A laminated film with a multi-layer sealing film

A laminated film and multi-layer sealing technology, applied in the field of laminated film, can solve the problems of time-consuming tearing process, inconvenient to find the port, water leakage at the break point, etc., and achieve the effect of simple and convenient operation, improved operation efficiency and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

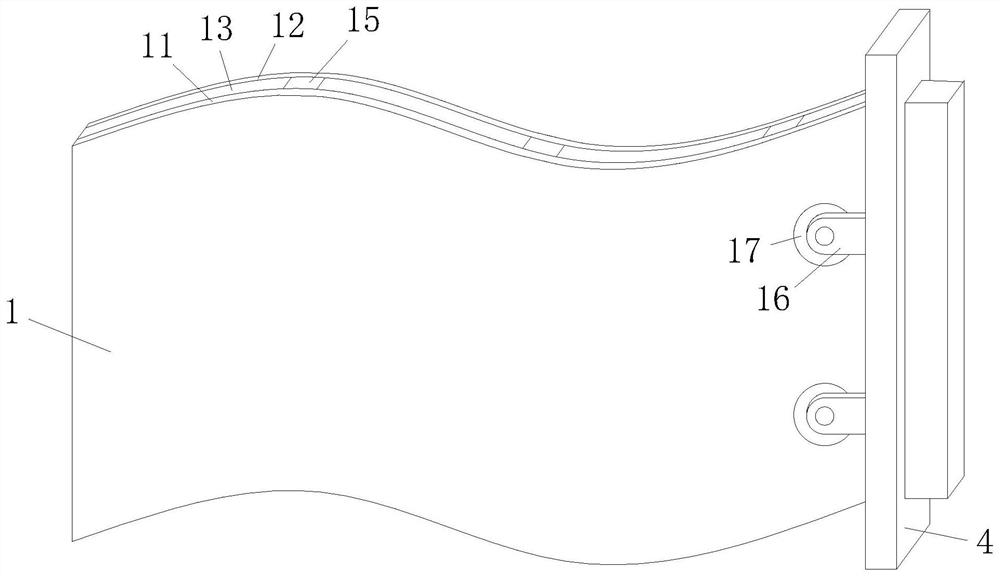

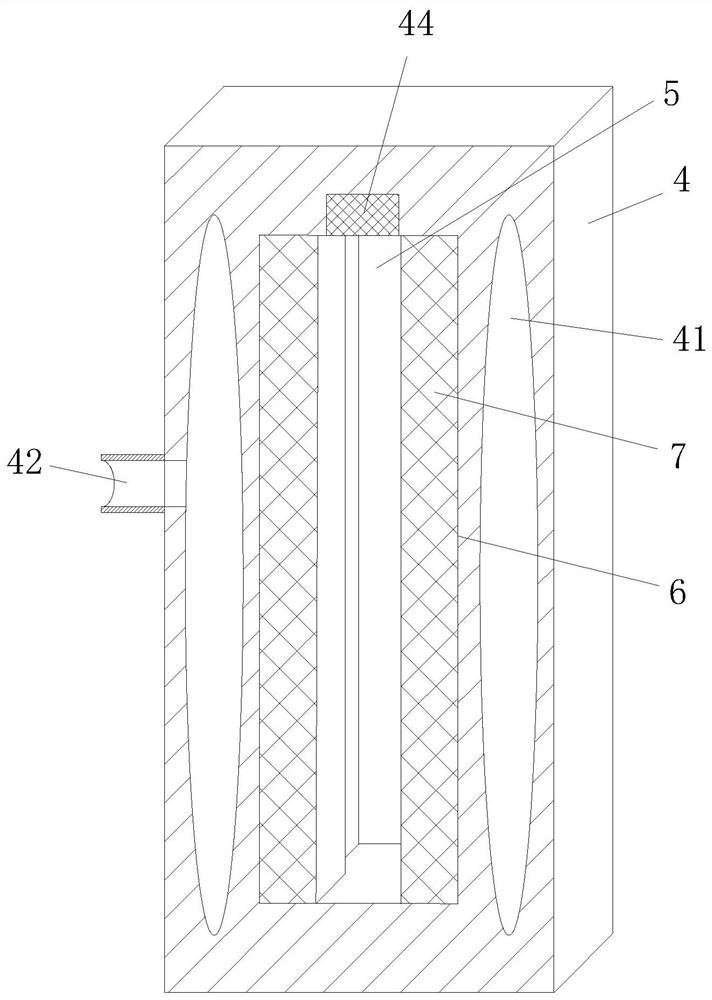

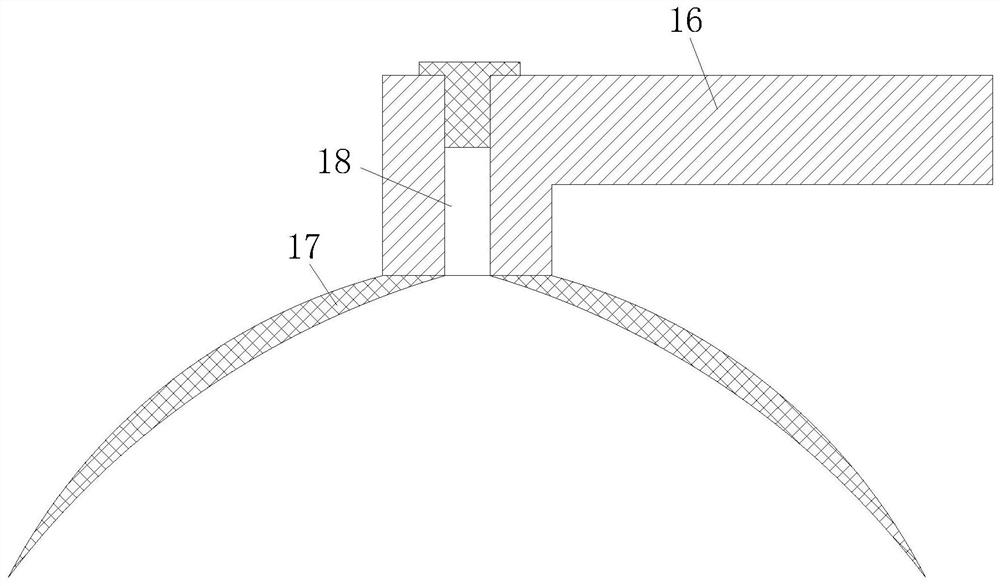

[0025] As an embodiment of the present invention, a plurality of fixing rods 16 are fixedly connected to the side surface of the positioning block 4 close to the film main body 1; the fixing rods 16 are designed in an "L" shape, and the fixing rods 16 are far away from the positioning block. One end of 4 is fixedly connected with a suction cup 17; an air groove 18 is provided in the fixed rod 16; one end of the air groove 18 is connected to the suction cup 17, and the other end is connected to the outside air, and a rubber plug is plugged in the air groove 18; When the film main body 1 is torn apart and the remaining film main body 1 will not be used temporarily, the suction cup 17 at one end of the positioning block 4 is pressed on the remaining film main body 1, and the positioning block 4 is fixed by the suction cup 17 and the clip 7. To prevent the positioning block 4 from falling, when the film body 1 needs to be used, after the rubber plug in the air groove 18 is pulled o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com