400km-hour high-speed railway embankment structure suitable for Sichuan and Chongqing layer mudstone area

A red bed mudstone and railway technology, applied in the field of subgrade engineering, can solve the problems of fiber concrete cracking, rainwater accumulation, seepage, etc., and achieve the effect of easy control of filling quality, good viscosity and creep, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

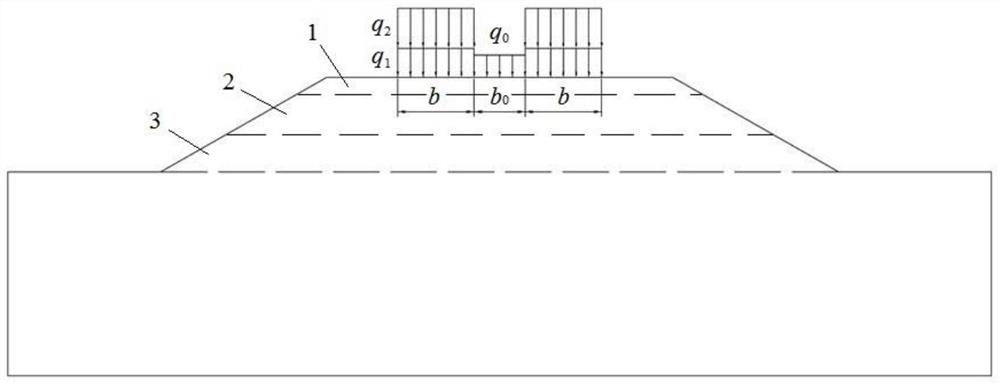

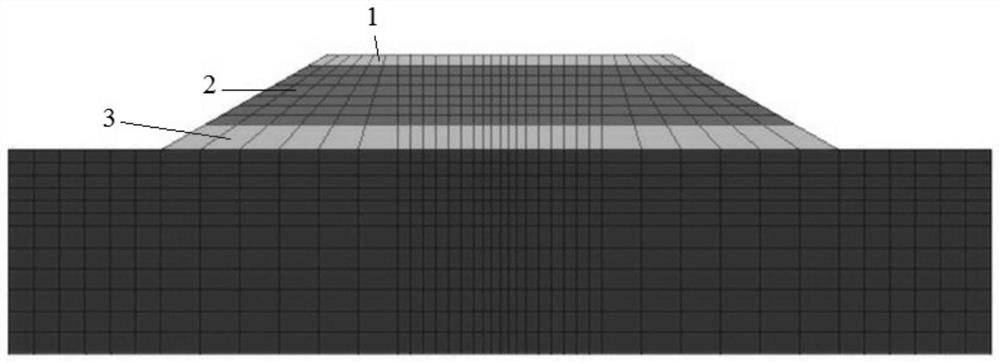

[0038] Such as figure 1 As shown, a kind of 400km per hour high-speed railway embankment structure suitable for the Sichuan-Chongqing red-bed mudstone area described in the present invention includes embankment body layer 3, subgrade bed bottom layer 2 and subgrade bed surface layer 1 filled in order from bottom to top, wherein, The foundation bed bottom layer 2 comprises described foundation bed lower bottom layer 22 and foundation bed bottom layer 21, and described foundation bed surface layer 1 comprises foundation bed lower surface layer 12 and foundation bed upper surface layer 11, and described embankment body layer 3, described foundation bed lower layer 22, described The bottom layer 21 of the foundation bed, the lower surface layer 12 of the foundation bed and the upper surface layer 11 of the foundation bed are filled in sequence.

[0039] The embankment body layer 3 is filled with red bed mudstone improved soil with a cement mixing ratio of 4%. After compacting the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com