Real-time detection method for compactness of poured vault

A technology for real-time detection and compactness, which is applied in the direction of measuring devices, material inspection products, and processing detection response signals, etc., can solve problems such as inconvenient operation and construction, and achieve the effect of meeting the requirements of vault compactness monitoring and simple and reliable testing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

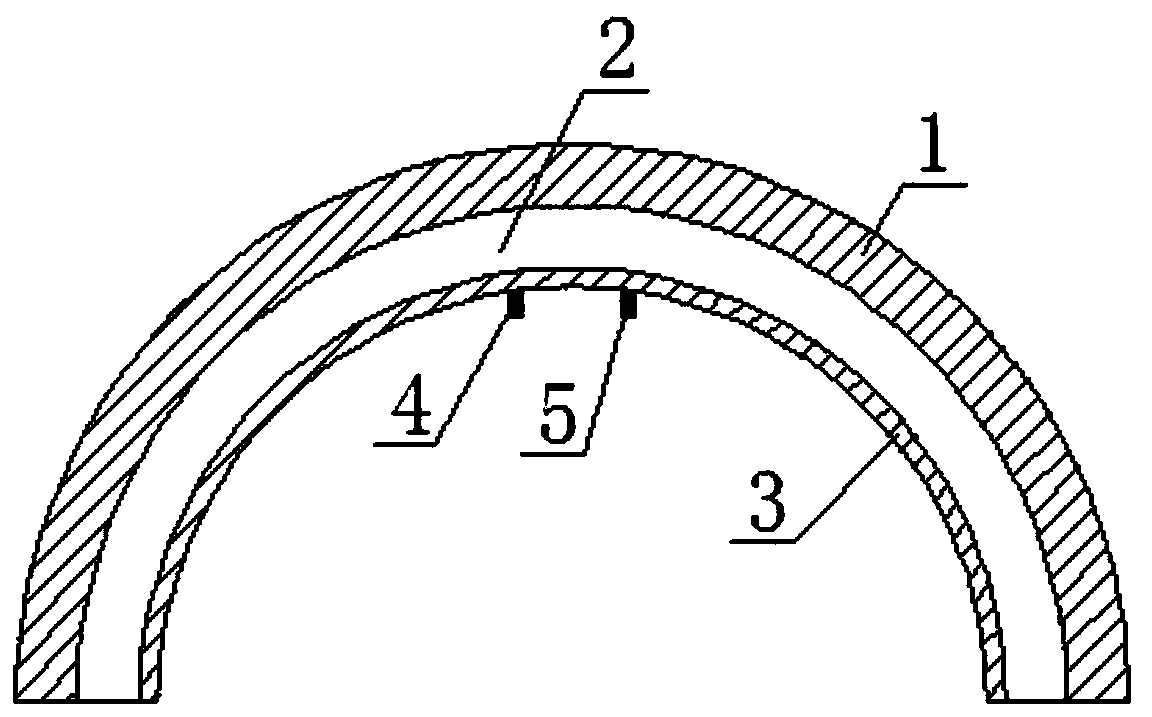

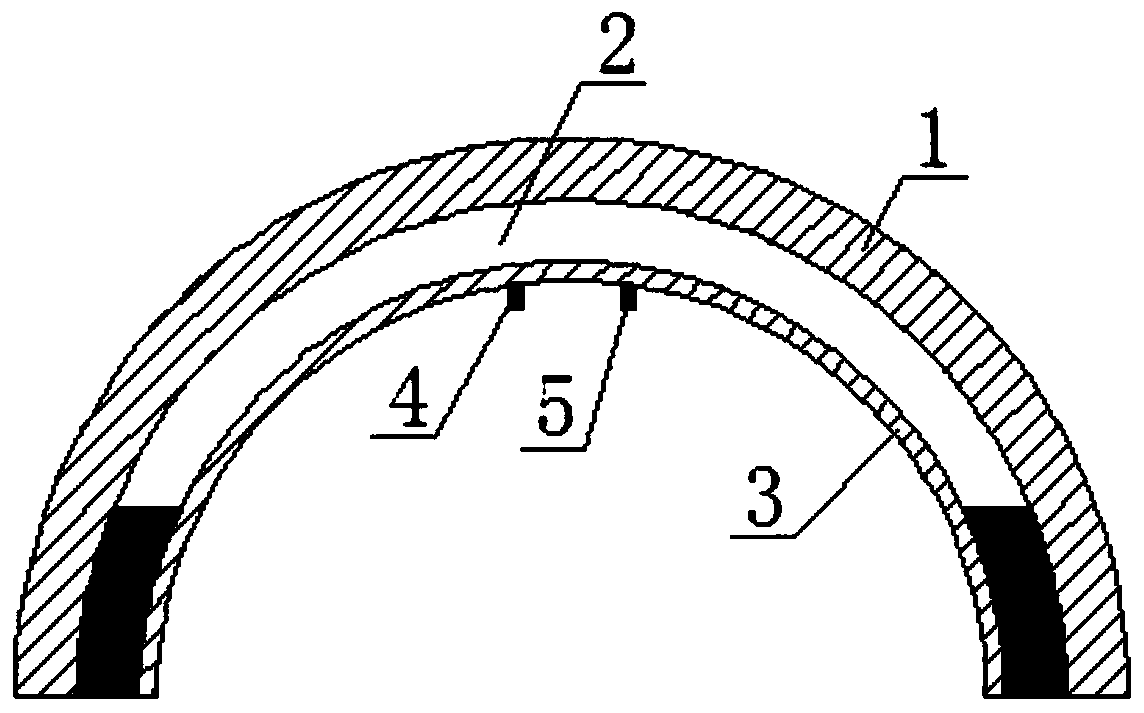

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

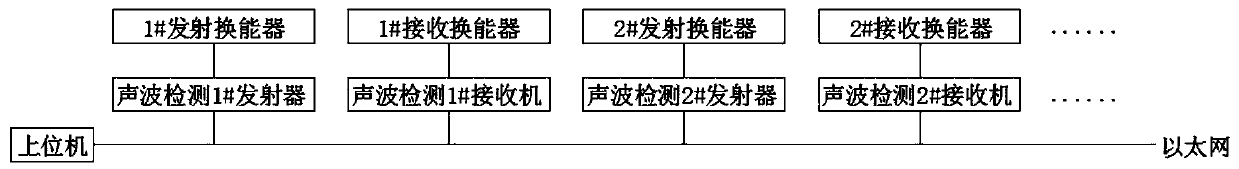

[0039] Such as figure 1 As shown, a kind of perfusion vault compactness real-time detection method provided by the invention, its specific steps are as follows:

[0040] A. Install the acoustic wave testing device under the vault template;

[0041] B. Establish an off-line sound wave waveform database on the host computer through the method of actual measurement;

[0042] C. During the construction process, the transmitting unit of the acoustic wave testing device transmits the acoustic wave signal to the vault template in real time, and receives it in real time through the receiving unit of the acoustic wave testing device;

[0043] D. The host computer compares the detected waveform data transmitted by the receiver with the data in the acoustic wavefor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com