An energy-saving and environment-friendly heat exchanger with high thermal efficiency

An energy-saving, environmental-friendly, thermal-efficiency technology, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of increasing the labor intensity of the staff and reducing the efficiency of maintenance, so as to save maintenance time, Improve the efficiency of disassembly and avoid damage to the head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

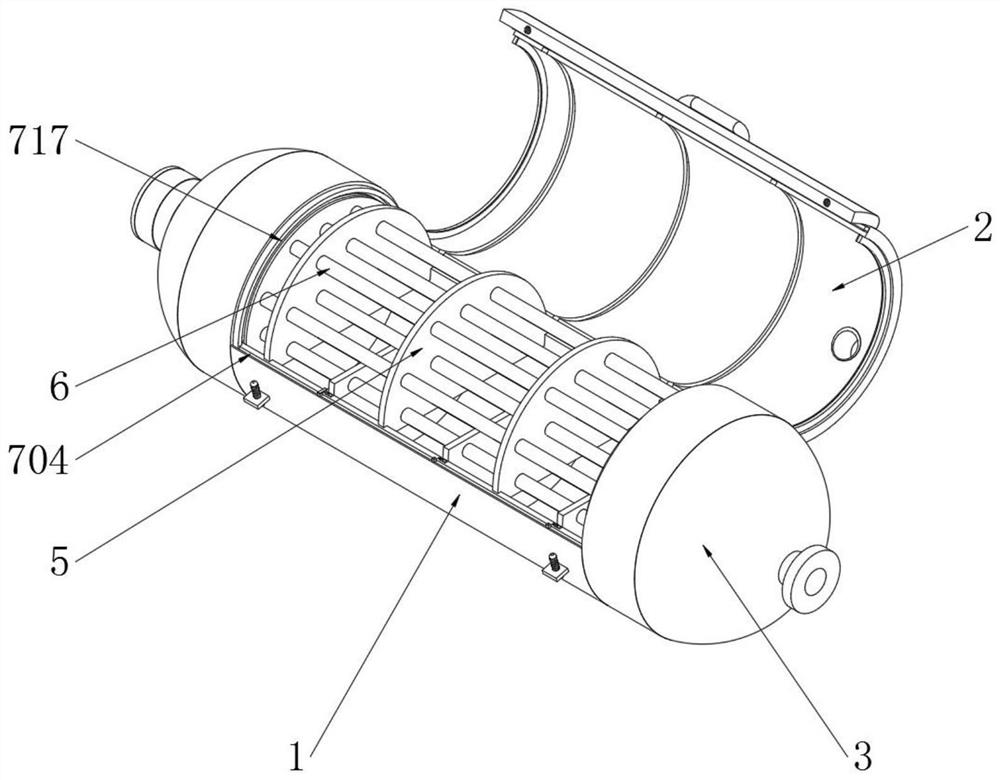

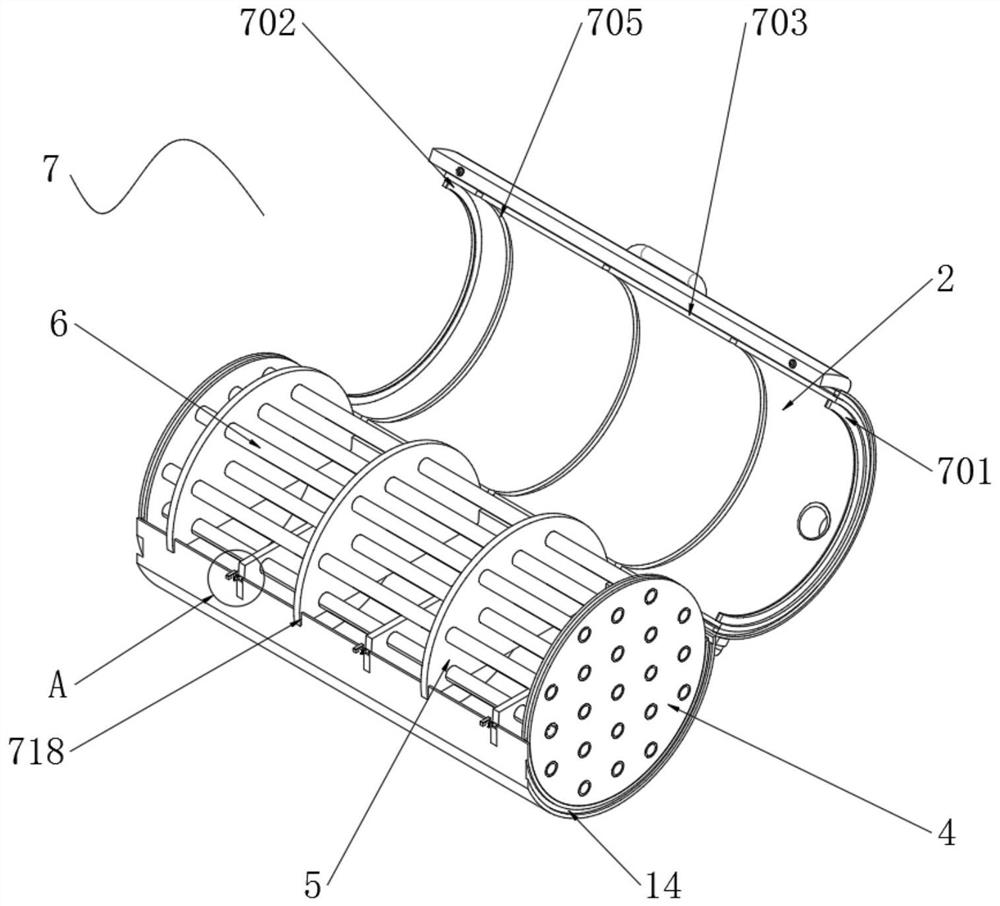

[0046] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, an energy-saving and environment-friendly heat exchanger with high thermal efficiency, comprising a shell 1, one end of the shell 1 is hinged with a shell cover 2, both ends of the shell 1 are installed with tube sheets 4 through screws, and the shell 1 A deflection baffle 5 is evenly placed inside, a head 3 is installed on both ends of the shell 1 through a screw, and a water pipe 6 is evenly installed between the two tube sheets 4;

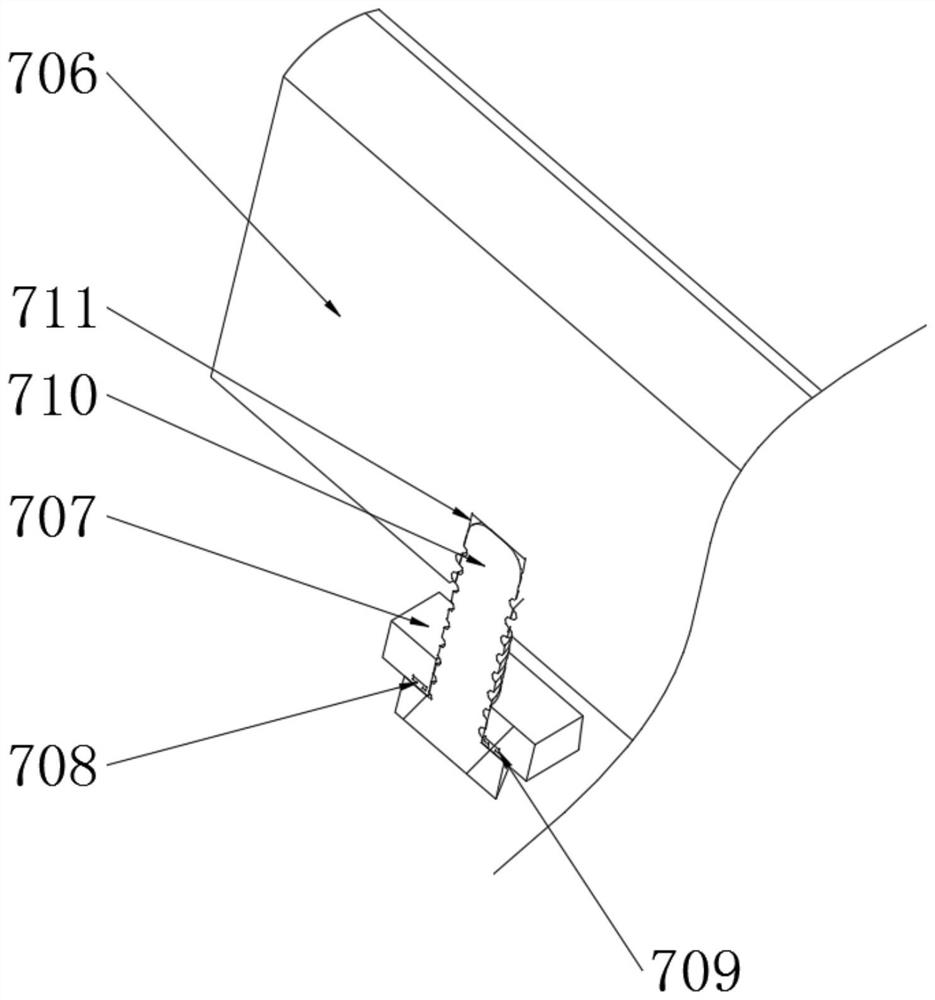

[0047] A fixed sealing assembly 7 is installed on the outer side of the shell cover 2, and the fixed sealing assembly 7 includes an arc plate 701, an arc rubber rod 702, a sealing rubber rod 703, a sealing groove 704, a corresponding baffle groove 705, a tension plate 706, and a mounting block 707 , arc rod 708, snap into arc groove 709, tension screw 710, tension thread groove 711, handle 712, buffer cylinder 713, buffer spring 714, buffer plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com