Automatic roast sausage stringing equipment

A sausage roasting and equipment technology, which is applied in meat processing equipment, slaughtering, food science, etc., can solve the problems of time-consuming, labor-intensive, finger pricking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

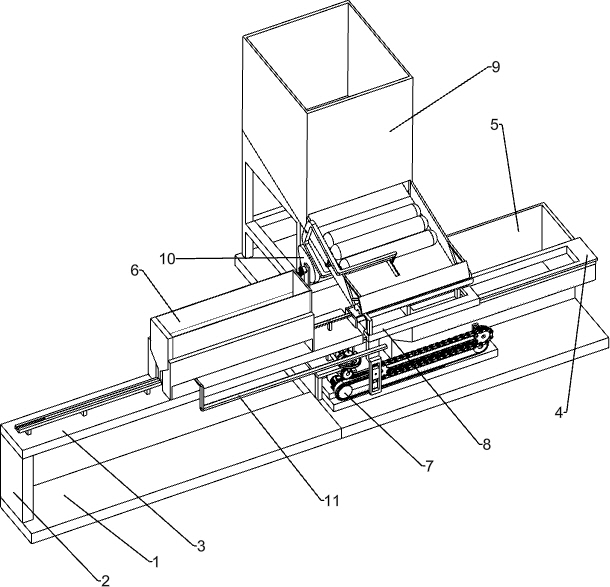

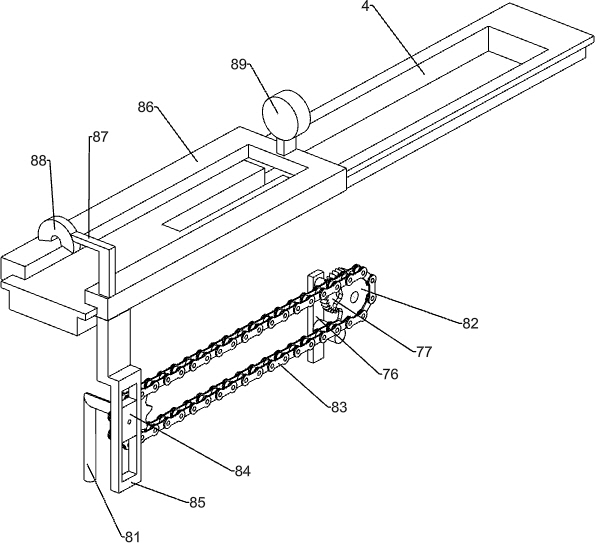

[0028] An automatic skewer sausage equipment, such as Figure 1-5 As shown, it includes a bottom plate 1, a side plate 2, a placement plate 3, a drain plate 4, a collection frame 5, a penetration assembly 6 and a drive assembly 7. The top left side of the bottom plate 1 is connected to the side plate 2, and the top of the side plate 2 is connected to the There is a placement plate 3, the right side of the placement plate 3 is connected with a leaking plate 4, the bottom of the draining plate 4 is connected with a collection frame 5, the top of the placement plate 3 is installed with an insertion assembly 6, and the top right of the bottom plate 1 is installed with a drive assembly 7. A reciprocating assembly 8 is installed on the drain plate 4 .

[0029] The insertion assembly 6 includes a placement frame 61, a signing box 62, a support block 63, a square guide groove 64, a push rod 65, a push handle 66, a circular guide groove 67 and a material trough 68, and the front and re...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 and Figure 6 As shown, also includes blanking assembly 9, and blanking assembly 9 includes bottom frame 91, material box 92, material guide plate 93, material resisting plate 94, intermittent material blocking frame 95 and spring 96, the rear side of collecting frame 5 Base plate 1 top is connected with chassis 91, and the top of chassis 91 is connected with material box 92, and the front side lower part of material box 92 is connected with material guide plate 93, and the front side of material guide plate 93 is connected with material-resisting plate 94, and material guide The left side of the plate 93 is rotatably connected with an intermittent material retainer 95 , and a spring 96 is connected between the intermittent material retainer 95 and the material guide plate 93 .

[0035] A large amount of grilled sausages are manually put into the material box 92, and the grilled sausages slide out on the material guide plate ...

Embodiment 3

[0039] On the basis of Example 2, such as figure 1 , Figure 8 and Figure 9 As shown, a linkage assembly 11 is also included, and the linkage assembly 11 includes an arc rack 111, a bevel gear 112, a third rotating shaft 113, a fixed frame 114, a gear plate 115, a linkage gear 116, a rotating rod 117, and a transmission gear 118 , double gear 119, fixed rod 1110 and long rack 1111, the front side of rotating gear 104 is connected with arc-shaped rack 111, and the bottom right side of placing plate 3 is connected with fixed mount 114, and the bottom rotational type of fixed mount 114 is connected with The third rotating shaft 113, the bottom end of the third rotating shaft 113 is connected with a bevel gear 112, the bevel gear 112 meshes with the arc rack 111, the top of the third rotating shaft 113 is connected with a gear plate 115, and the upper part of the fixed frame 114 is rotating Connected with a rotating rod 117, the bottom end of the rotating rod 117 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com