Method for measuring dust concentration at deduster inlet

A technology of dust concentration and dust collector, applied in the environmental protection field of coal-fired power plants, can solve problems such as increasing test errors, and achieve the effects of extending the load time period, reducing test costs, and improving the level of environmental protection technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following is an example of dust concentration test at the dust collector inlet of a boiler under low and medium load.

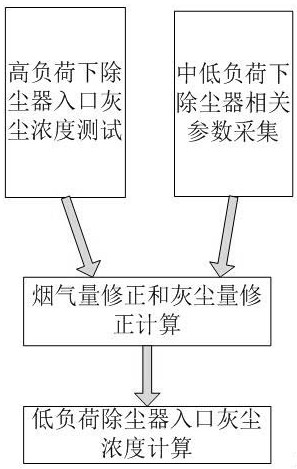

[0054] A boiler is tested for the dust concentration of the dust collector on the A side. The overall process of the test is shown in the appendix figure 1 ,include:

[0055] ① Dust concentration test at the inlet of the dust collector under high load.

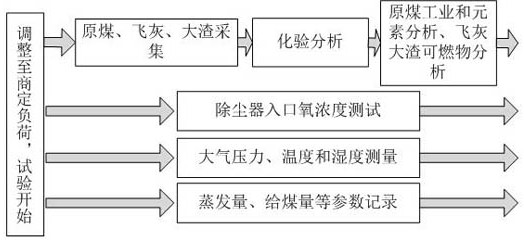

[0056] ② Collection of relevant parameters of the dust collector under low and medium loads.

[0057] ③ Flue gas volume correction and dust volume correction calculation. The amount of flue gas and dust is corrected according to the relevant parameters of the dust collector under low and medium loads and the dust test results at the inlet of the dust collector under high loads.

[0058] ④ Calculation of the dust concentration at the inlet of the low-load dust collector.

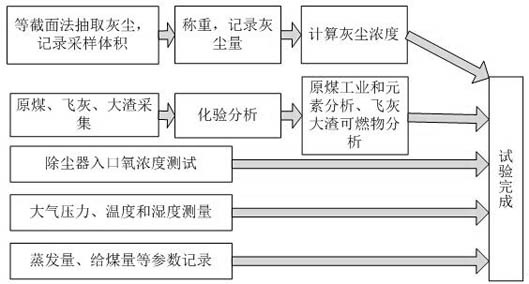

[0059] The test procedure of the dust concentration at the inlet of the dust collector under high load is shown in the attac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com