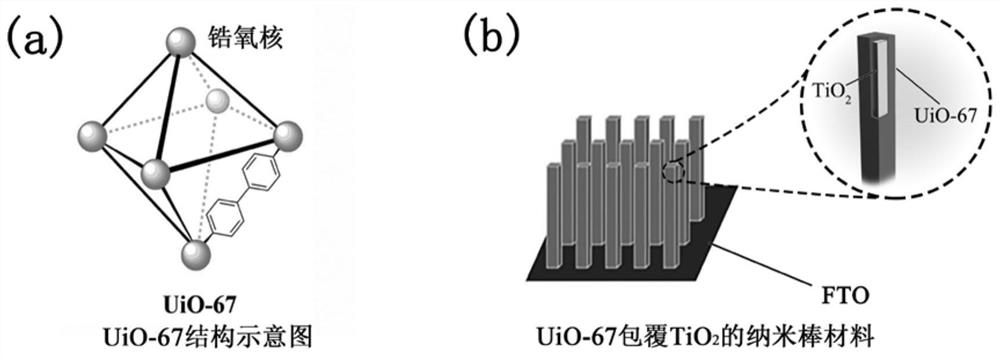

Core-shell structure of ultrathin metal organic framework material UiO-67 coated titanium dioxide nanorod, and preparation method thereof

A metal-organic framework and titanium dioxide technology, applied in nanotechnology, chemical instruments and methods, organic compound/hydride/coordination complex catalysts for materials and surface science, can solve the problem of weakening photoelectric catalytic performance and MOF volume Excessive size, low light utilization efficiency, etc., to achieve the effect of improving charge separation efficiency, improving performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

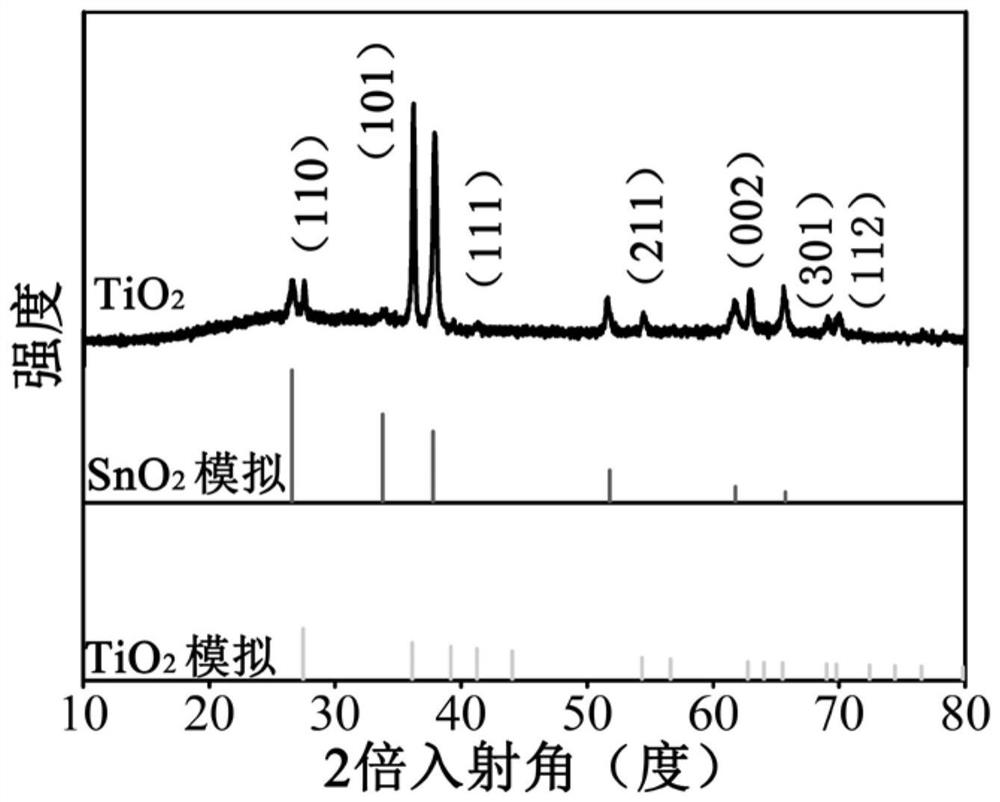

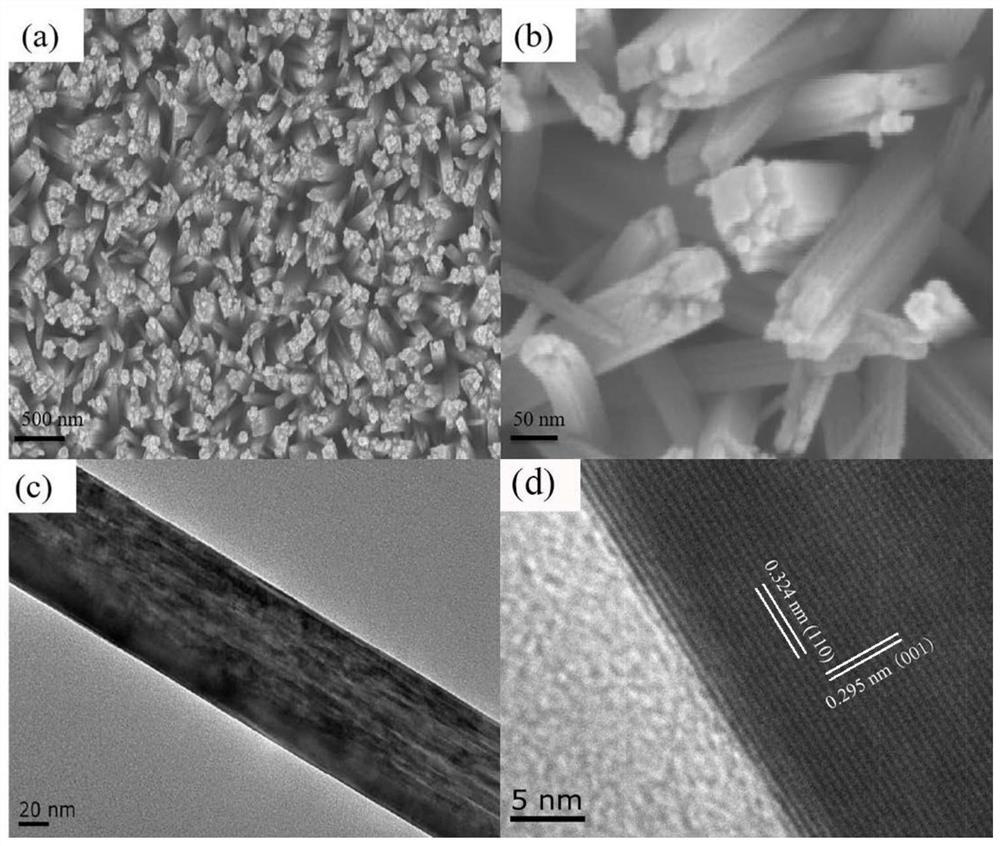

[0035] Example 1: UiO-67 coated TiO 2 Preparation of nanorods

[0036] 1) Preparation of the FTO substrate: Clean the substrate in an ultrasonic bath (ultrapure water, ethanol, acetone, ultrapure water) for 15 minutes in sequence. After cleaning, dry the FTO substrate in an oven at 80°C for 30 minutes ,spare.

[0037] 2) Preparation of hydrochloric acid solution: Dissolve 6 mL of concentrated hydrochloric acid in 6 mL of deionized water, mix and stir for 5 minutes until they are evenly mixed.

[0038] 3) TiO 2 Preparation of precursor solution: 200 μL of isobutyl titanate solution was added dropwise to the solution prepared in step 2), and stirred for 3 hours.

[0039] 4) Add 12 ml of the solution in the above step 3) into the polytetrafluoroethylene lining of the reaction kettle, immerse the pretreated FTO substrate in it, wherein the conductive side is facing down, tighten the lid of the kettle, and put the reaction kettle into 170 ℃ electric blast drying oven, and keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com