Carrying robot and warehouse logistics system

A technology of handling robots and lifting mechanisms, applied in the field of warehousing and logistics, can solve the problems of high structural dependence of cargo storage units, unfavorable modular setting of handling robots, unfavorable transportation and debugging of handling robots, etc., and achieves improved versatility and flexible use. the effect of reducing warehousing and logistics costs, improving versatility and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

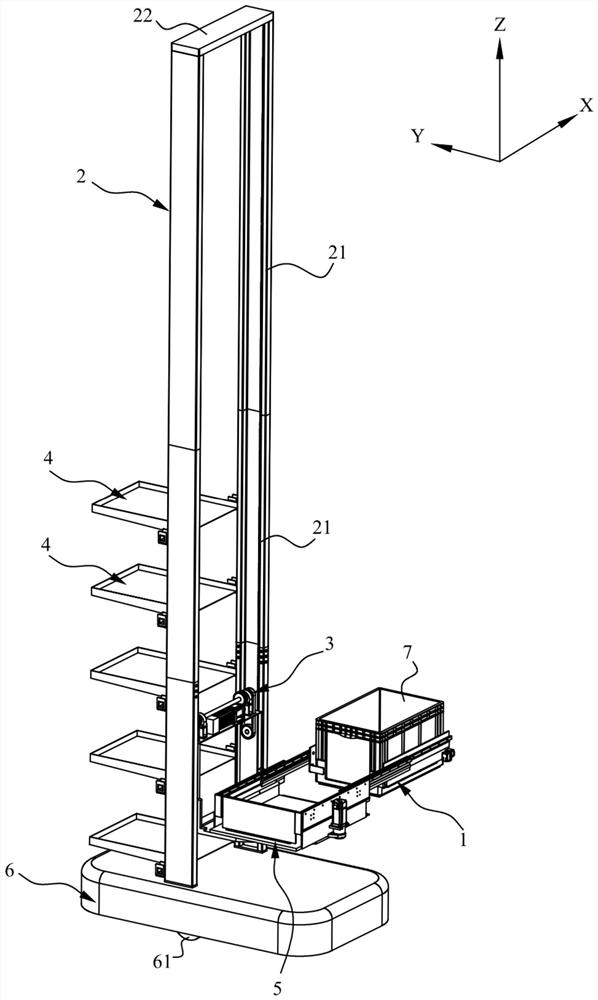

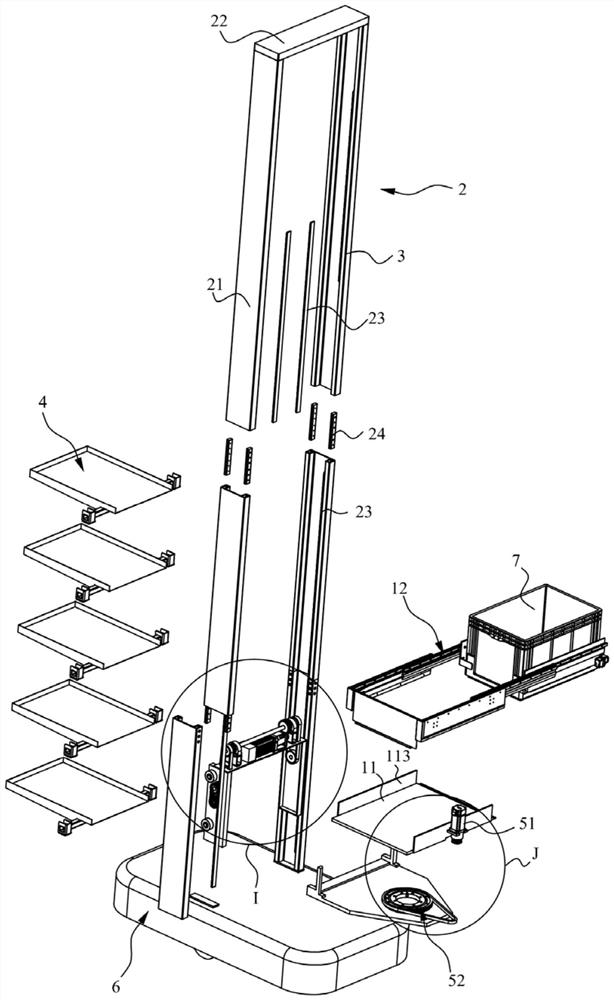

[0073] figure 1 The schematic diagram of the structure of the handling robot provided by the embodiment of the present invention, such as figure 1 As shown, this embodiment provides a handling robot, which is used to carry and pick and place the container 7, which is mainly used in the warehousing and logistics industry to pick, place and transport the container 7 stored with ordered goods or express delivery. , to implement order-based pickup or loading operations. It can also be applied to other places where cargo boxes 7 or goods need to be transported. The application of the transport robot in this embodiment is only exemplary, and this embodiment does not specifically limit it.

[0074] Such as figure 1 As shown, the handling robot provided in this embodiment includes a mobile chassis 6, a door frame 2 vertically arranged on the mobile chassis 6, and a container transmission mechanism 1 arranged on the door frame 2, and the container transmission mechanism 1 can be hori...

Embodiment 2

[0150] This embodiment provides a handling robot. Compared with Embodiment 1, the handling robot provided in this embodiment also includes a mobile chassis 6, a portal frame 2 arranged on the mobile chassis 6, and at least Two container transmission mechanisms 1 and a lifting mechanism 3 that drives the container transmission mechanism 1 to vertically lift relative to the door frame 2, each container transmission mechanism 1 includes a telescopic assembly 12, a transfer plate 11 and a box removal assembly 13. The difference is that the structure of the telescopic assembly 12 provided in this embodiment is different from that of the first embodiment. This embodiment only describes the structure of the telescopic assembly 12 in detail, and does not repeat the same structure as that of the first embodiment.

[0151] Figure 8 It is a structural schematic diagram of the container transport mechanism 1 provided by the embodiment of the present invention, as Figure 8 As shown, in ...

Embodiment 3

[0168] Figure 9 The flow chart of the box picking method provided by the embodiment of the present invention, such as Figure 9 As shown, this embodiment provides a box picking method, which uses the handling robot provided in Embodiment 1 or Embodiment 2 to pick up the target container on the inventory container, so as to realize the order picking task.

[0169] The method for taking out the box provided by the present embodiment includes the following steps:

[0170] Step S301, the control system assigns a box picking task to the handling robot;

[0171] Step S302, judging whether there is an internal container 7 in the box picking task, if so, then execute step S303, if not, then execute step S304;

[0172] Step S303, the control system plans the optimal container retrieval path according to the positions of all target containers in the container retrieval task, and in the optimal container retrieval path, the internal container 7 is not located at the last container ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com