Stretching type flexible sealing manhole door

A flexible sealing, manhole door technology, applied in sealing devices, windows/doors, combustion methods, etc., can solve the problems of high labor intensity, waste of energy, smoke leakage, dust, etc., to avoid poor labor environment and reduce labor. Strength, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

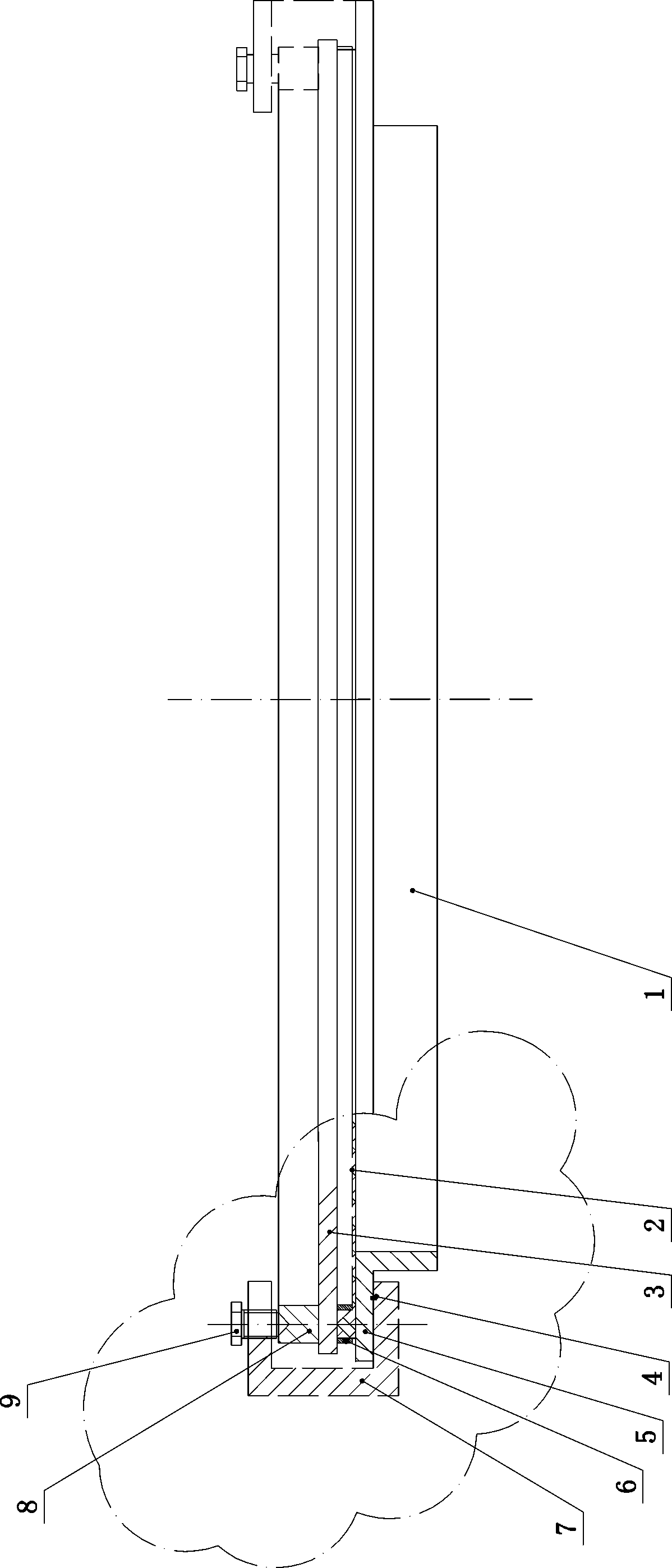

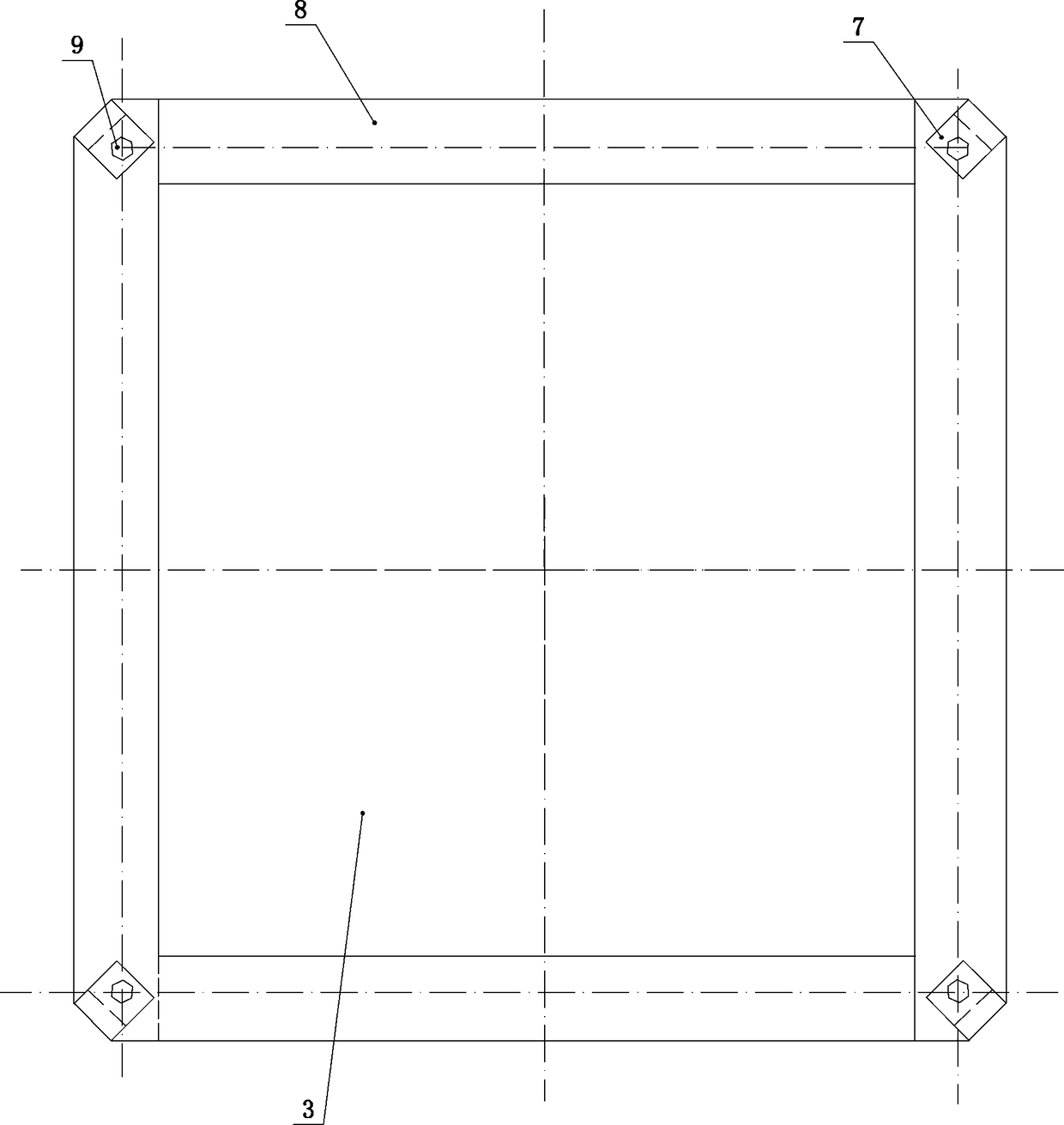

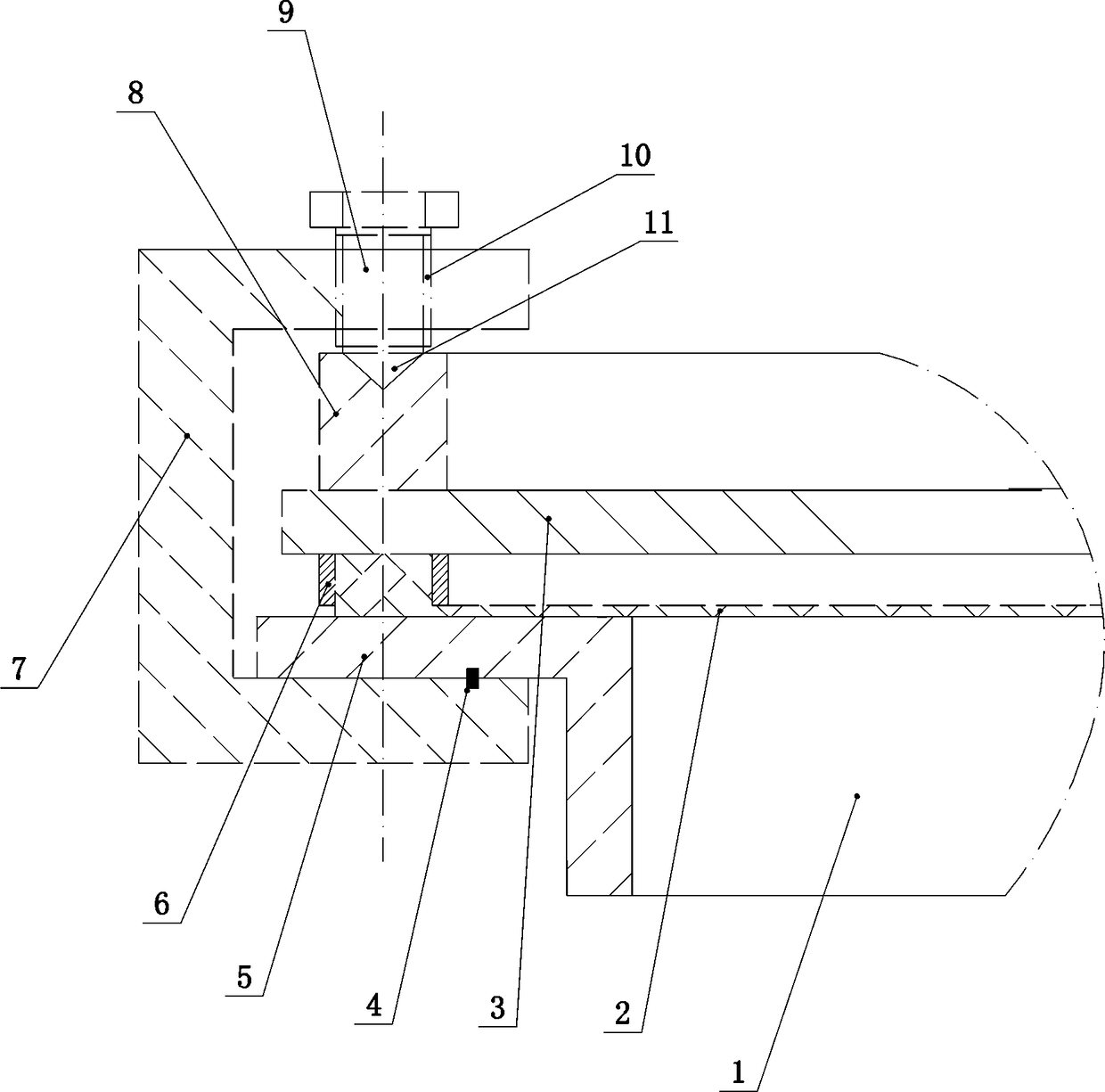

[0028] Such as Figure 1 to Figure 7 As shown,

[0029] A stretched pressure type flexible sealed manhole door, comprising a door frame 1, with a pressing edge 5 on the edge of the door frame 1, a corresponding door panel 3 is provided on the outside of the door frame 1, and a flexible sealing bead 2 is fixedly connected to the inside of the door panel 3. The bead 2 is in airtight contact with the blanking edge 5. The outer surface of the door panel 3 is fixedly connected with a rigid beading 8 which corresponds to the inner and outer blanking edges 5 of the door frame 1. The outer surface of the rigid beading 8 is recessed with a plurality of pressing grooves. 11. A rigid clamp 7 is provided where the stretched groove 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com