protrude to support a row of positioning teeth, and the two bevel gears 6 can alternately rotate and mesh corresponding to the upper and lower rows of positioning teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com