Bearing and method for producing a bearing

A technology for bearings and bearing rings, which is used in the manufacture of bearings, especially in the field of rolling bearings or sliding bearings, which can solve the problems of work consumption, damage to measuring components, etc., and achieve the effect of avoiding enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

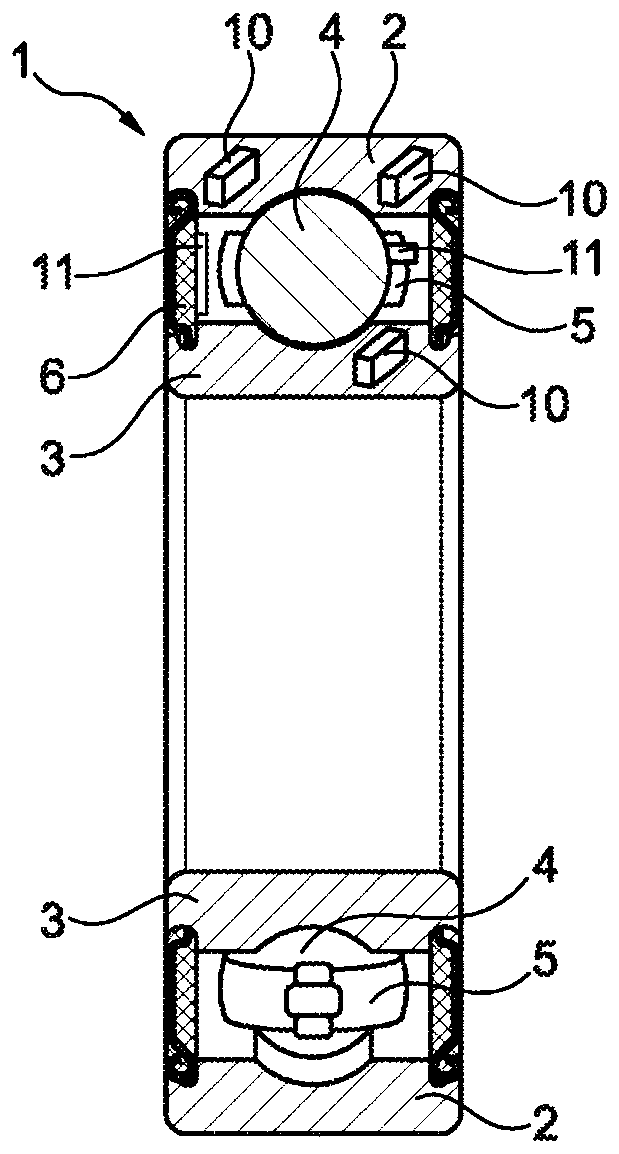

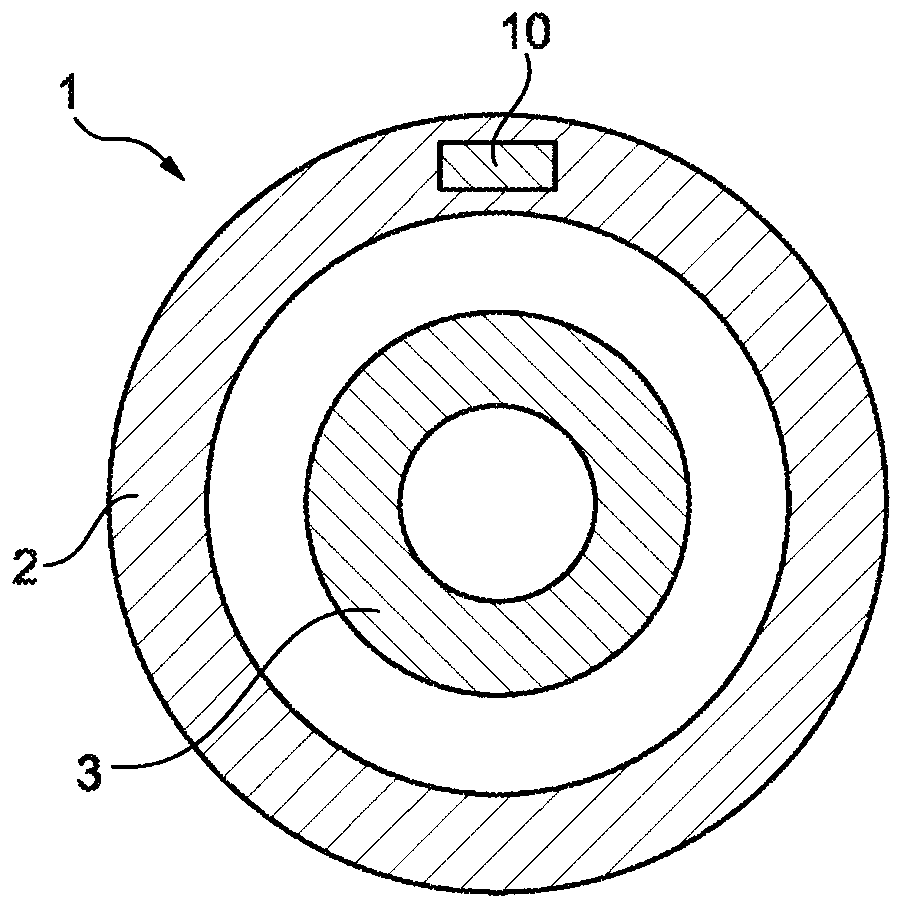

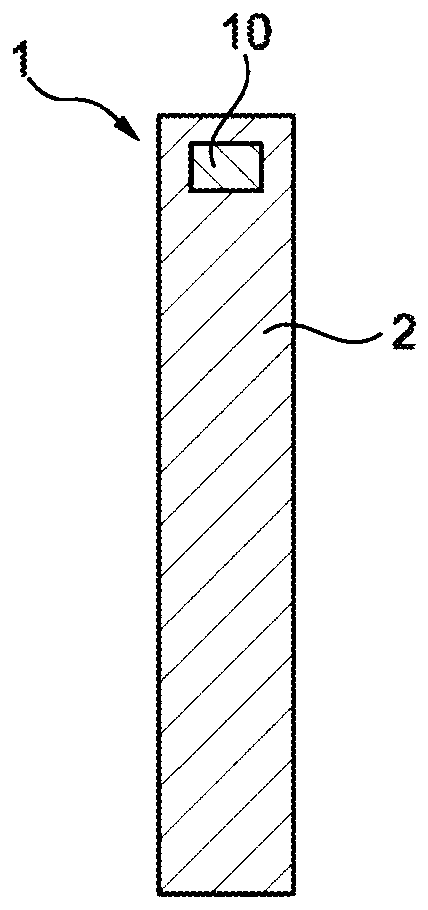

[0029] exist figure 1 shows a bearing 1 designed as a rolling bearing according to a first exemplary embodiment of the invention. The bearing 1 also has an outer bearing ring 2 , an inner bearing ring 3 rotatable relative to the outer bearing ring 2 , and rolling elements 4 arranged between the outer bearing ring 2 and the inner bearing ring 3 as bearing components. The rolling elements 4 are arranged in a rolling element cage 5 . The inner space of the bearing 1 , that is to say the space between the outer bearing ring 2 and the inner bearing ring 3 is sealed via the sealing element 6 so that the lubricant present in the inner space cannot escape undesirably, however, the inner space also Not damaged by intruding dirt.

[0030] The bearing 1 has a plurality of functional modules 10 designed as sensor modules each for detecting at least one measured variable and is also referred to as a sensor bearing. The functional module 10 can have sensors for detecting the temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com