Pressure-adjustable visual calendering bubble scarification device

A technology of pressure and bubble scratching, applied in the field of tire machinery manufacturing, can solve the problems of unadjustable pressure and inability to visualize the bubble scratching device, and achieve the effect of increasing service life and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

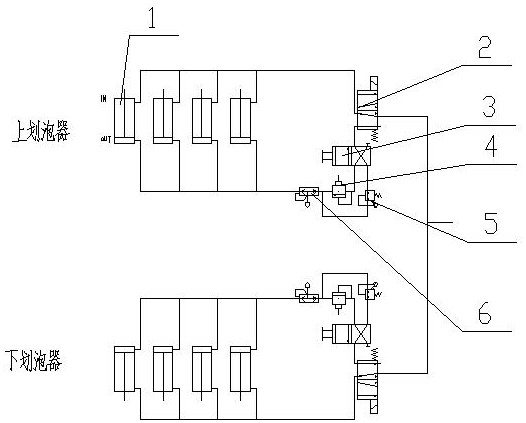

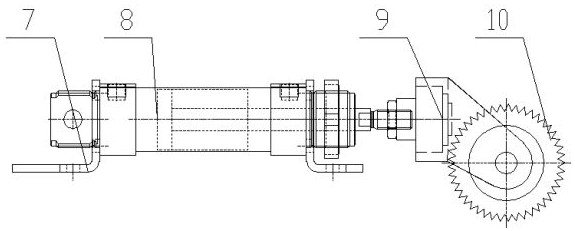

[0018] When the calendering linkage production line is started, the solenoid valve (2) operates and passes through the manual valve (3). The manual valve can choose the air path to pass through the pressure regulating valve (5) or the electric proportional valve (4). By adjusting the pressure of the pressure regulating valve or After the pressure of the electric proportional valve, the gas path enters the end of the cylinder (8), and the cylinder stretches out. The cylinder is fixed on the traverse device of the air bubble device through the cylinder mounting bracket (7), and the stabbing wheel (10) is installed on the cylinder rod head of the cylinder (8) through the stabbing wheel bracket (9). The wheel is pressed on the calender roll and slides back and forth through the traverse device, thereby playing the role of pinching air bubbles. When the pressure is found to be too high or too low during the production process, the pressure can be readjusted through a pressure regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com