Food cleaning table

A technology for cleaning table and food, applied in the field of food cleaning table, can solve the problems of uneven local concentration of cleaning liquid, affecting food cleaning effect, external environmental pollution, etc., and achieve the effects of accelerating fluidity, improving cleaning effect, and speeding up conveying rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

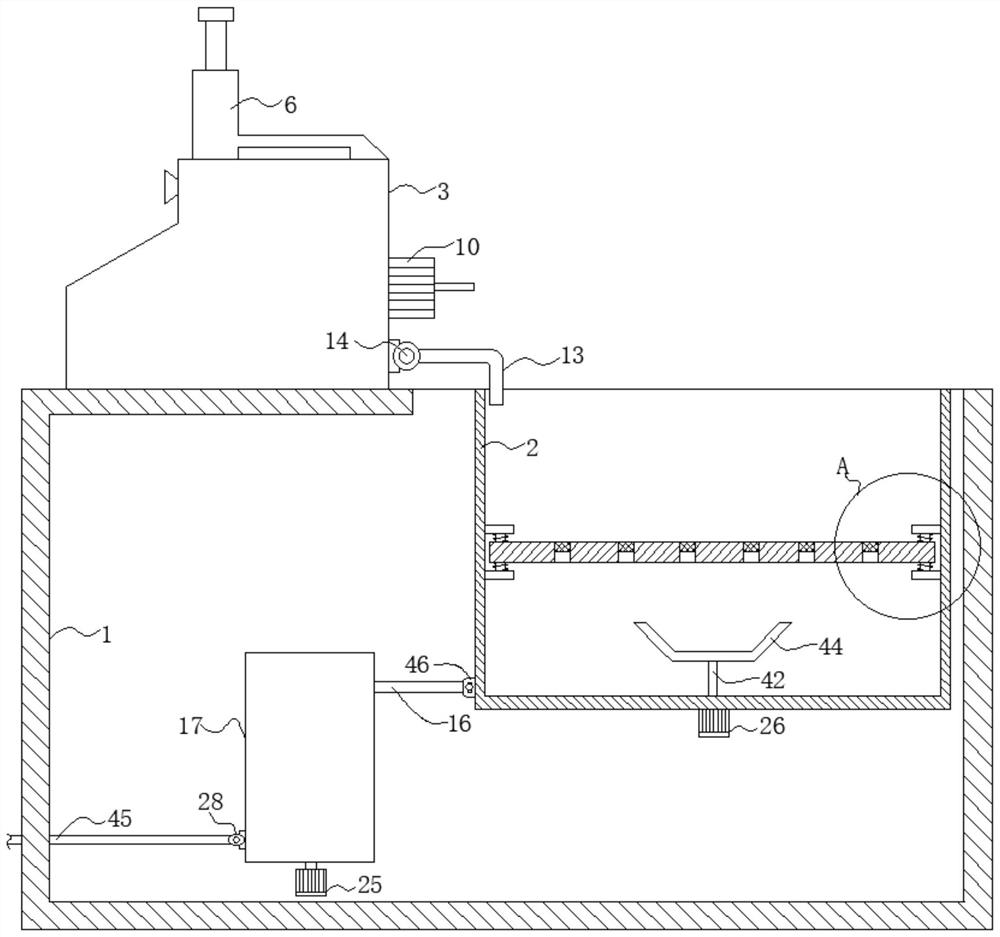

[0030] Please combine Figure 1 to Figure 4 1. The food cleaning table includes a hollow table body 1, one side of the top of the table body 1 has an opening, and a cleaning tank 2 with an open top is fixed in the opening, and a water outlet 15 is provided on one side of the cleaning tank 2.

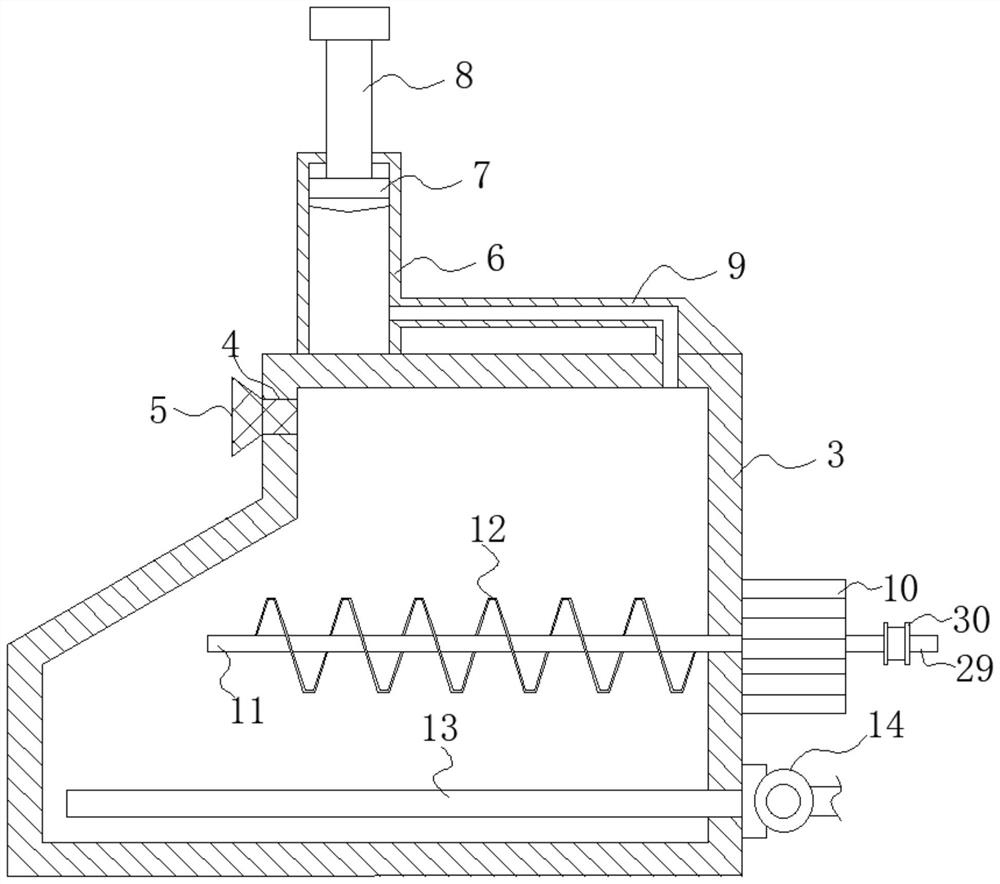

[0031] The other side of the top of the table body 1 is provided with an infusion assembly, the infusion assembly includes a cleaning solution tank 3, an injection port 4 is opened on one side of the cleaning solution tank 3, and a cock 5 for blocking the injection port 4 is installed at the injection port 4 A proper amount of water and cleaning agent can be injected into the cleaning solution tank 3 through the injection port 4, and the cleaning solution is formed after the water and cleaning agent are mixed. In this embodiment, the cock 5 and the injection port 4 are connected by threads, and a silicone grease sealing ring is provided at the threaded connection between the cock 5 and t...

Embodiment 2

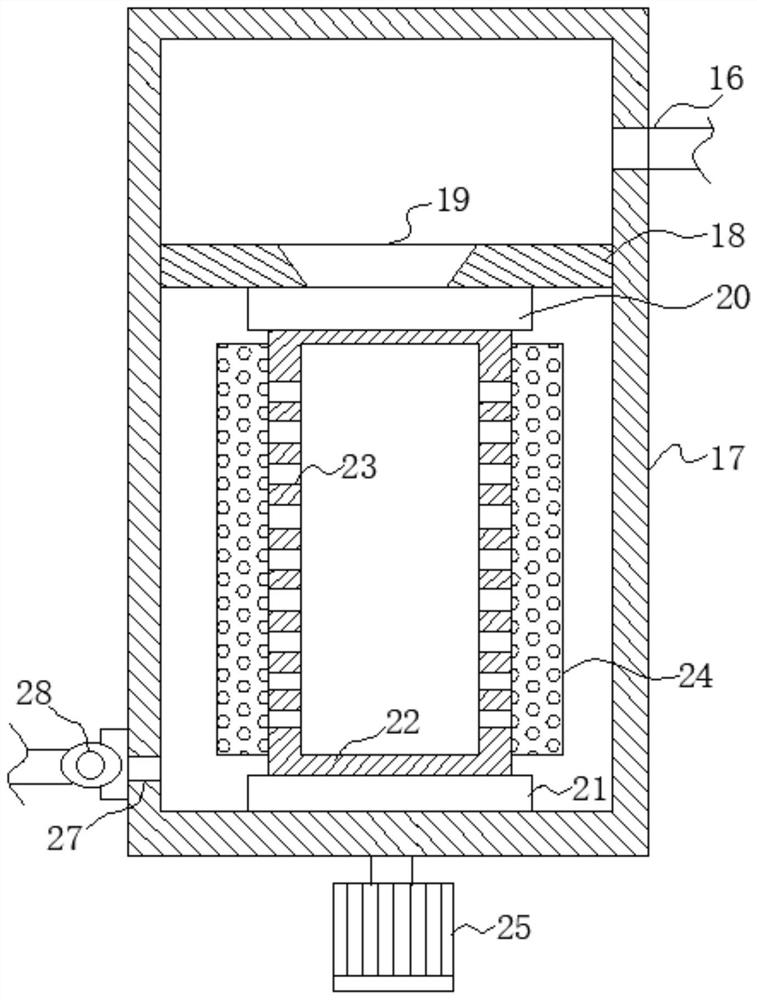

[0044] Please combine Figure 5 to Figure 6 , present embodiment 2 is a kind of improved scheme of embodiment 1, another output shaft of biaxial motor 10 is connected with shaft two 29, and the other end of shaft two 29 is connected with pulley one 30, and the bottom of cleaning tank 2 is provided with limited The position cover 37 and the limit cover 37 are slidingly inserted with a rotating rod 38, and the rotating rod 38 can rotate on the limit cover 37. One end of rotating rod 38 is connected with belt pulley 2 39, is connected by belt 40 between belt pulley 1 30 and belt pulley 2 39, and the other end of rotating rod 38 is connected with bevel gear 1 41, and the bottom end of vertical shaft 42 is connected with bevel gear. The bevel tooth two 43 that tooth one 41 meshes.

[0045] The working principle of this embodiment 2 is that the output shaft of the biaxial motor 10 drives the first pulley 30 to rotate, the second pulley 39 and the first pulley 30 keep synchronous mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com