A method and system for measuring the thickness of multi-size workpieces based on machine vision

A machine vision and thickness measurement technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of inflexible measurement, low measurement accuracy, easy to damage workpieces, etc., to improve measurement, high flexibility, and reduce measurement costs. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

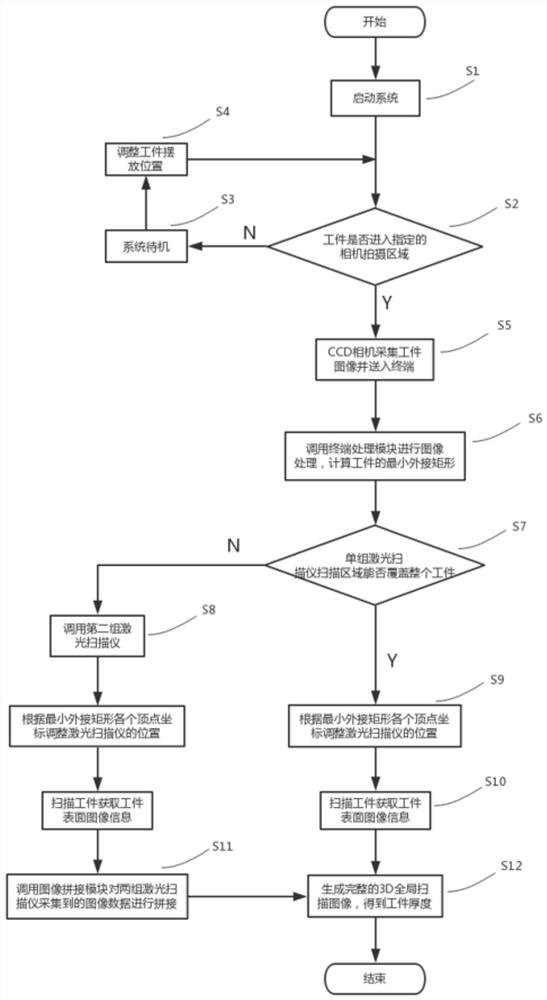

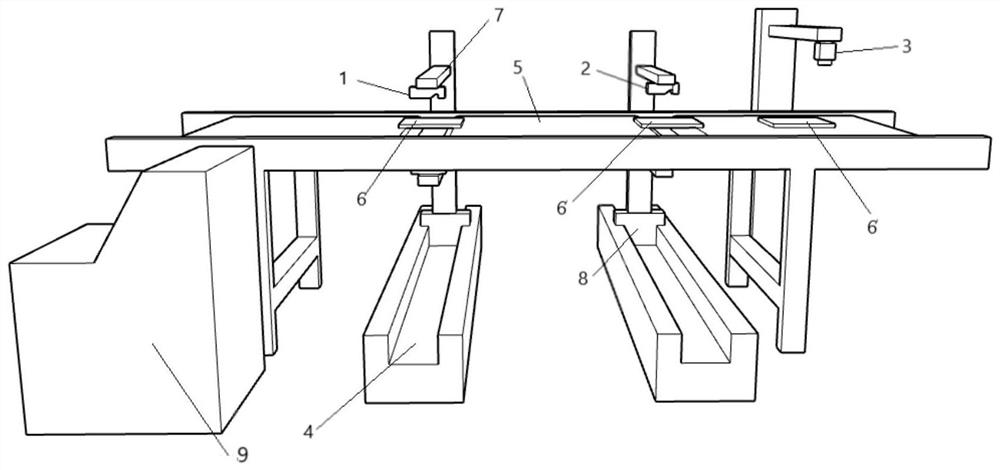

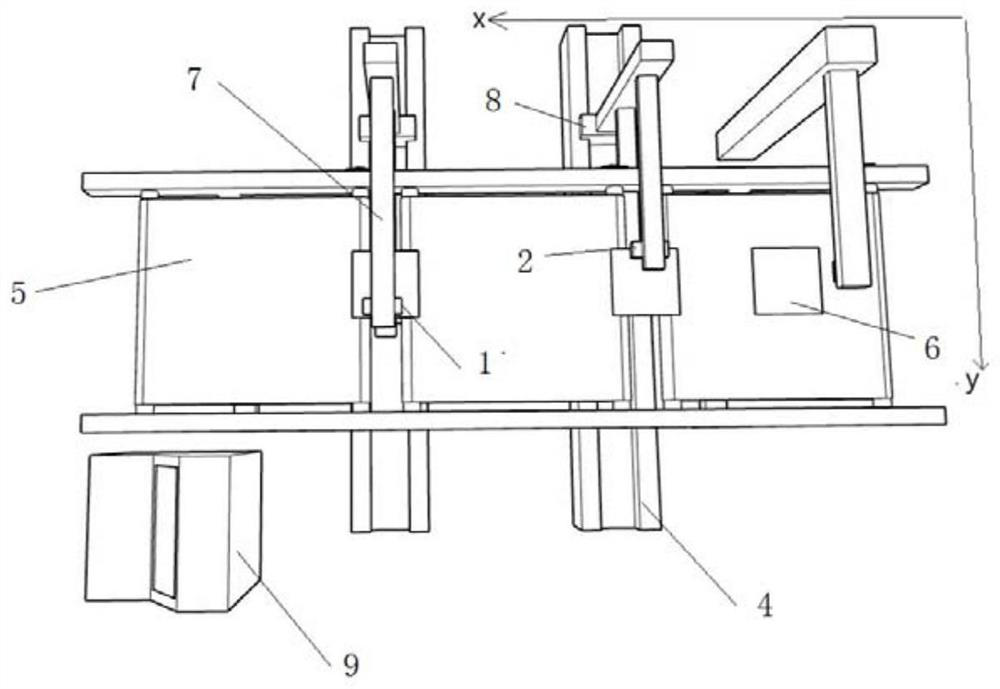

[0052] The invention provides a multi-size workpiece thickness measurement system based on machine vision, which can measure 1 *L 2 Within, the thickness of the workpiece within W thickness measurement (L 1 is the scanning area width of the laser scanner, L 2 is the length of the conveyor belt, W is the measurement range of the laser scanner). The measurement system consists of a data processing terminal, a workpiece detection unit, an image acquisition unit, and a control unit. The image acquisition unit has two cascaded scanner groups. When the scanning area of the first-stage laser scanner group can cover the entire workpiece, only the first stage is activated. When the scanning area of the first-stage laser scanner group cannot cover the entire workpiece start the second stage. According to the selected laser scanner installation distance (CD), m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com